►Description:

LRM100 100kg refractory castable mixer is industrial equipment specifically designed for mixing refractory materials, which typically withstand extremely high temperatures and chemical erosion. This mixer is extensively employed across various industries, including steel, cement, glass manufacturing, and petrochemicals, for the preparation of diverse refractory castables and spray coatings.

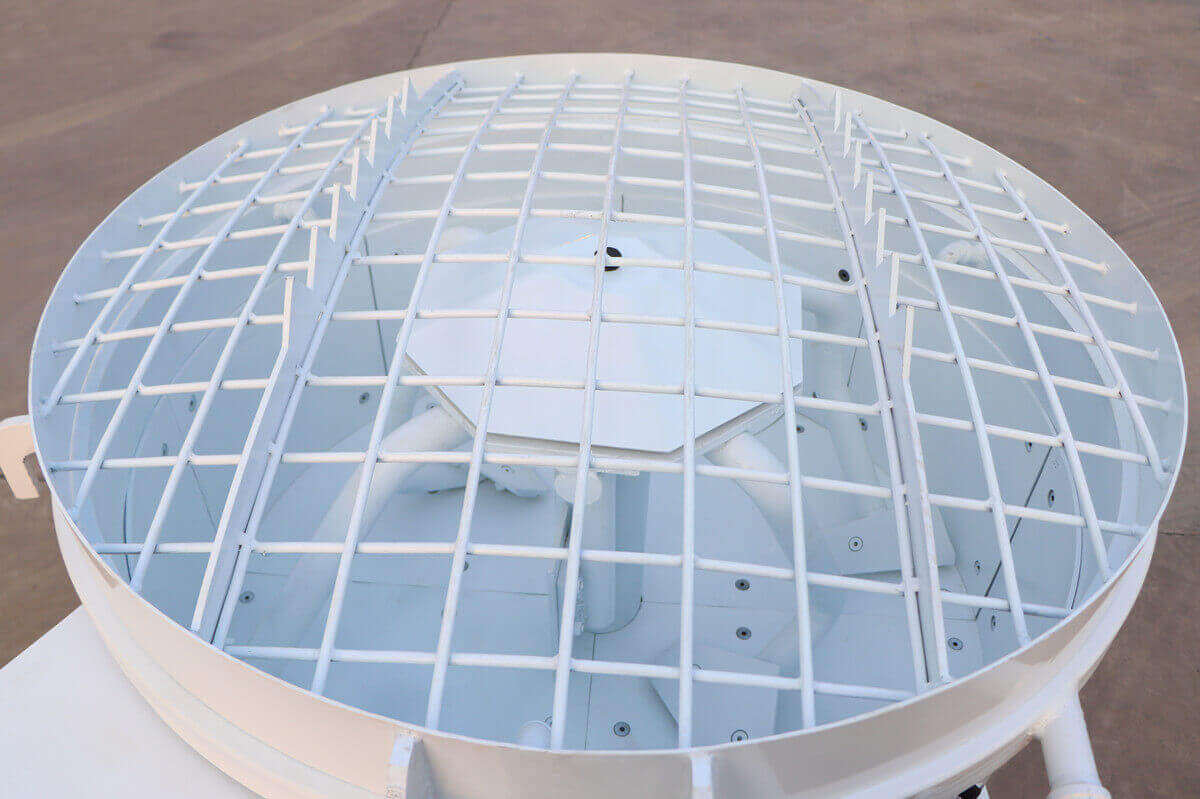

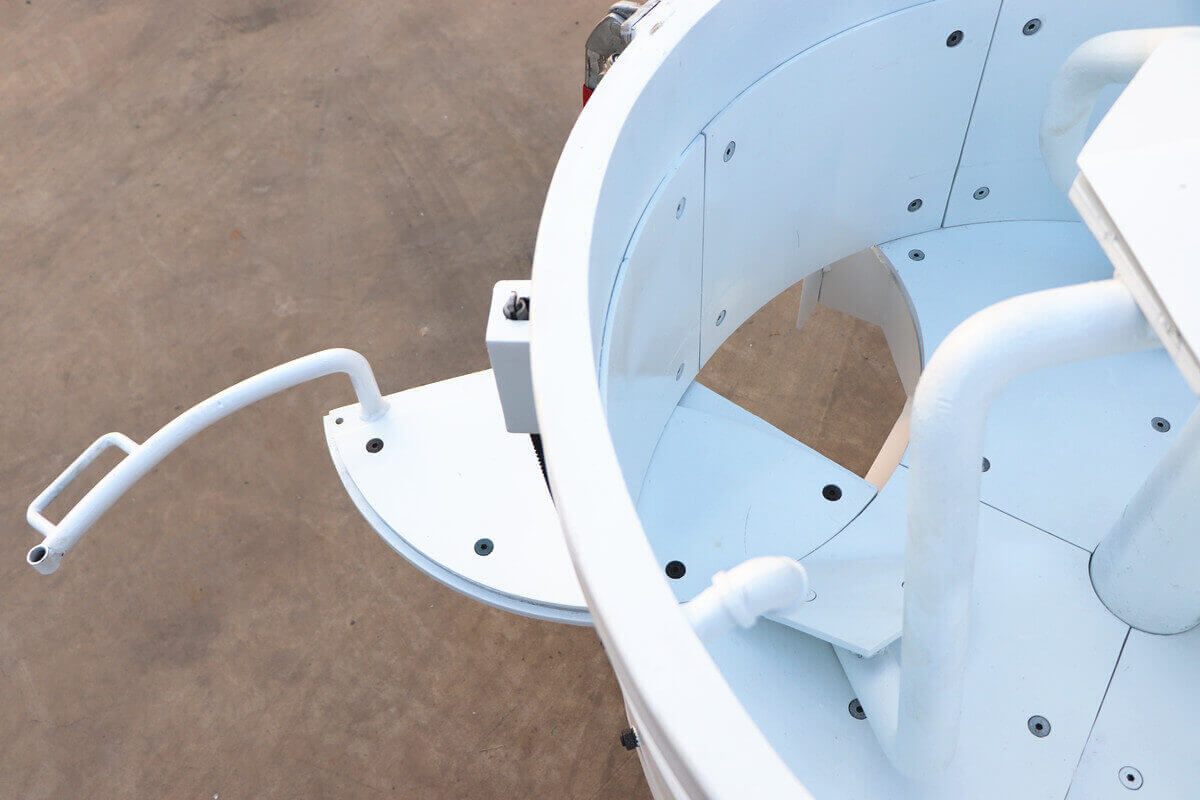

