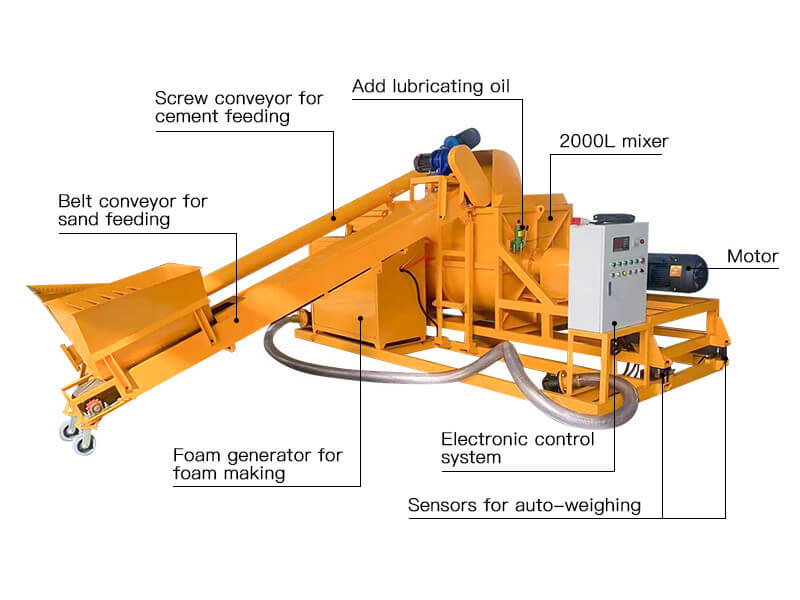

The LM2000 CLC cellular lightweight concrete mixer is designed with several key components: the feeding mechanism which utilizes screw and belt conveyors, the foaming system that features a foam generator, the mixing component that includes a specialized foam concrete mixer, the control system with an integrated control panel, and the weighing system that employs load cells.

► Application:

The LM2000 CLC cellular lightweight concrete mixer is utilized to blend cement, sand, water, foam, and other raw materials into a fluid form of foam concrete.

The resulting foam concrete can then be applied in various construction scenarios such as floor heating systems, roof insulation, cellular lightweight concrete (CLC) blocks, cast-in-place walls, foundation fillings, tunnel fillings, and more.

► Features:

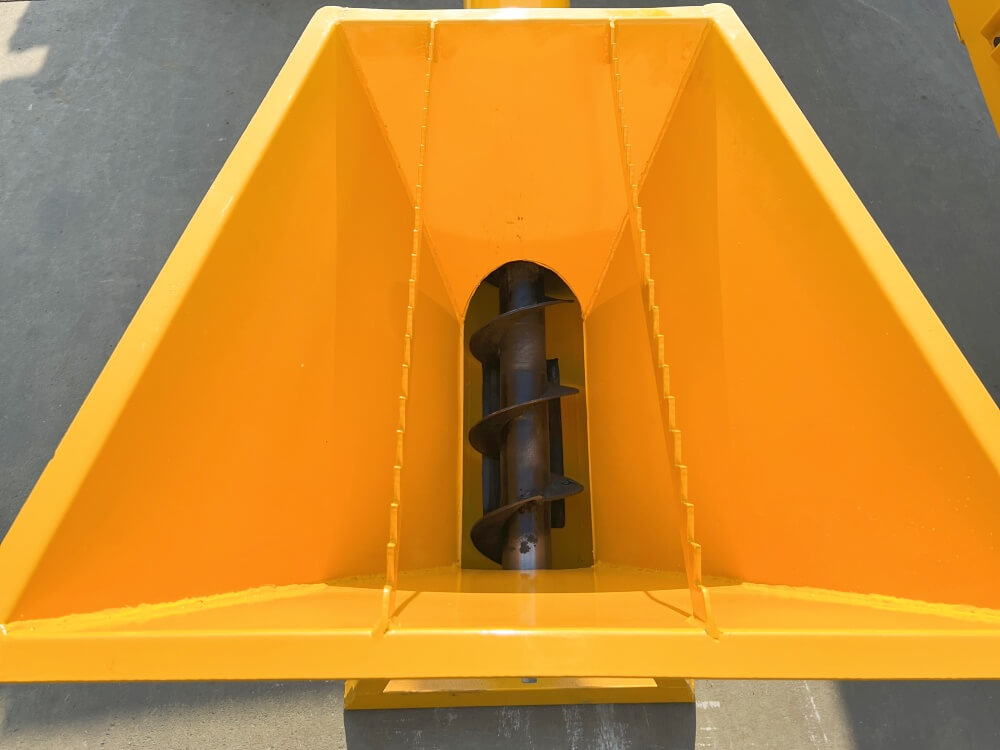

1. Feeding System: Utilizes a screw conveyor for cement and a belt conveyor for sand, ensuring efficient and controlled material delivery.

2. Auto-Weighing System: Automatically measures each material, saving both time and labor, and ensuring precise proportions.

3. Mixer System: Features a large capacity of 2000 liters per batch, enhancing productivity and efficiency.

4. Foam Addition: Incorporates foam directly into the mixer, ensuring that the foam concrete is mixed evenly throughout.

5. Lubrication System: Maintains optimal machine performance and durability through regular lubrication.

6. Control System: Offers centralized control for ease of operation and management.

► CLC foam concrete production line factory display:

| Model | LM2000 CLC cellular lightweight concrete mixer |

| Capacity | 20-30m3/h |

| Power | 30Kw |

| Voltage | 3 phase, 380V, 50Hz |

| Mixer volume | 2000L |

| Water pump | 50m3/h |

| Foam generator | 30m3/h |

| Measurement method | Cumulative measurement |

| Discharge method | Manual discharge |

| Belt conveyor | 300*3800mm |

| Screw conveyor | φ165*4000mm |

| Main part dimension | 4000*2050*1900mm |

| Weight | 1500kg |

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS