Home » Planetary concrete mixer » vertical shaft concrete mixer for fertilizer

vertical shaft concrete mixer for fertilizer

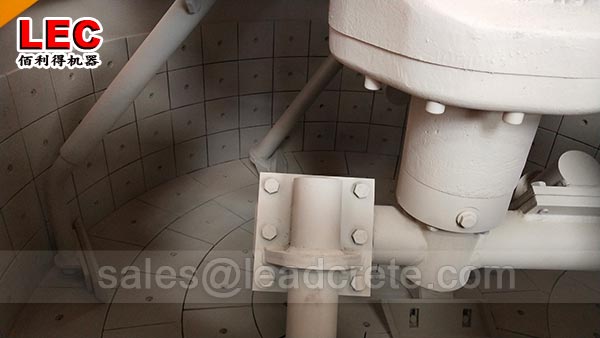

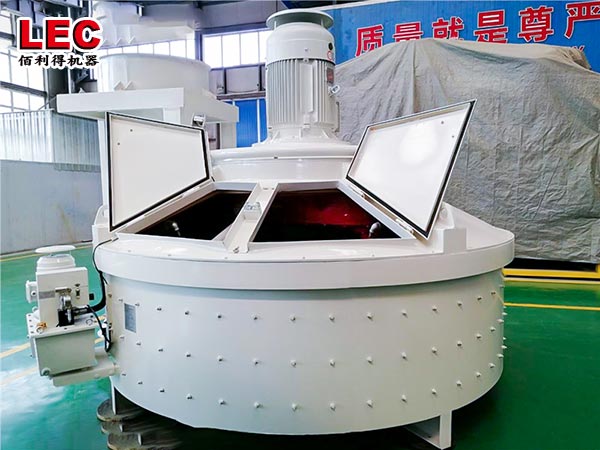

A vertical shaft concrete mixer for fertilizer has high-quality and continuous treatment efficiency and can form high-quality treatment forms under various production and treatment conditions. within the control range.

Contact Us

Get Price

Share:

Content 2022-04-21

The vertical shaft concrete mixer for fertilizer has flexible mixing uniformity, and the mixing speed of the equipment can realize step-less speed regulation within a wide range, maintain a reliable and stable transmission, improve the operating efficiency of the mixer, reduce the energy consumption of the equipment, and ensure that the mixer works without noise.

Inquiry

More Planetary concrete mixer