There is a high wear-resistant steel liner in the 100kg refractory castable mixer bottom and inner wall, five pieces of different purpose mixing arm could make refractory materials mix evenly and void sticking.

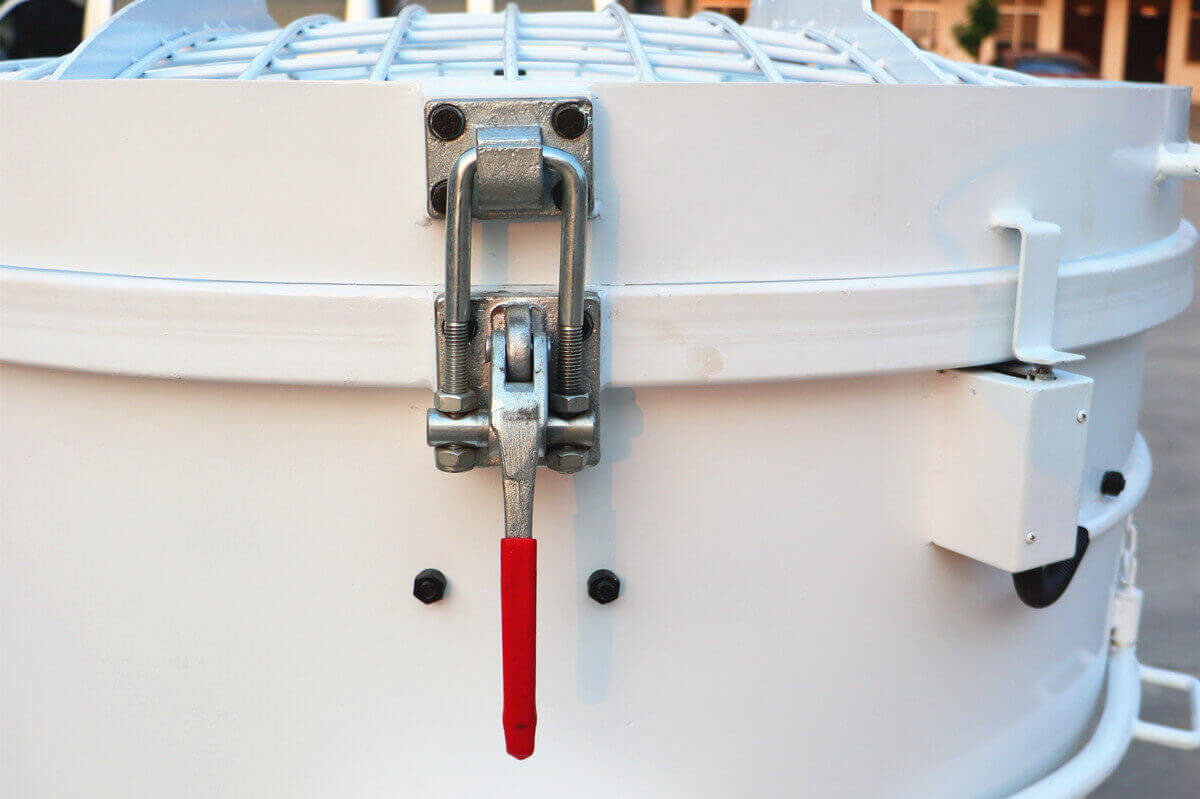

Safety feature of 100kg castable refractory mixer:

If the top lid door is opened in between the operations, the machine can stop automatically. Because there is a limit switch between the top lid door and the hopper, once the top lid is opened, the power will cut off automatically and confirm the safety of the operator.

►Application:

LRM100 100kg 100kg refractory castable pan mixer can handle both shaped refractory materials (such as fired products and non-fired products) and unshaped refractory materials (such as castables, spray coatings, ramming materials, and plastic materials, etc.).

Application areas of specialized 100kg refractory castable mixer:

1. Steel Industry: During steel production, extensive refractory materials are necessary to shield the furnace lining from molten metal and high temperatures. The refractory mixer is employed to blend raw materials such as high alumina bricks, magnesia carbon bricks, and silicon carbide bricks, to create refractory materials suitable for pouring, spraying, or ramming.

2. Building Materials Industry: In producing building materials, refractory materials are utilized for high-strength concrete, refractory bricks, and acid-resistant bricks, among others. Mixers assist in blending various types and specifications of raw materials to fulfill specific construction requirements.

3. Cement Industry: Refractory materials play a crucial role in the lining of cement kilns, which must withstand the high temperatures of cement clinker. Mixers are utilized to prepare refractory materials suitable for the cement industry.

4. Petrochemical Industry: In the petrochemical sector, equipment such as cracking and heating furnaces require refractory materials to endure high-temperature operating conditions. The refractory mixer ensures uniform mixing and optimal performance of these materials.

5. Ceramic and Glass Industry: During the manufacturing of ceramics and glass, refractory materials are employed to line kilns, safeguarding against high-temperature damage to the furnace structure. Mixers aid in the preparation of high-quality refractory materials.

6. Power Industry: Certain sections of boilers and power plants, like the combustion chambers of coal-fired boilers, require refractory materials for thermal insulation against high temperatures.

7. Nonferrous Metal Smelting: The smelting processes of nonferrous metals, such as copper and aluminum, similarly depend on refractory materials to shield equipment from molten metal corrosion.

► Features:

★ 100kg refractory pan mixer is special designed for site operation;

★ Fast mixing speed and homogenous;

★ Easy to move;

★ Compact structure;

★ 100kg castable pan mixper;

★ Comfortable feeding height;

