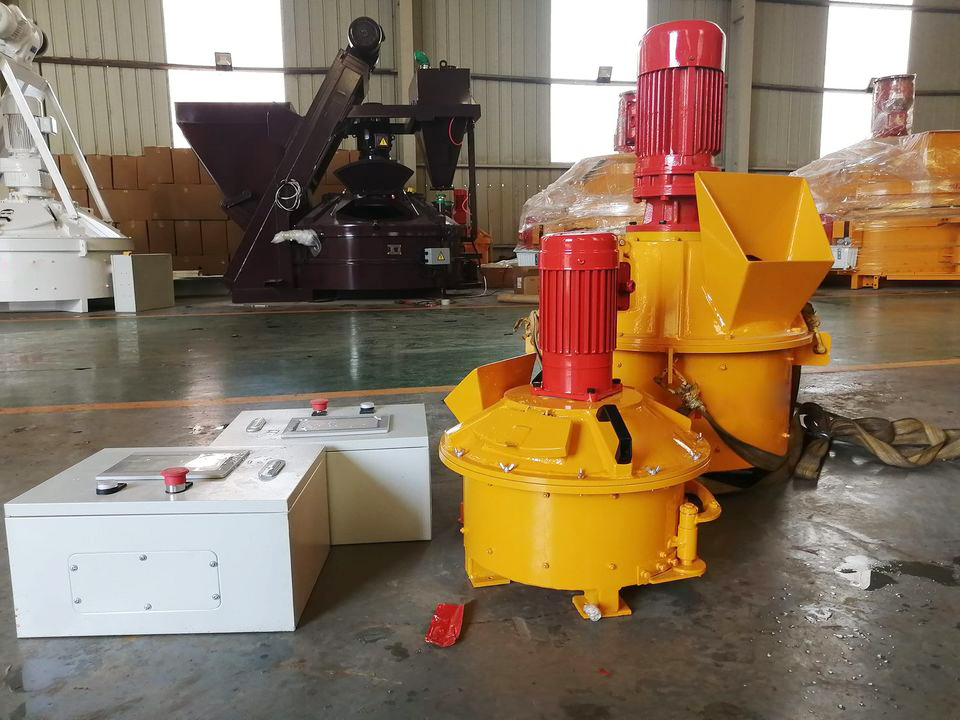

vertical shaft mixers for UHPC Ultra-High Performance Concrete

The vertical shaft mixers for UHPC Ultra-High Performance Concrete has an advanced stirring device, and the planetary operation feature prevents the equipment from holding the shaft during use; the vertical shaft planetary mixer has an excellent water supply system.

The vertical shaft mixers for UHPC Ultra-High Performance Concrete adopt a planetary operation device to ensure the quality and stability of the mixing operation. The hardened surface reducer and the mixing device lay the equipment foundation for the equipment’s advantages. The vertical shaft planetary mixer has stable operation, low noise, and reliable mixing quality, whether it is stirring at high speed or low speed.

The mixing trajectory of the vertical shaft mixers for UHPC Ultra-High Performance Concrete is the compound motion of the superposition of revolution and rotation and is designed in a non-circulating mode. The stirring planet can completely cover the bottom of the stirring tank every 5 seconds, and there is no stirring dead angle. According to the different requirements of customers’ materials, the mixing device can be individually customized and designed.

The revolution and rotation of the stirring blade of the vertical axis planetary mixer are determined by in-depth research and continuous testing so that the mixer can achieve greater productivity without segregation of aggregates of various particle sizes and specific gravity.