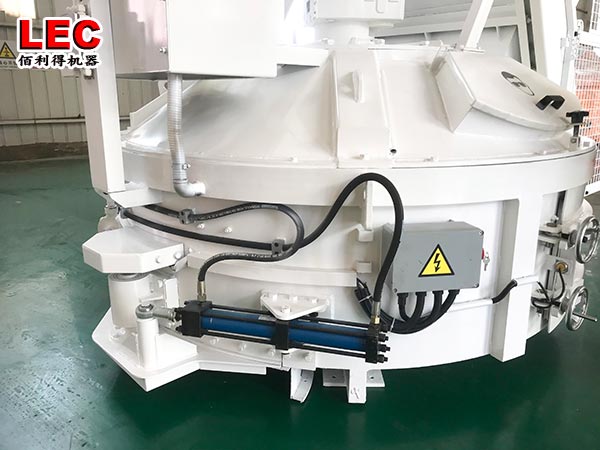

Vertical planetary mixer

Vertical planetary mixer is permeable to water and has good air permeability. In the rainy season, rainwater can be quickly infiltrated into the ground to maintain soil moisture and improve the ecological balance of the surface.

The mixer adopts vertical planetary mixer.

Its advantages: stable transmission, compact structure, novel style, excellent performance, economical and durable, convenient installation and maintenance, no leakage problems, the main electrical components are Schneider or Siemens brands.

The advantages of vertical planetary mixer:

Excellent mixing performance, accurate and stable measurement, high reliability, easy maintenance, good environmental performance, energy saving and low power consumption Leadcrete will customize high-end production lines according to each customer’s production requirements and provide 24H technical service support.