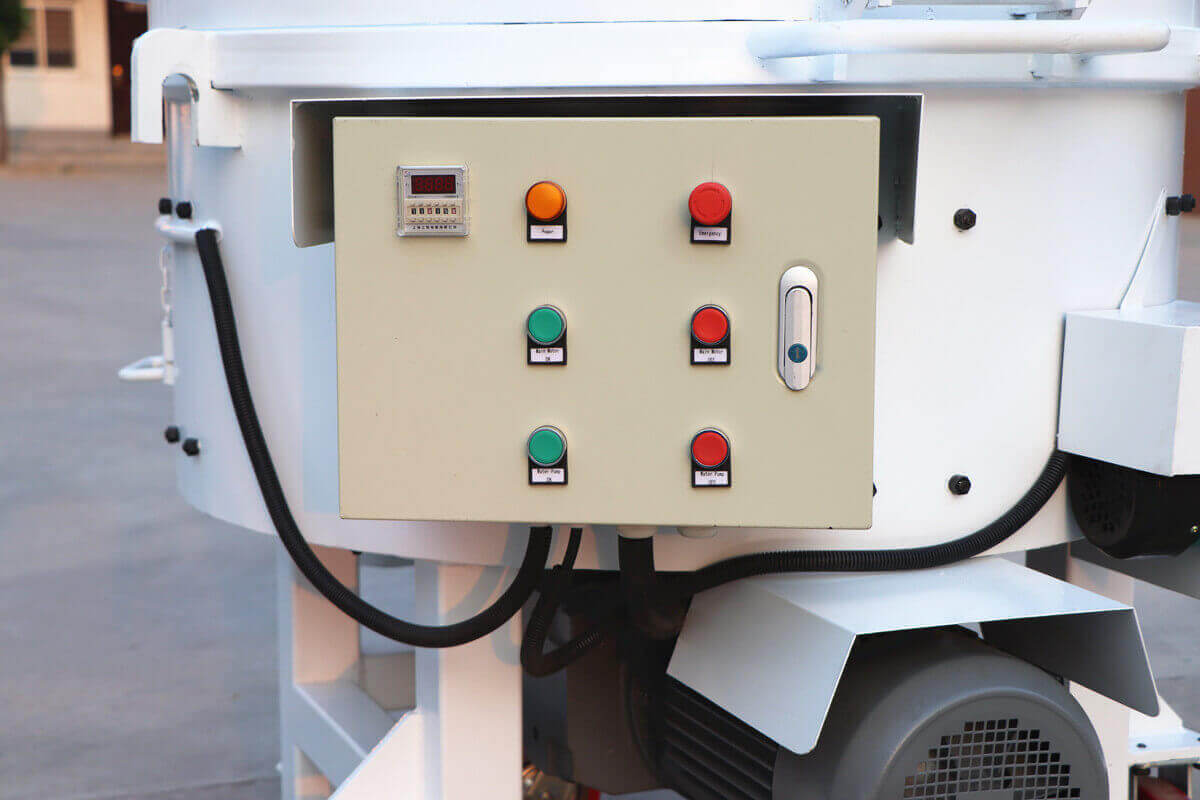

★ Water spray nozzles;

★ With bag breaker;

★ Low maintenance cost.

|

Item |

LRM100 100kg refractory castable mixer |

||

|

Mixing capacity |

100kg |

||

|

Rotating speed |

33rpm |

||

|

Motor power |

4kw |

||

|

Feeding height |

1100mm |

||

|

Dimensions (mm) |

1400x1300x1100 |

||

|

Weight |

550kg |

||

|

Note: Technical data may change due to technical progress, subject to modification without notice. |

|||

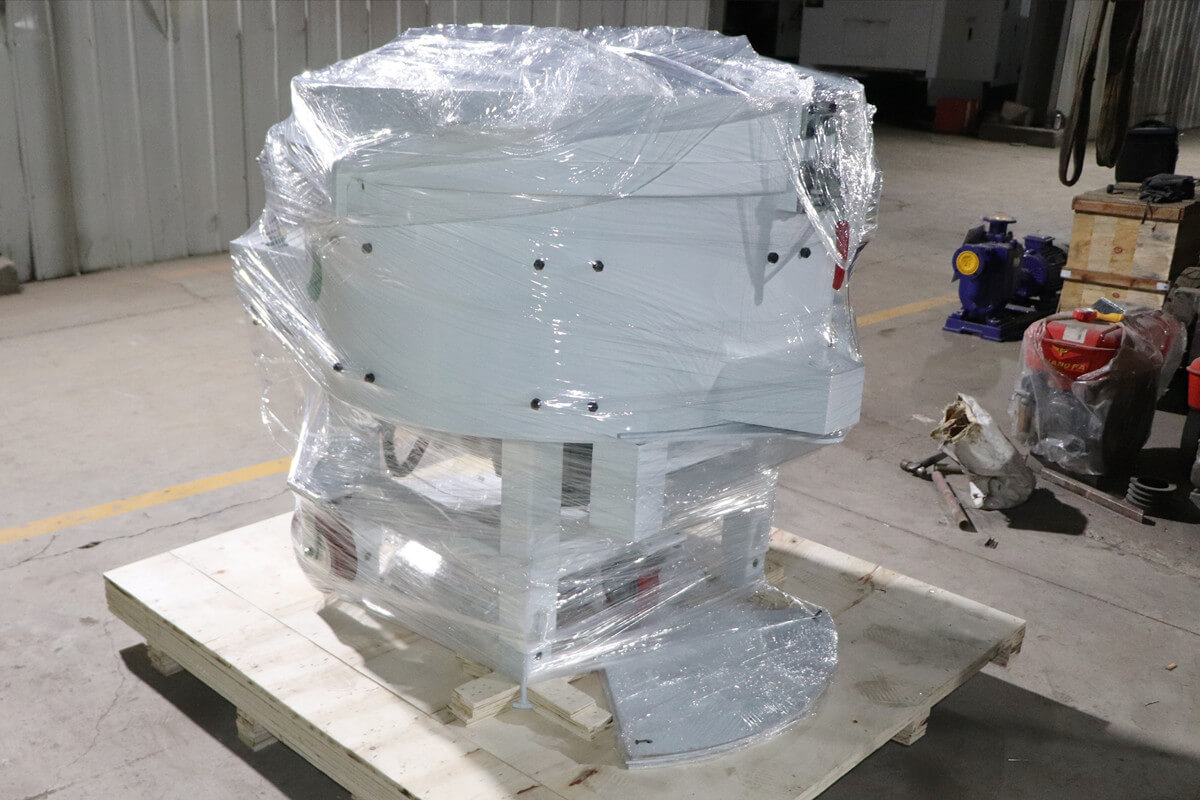

LRM100 100kg refractory castable mixer packing and delivery pictures:

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS