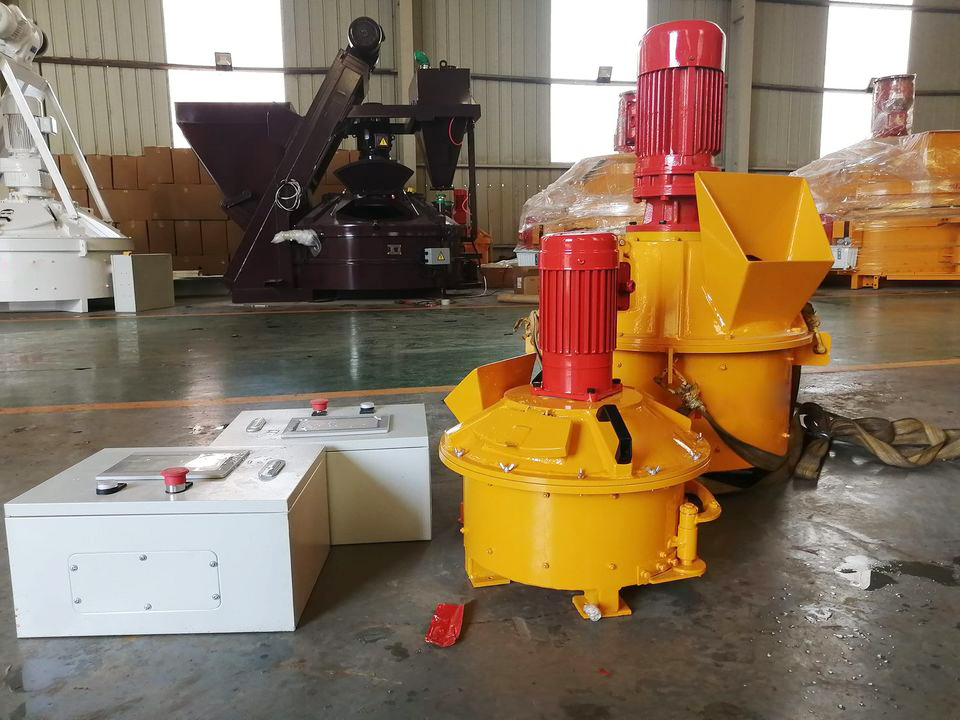

UHPC planetary concrete mixer factory

There are many factories that produce UHPC planetary concrete mixers, Leadcrete Equipment is one of the most popular factories, our products have been used in various construction and engineering projects around the world.

The scrapers on the planetary carrier of the planetary vertical shaft mixer supplied by the UHPC planetary concrete mixer factory rotate with the planetary carrier. By constantly scraping the wall of the cylinder, the material on the wall of the cylinder is brought back into the cylinder to ensure that there is no residue on the wall of the cylinder, and the mixing degree of the material is greatly improved. The planetary vertical shaft mixer is more suitable for the layout of the production line in the concrete industry than the concrete mixer of the same volume.

Diverse effects of planetary concrete mixer:

1. Planetary multi-level refined forced mixing effectively protects the original form of the mixed material.

2. The fully automatic operation of the planetary concrete mixer contributes to the improvement of energy conversion rate and energy saving effect.

3. Stir to form three-dimensional mixing, no dead angle in mixing, high uniformity, fast mixing speed, and fast and clean discharge.

The unique mixing device of the planetary mixer provided by the UHPC planetary concrete mixer factory enables the material to achieve omnidirectional, 360-degree, high-uniformity mixing without dead ends during the mixing process. The strong stirring force generated by the stirring blade installed on the shaft of the planetary mixer greatly promotes the two-way movement of the material in the axial and radial directions and achieves highly uniform mixing through the vigorous and sufficient stirring of the material.

The planetary mixer cylinder and mixing blades are finely processed, and the blades and lining are made of wear-resistant materials. As a special model for curbstone production, the planetary mixer uses the principle of planetary mixing to greatly speed up the mixing speed of materials. Multi-stage mixing strengthens the mechanical mixing ability of the equipment in the whole production and processing process and greatly improves the mixing efficiency of the industry.