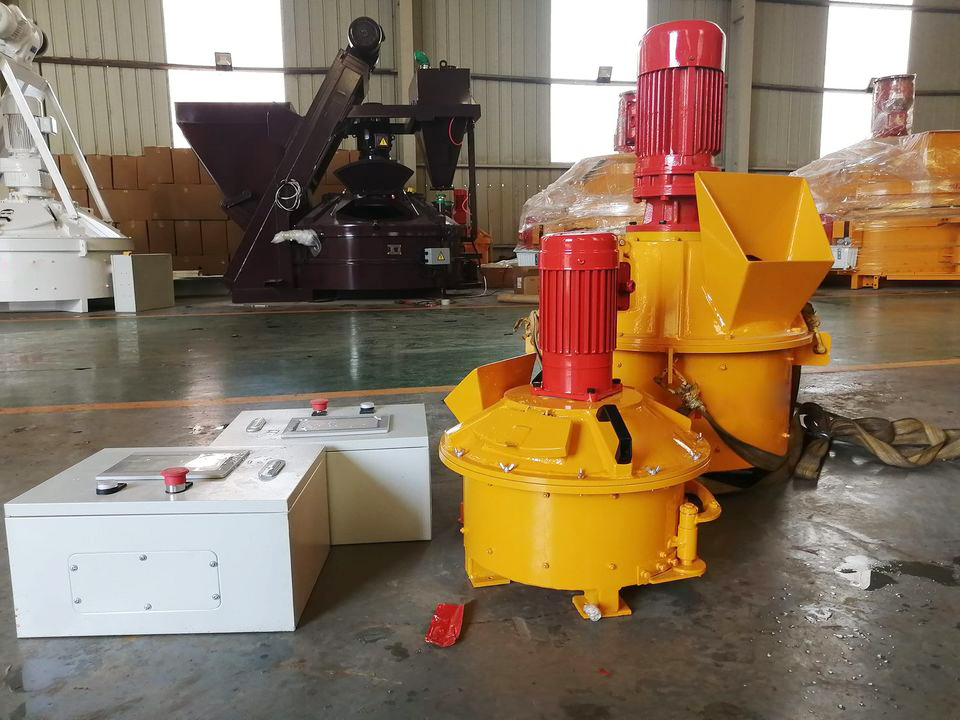

Vertical shaft planetary mortar mixer

The specially developed gearbox (patented technology) can effectively distribute the power balance to each mixing device, and the vertical shaft planetary mortar mixer can ensure efficient and low-noise operation even under harsh production conditions. While saving space, the maintenance space of the mixer is increased by 30% compared with the traditional gearbox.

The Vertical shaft planetary mortar mixer can quickly mix all kinds of high-quality concrete (dry, semi dry and plastic). The versatility of the mixer makes it not only used for concrete production, but also used for the mixing of glass, ceramics, refractories and other materials.

The gearbox unit (patented technology) is specially designed for the power balance distribution of various mixing devices, which can ensure low noise and gapless rotation even under harsh working conditions. Compared with the traditional gearbox, the unit occupies less space and the maintenance space of the mixer can be expanded by 30%.

Vertical shaft planetary mortar mixer is equipped with mechanical coupling and hydraulic coupling (optional), which can protect the transmission device from overload and impact.

Nickel hard cast iron blade is more wear-resistant. As an alternative, we also provide polyurethane blades that meet special requirements. Depending on the material, the liner and ceramic tile can be cast iron, HARDOX steel plate (original Swedish) or hard faced material.

From model selection to customized mixers for special applications, we can also provide all-round technical support and maintenance services.