►Description:

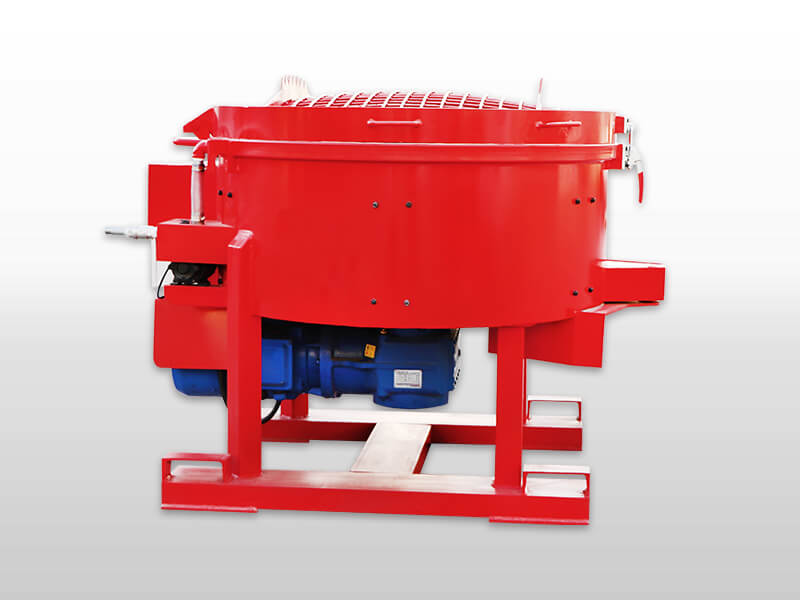

LRM500 500kg refractory concrete mixer excels at blending refractory materials and castables. Offered in both stationary and conveniently mobile configurations, it delivers superior performance for all your mixing needs.

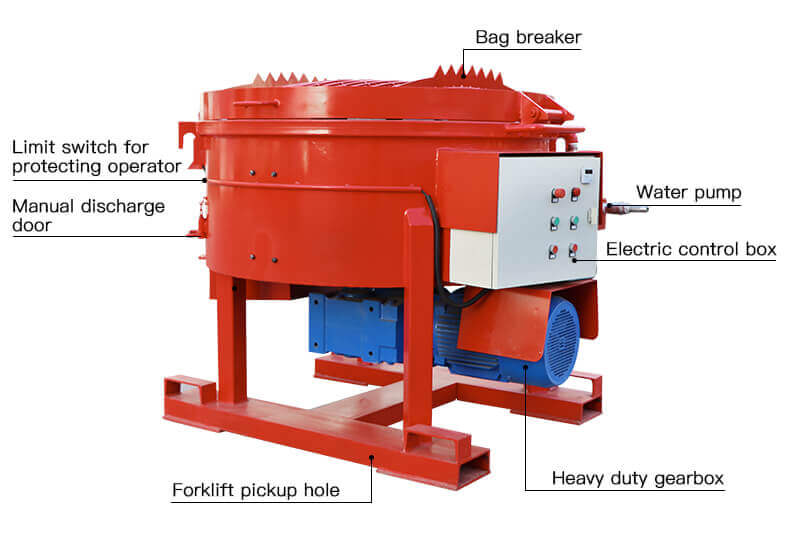

For enhanced jobsite maneuverability, the LRM500 boasts integrated forklift pockets within its frame. To combat wear and tear, the mixer features a highly durable steel lining that safeguards both the bottom and interior walls. Furthermore, its five specialized mixing arms work together to achieve uniform mixing of refractory materials, eliminating any sticking or clumping.

►Application:

LRM500 500kg capacity refractory concrete mixer is commonly used in the construction industry to mix various materials, including concrete and refractory mixes. When it comes to refractory works, such as those required in high-temperature environments like kilns, furnaces, and incinerators, the mixer needs to be able to handle specific types of refractory materials that may have different properties than standard concrete.

Refractory concrete typically includes components designed to withstand high temperatures and resist thermal shock, chemical attack, and mechanical wear.

Refractory concrete cement mixer are mainly used in the following industries:

>Steel Industry

> Aluminium Industry

>Cement Industry

>Power Generation

> Refineries

>Lime Industry

>Foundry

>Glass Industry

>Ceramic Industry

>Incinerators

► Features:

LRM500 500kg pan mixer concrete for refractory works is designed for efficient and convenient on-site operations, particularly suitable for applications requiring high-quality mixing, such as concrete or refractory mixes.

1. Pan Mixer:

This refers to a type of mixer that uses a horizontal circular pan where the mixing occurs. The material is placed inside the pan, and a blade or a series of blades rotates within the pan to blend the ingredients thoroughly.

2. Special Designed for Site Operation:

This indicates that the 500kg capacity refractory concrete mixer is optimized for use at construction sites or similar locations where space, mobility, and ease of use are critical factors. It may include features like compact design, easy maneuverability, and robust construction to withstand rough conditions.

3. Fast Mixing Speed and Homogeneous:

The 500kg refractory cement mixer is designed to blend materials quickly and evenly, ensuring that the final mixture is consistent throughout. This is crucial for maintaining the quality and performance of the materials being mixed.

4. Compact Structure:

A compact design allows the mixer to fit into smaller spaces, making it easier to transport and operate in tight job sites. It also helps reduce the footprint of the equipment on-site.

5. Comfortable Feeding Height:

The feeding height of the mixer is ergonomically designed to allow operators to load materials comfortably without excessive bending or reaching, reducing the risk of strain injuries.

6. Easy to Move:

The 500kg castable refractory an mixer is equipped with wheels or a towing mechanism, allowing it to be easily relocated around the site as needed. This can save time and effort compared to stationary mixers that require materials to be brought to them.

7. With Bag Breaker:

A bag breaker feature allows for the easy opening and emptying of material bags directly into the mixer. This can help to minimize dust and spillage during the loading process.

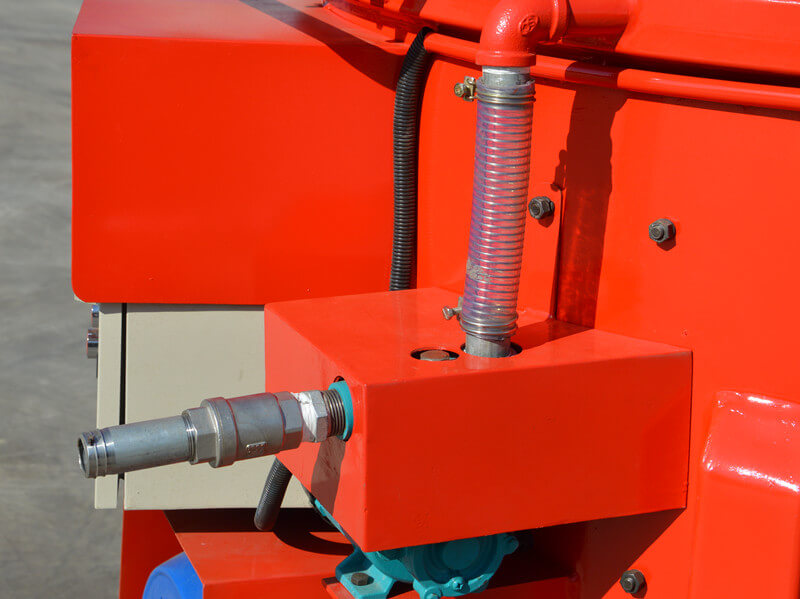

8. Water Spray Nozzles:

Integrated water spray nozzles provide precise control over the amount of water added to the mix, which is crucial for achieving the right consistency. They can also be used to clean the interior of the mixer after use.

9. Low Maintenance Cost:

The 500kg pan refractory concrete mixer is designed to require minimal maintenance, which can save on operational costs over time. This could mean fewer moving parts, easy access for servicing, and the use of durable materials that last longer.

► Package and Delivery Pictures:

|

Item |

LRM500 refractory concrete mixer |

||

|

Mixing capacity |

500kg |

||

|

Rotating speed |

36rpm |

||

|

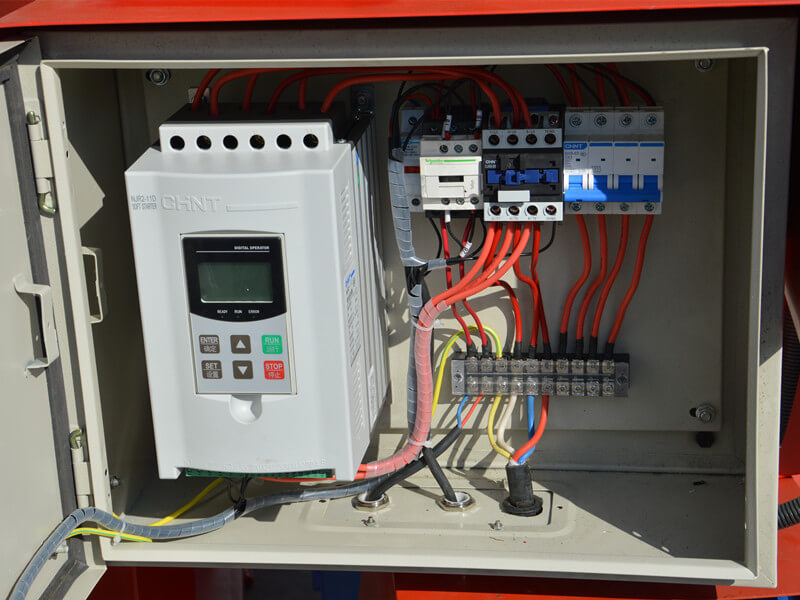

Motor power |

11kw |

||

|

Feeding height |

1300mm |

||

|

Dimensions (mm) |

1700x1250x1350mm |

||

|

Weight |

1010kg |

||

|

Note: |

|||

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS