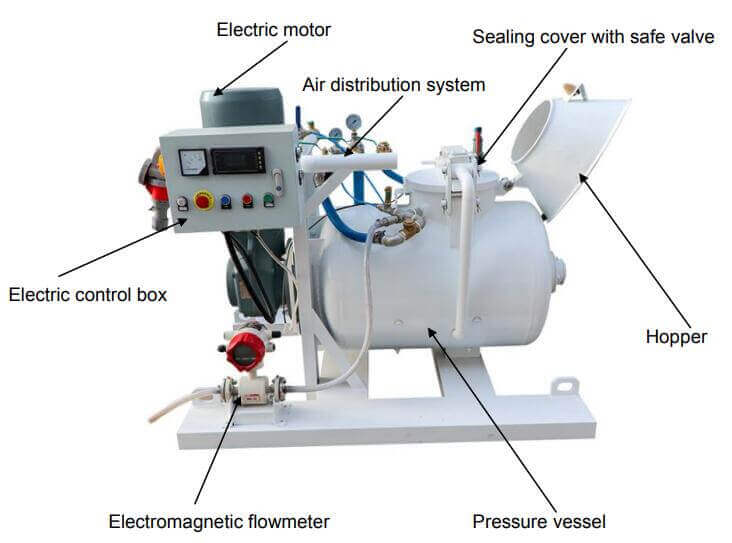

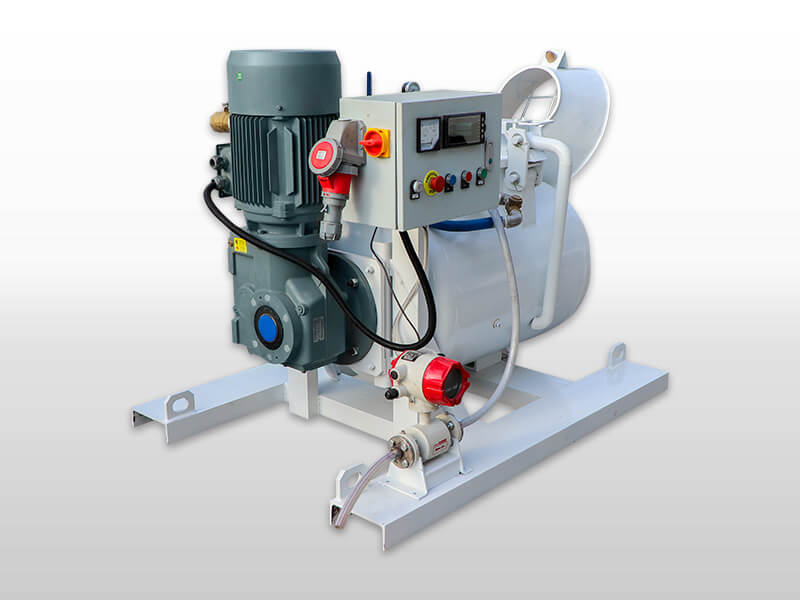

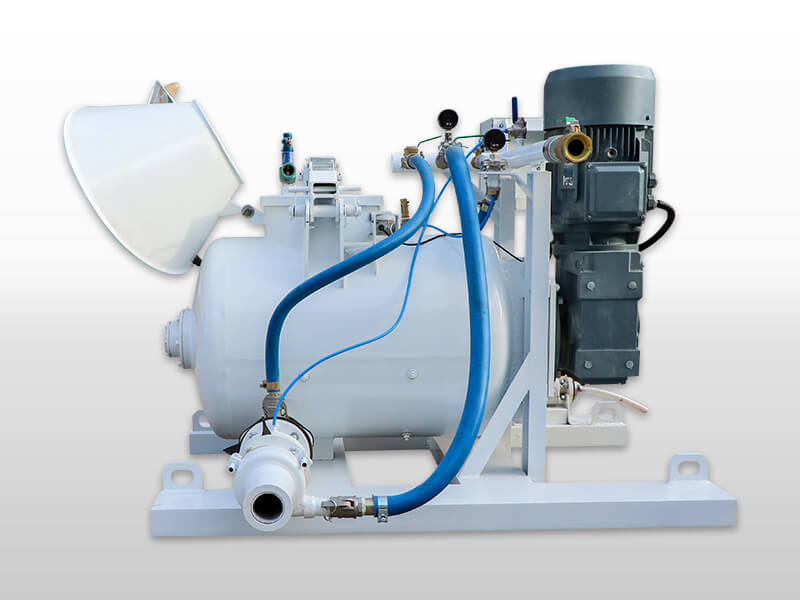

LDP Pneumatic refractory mortar mixing and conveying units are specifically designed for the transport of solid and moistened mortar, concrete mixtures, and refractory castables.

These units are ideal for use in the metallurgical industry, providing permanent linings for ladles, tundish, and blast furnace runners, as well as for industrial and melting furnaces in the glass and aluminum industries. Additionally, they are applicable in the construction industry for concreting building bases, floors, and large concrete areas.

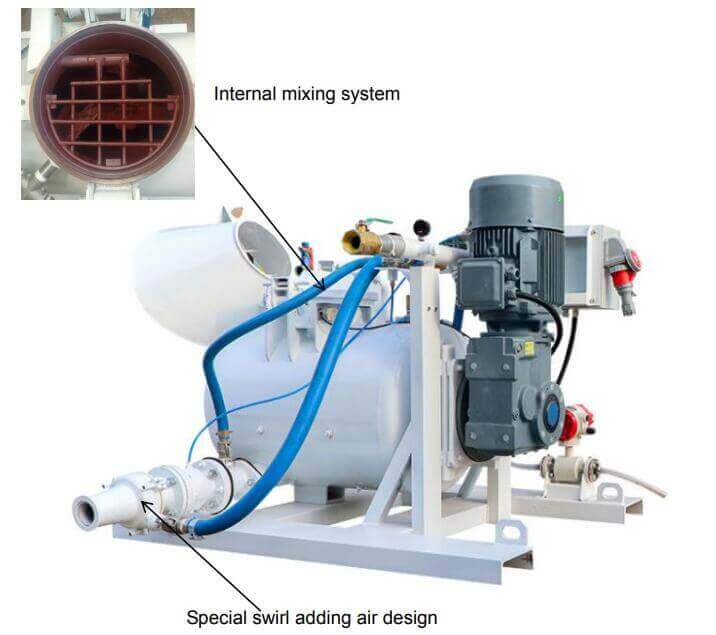

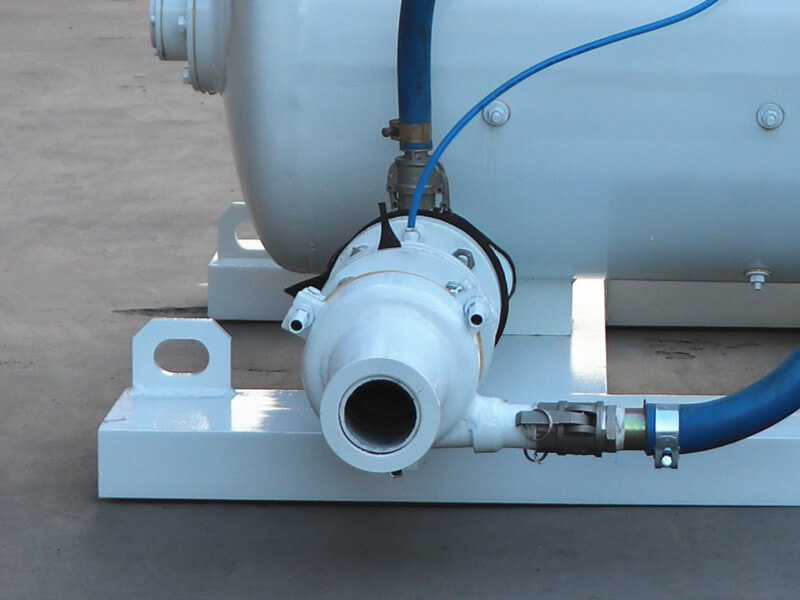

The mixture contained within the pressure tank is agitated by the movement of mixing blades and the action of compressed air. The mixing blades simultaneously move the mixture and direct it towards the tank's discharge port. Additionally, compressed air introduced at a lower position enters the conveying hose, ensuring the mixture moves uniformly through the transport hoses. The mixture travels through the conveying hose in agglomerates, and a unique swirling air path design prevents significant fluctuations in the material flow.

► Application:

1. Manufacture and transport of solid and damp concrete mixture and refractory materials.

2. In civil engineering, for structure foundation floor and large concrete area

3. In metallurgy, for pig iron production, spout and gutter concreting, in steel

► Features:

1. Saving of manpower and cost;

2. Exact electronic water dosage system;

3. Rigid and compact mixing and conveying unit;

4. Conveying materials that are difficult to pump;

5. Mixture of consistently homogenous mixing quality;

6. Easy to handle system regarding installation, conveying, and cleansing.

|

Model |

LDPX200 |

LDPX500 |

LDPX600 |

|

Output capacity |

4m3/h |

10m3/h |

10m3/h |

|

Useful vessel volume |

200L |

500L |

600L |

|

Total vessel volume |

250L |

660L |

800L |

|

Max. Grain size of mixture |

16mm |

32mm |

32mm |

|

Electric motor power |

11Kw |

22Kw |

30Kw |

|

Conveying distance |

Horizontal 100m, Vertical 40m |

||

|

Operating pressure |

0.2~0.4Mpa |

0.2~0.4Mpa |

0.2~0.4Mpa |

|

Max. vessel pressure |

0.8Mpa |

0.8Mpa |

0.8Mpa |

|

Required compressed air |

4~6m3/min |

5~10m3/min |

5~10m3/min |

|

Dimension |

1.55x1.55x1.25m |

2.88x1.4x1.85m |

3.32x1.4x1.85m |

|

Weight |

668Kg |

1640Kg |

1740Kg |

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS