► Description:

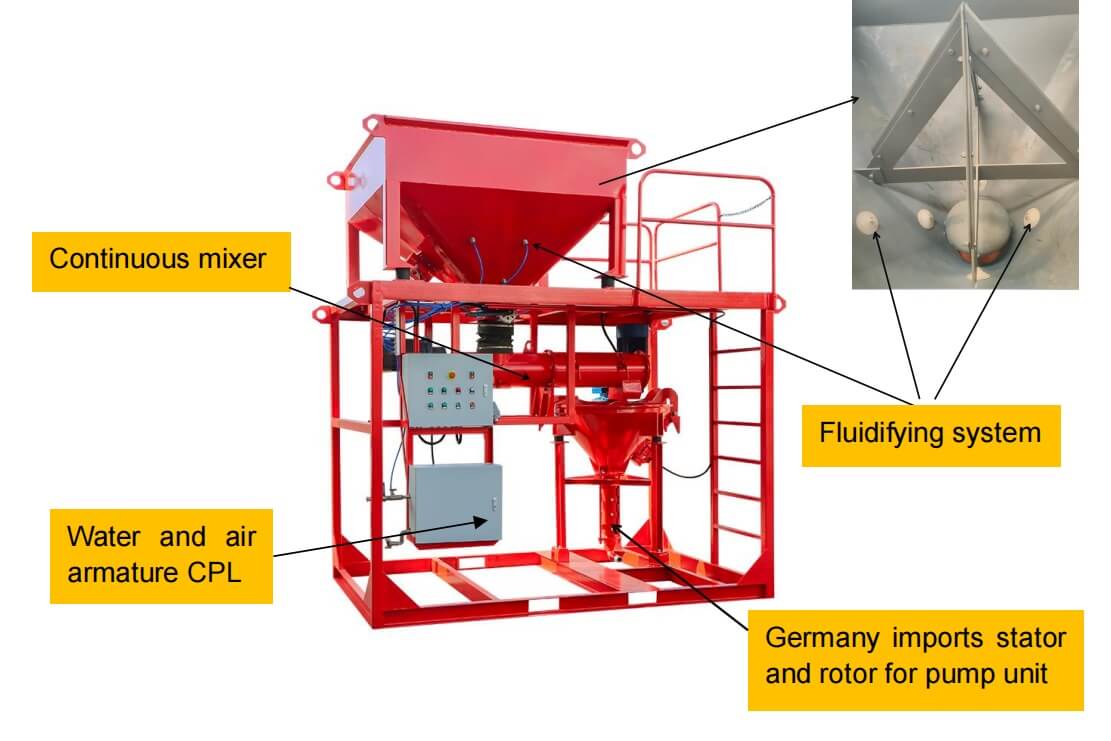

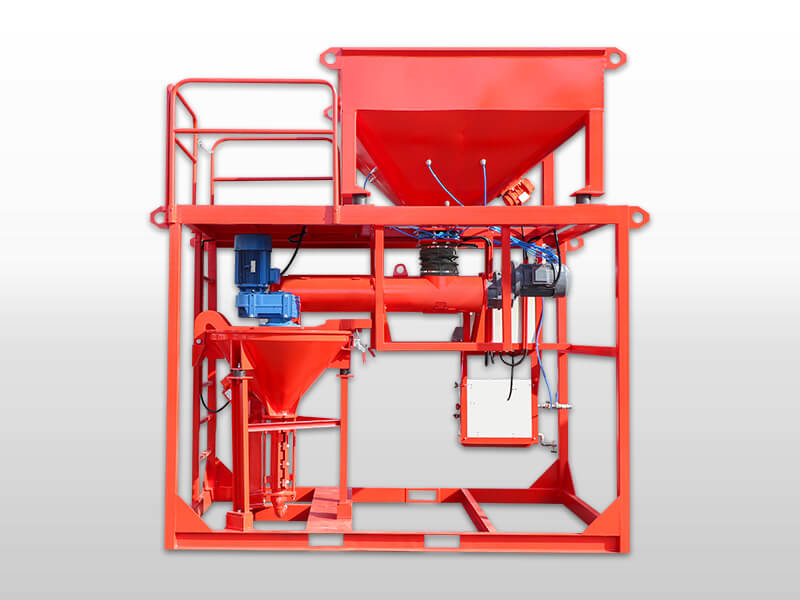

LTS-40E/S Tundish spraying machine is a highly advanced integrated device that integrates a stirring device, a pump device and a spraying device. Tundish spraying machine is used for tundish spraying in metallurgy, casting and other related industries. It is designed to spray refractory materials during tundish repair in steel mills. The integration of the Ø250 continuous mixer and 2L7 vertical screw pump ensures uniform mixing of high-quality refractory materials. The equipment is widely used in modern steel mills equipped with continuous casting units, ensuring smooth and uninterrupted operation.

Leadcrete is one of the most experienced Tundish spraying machine manufacturers and manufacturers in China. Our professional team uses first-class metal materials to design effective and fully functional Tundish spraying machines suitable for a wide range of industrial uses. The machines are very durable and widely used due to their precise dimensions and optimal performance. We can also provide customized services for Tundish spraying machines to our customers.

► Working Principle:

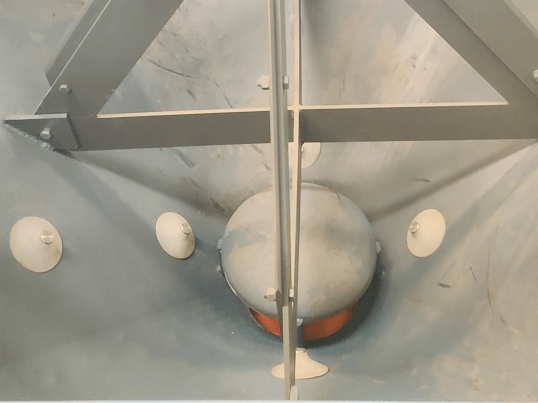

The dry pre-mixed slurry mass is transferred from large sacks into the material hopper. The combination of a fluidizing unit and a vibrating device ensures a constant flow of the dry material and facilitates the safe charging of the continuous mixer. Within the continuous mixer, the dry material is continuously blended with an adjustable volume of water to create a top-quality spray slurry with consistent texture and properties.

The completely mixed wet material streams from the continuous mixer into the wet mortar hopper of the screw pump. The screw pump is equipped with a funnel-shaped wet mortar hopper that has a concentric pump drive. A vibrating element, together with the conveying shaft in the wet mortar refractory hopper, ensures an uninterrupted and stable flow of the slurry masses toward the suction opening of the vertically positioned screw pump.

The screw pump transports the refractory material through pressure-resistant hoses to the spray gun for subsequent processing. The gunning material is applied either manually or fully automatically, without any wastage, by a spray manipulator in even layers on the interior walls of the Tundish. The spraying process is regulated by the spray nozzle.

► Application:

LTS-40E/S Tundish spraying machine is mainly used to spray a layer of refractory material on the inner surface of the tundish to prevent the erosion of the tundish by the high-temperature molten steel, improve the service life of the tundish, and ensure the quality of the molten steel and the stability of production.

LTS-40E/S Tundish spraying and gunning machine is applicable in various industrial settings where tundish operations are involved. It is particularly useful in steel manufacturing plants that utilize continuous casting processes. The tundish spray machine and its associated components, such as the continuous mixer, screw pump, and spray gun, play a crucial role in the tundish repair process. By ensuring a smooth and efficient flow of the refractory slurry, it helps in coating the inner walls of the tundish effectively, thereby enhancing the tundish's durability and performance. This is essential for maintaining uninterrupted production in steel mills, as a well-maintained tundish contributes to the quality of the final steel product. Additionally, the machine's ability to mix dry and wet materials in a controlled manner and transport them through pressure-resistant hoses allows for precise application of the refractory material, reducing material waste and increasing overall operational efficiency.

In summary, the Tundish spray machine is one of the indispensable and important equipment in the metallurgical and casting industries. It can improve production efficiency, ensure product quality, and continuously upgrade and improve with the continuous development of technology.

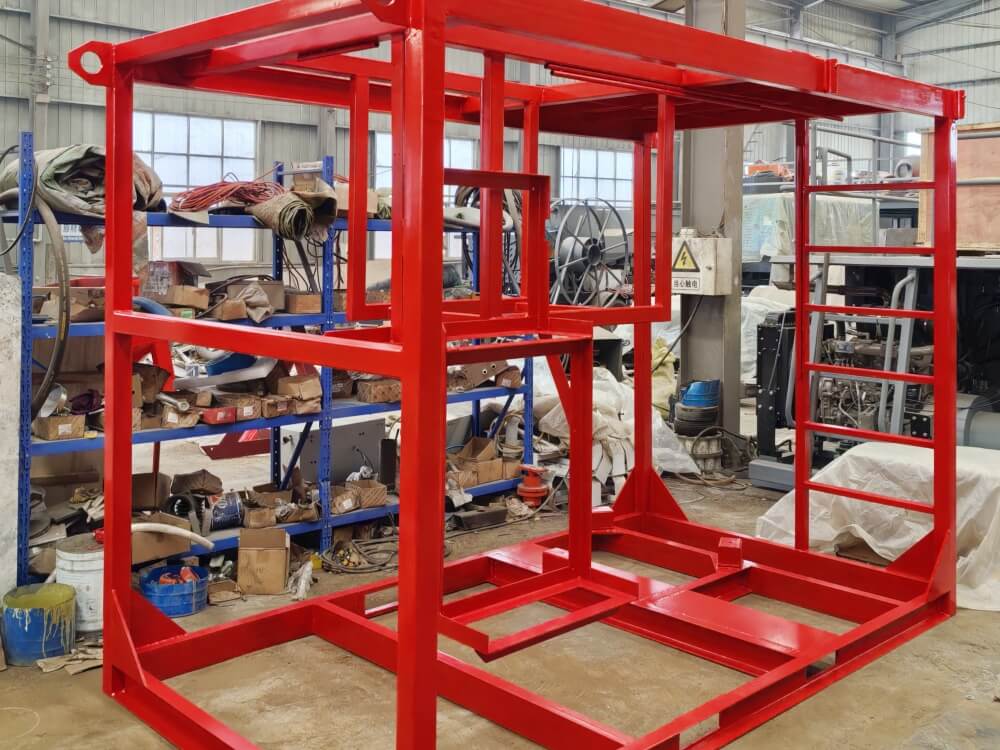

► Features:

♦ Frame

|

Model |

LTS-40E/S Tundish spraying machine |

|

Useful volume of the hopper |

1.5m³ |

|

Mixer motor |

5.5Kw |

|

Mixing output |

40L/min |

|

Pump motor |

7.5Kw |

|

Pump output |

40 L/min |

|

Conveying pressure |

20bar, Max. 40 bar |

|

Conveying distance, horizontally |

Max. 40m |

|

Conveying height |

Max. 20m |

|

Max. aggregate size |

6mm |

|

Hose connection to the pump |

ID32 |

|

Required water connection |

ID25/3bar |

|

Required air connection |

ID25/6bar |

|

Required compressed air |

300 L/min for spraying |

|

Operating voltage |

380V,50Hz 3phase, customized voltage |

|

Overall dimension |

3000(L)×1780(W)×3250(H)mm |

|

Weight |

1635Kg |

|

Note: |

|

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS