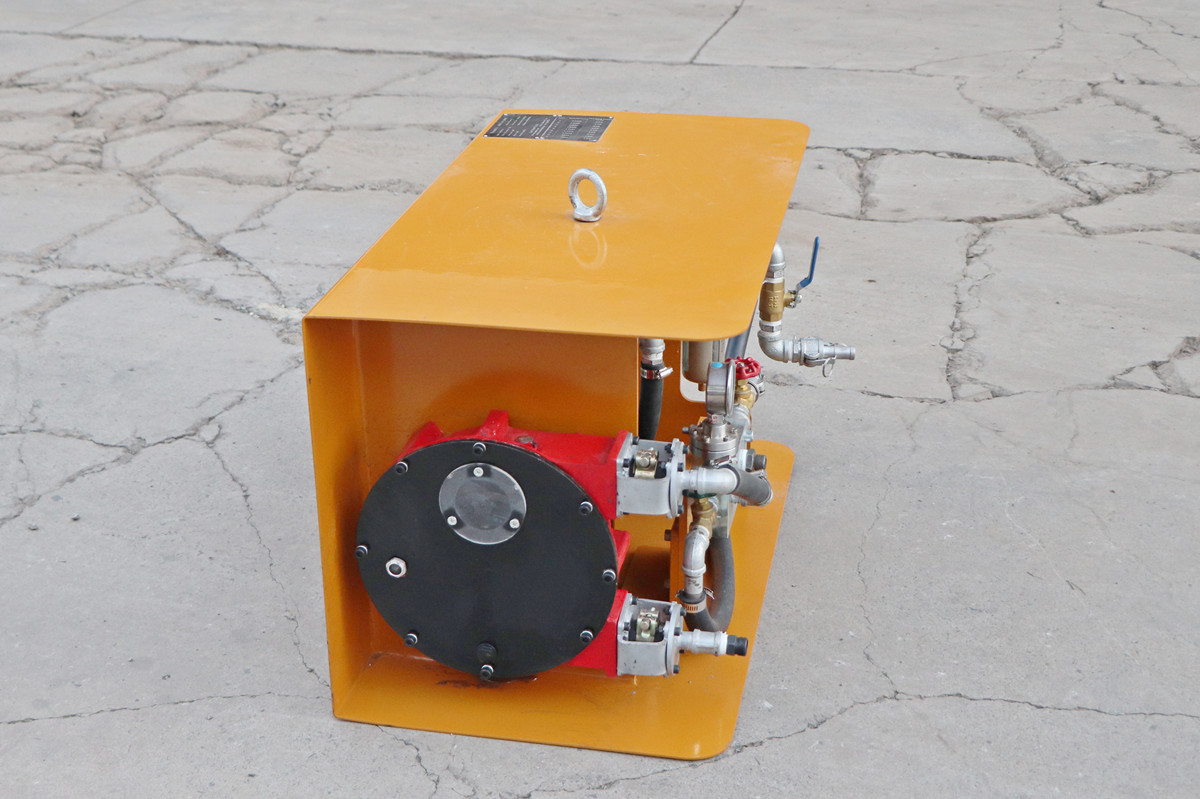

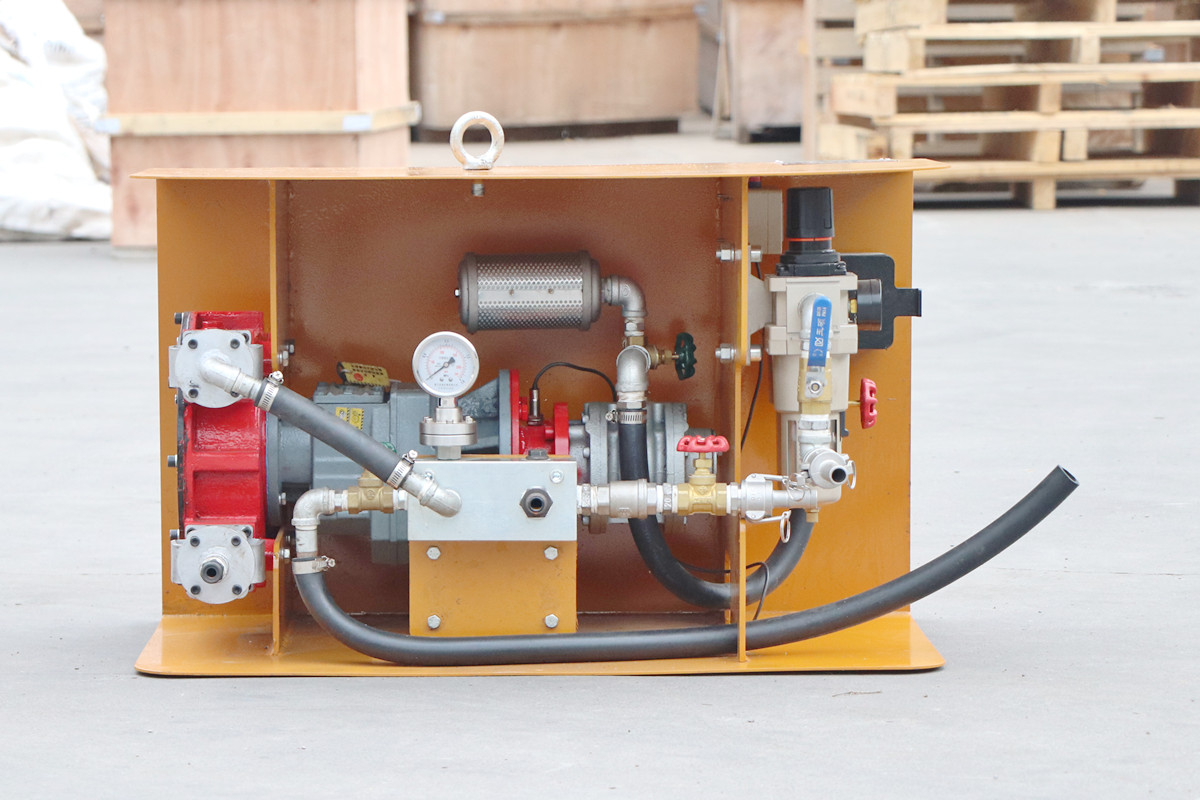

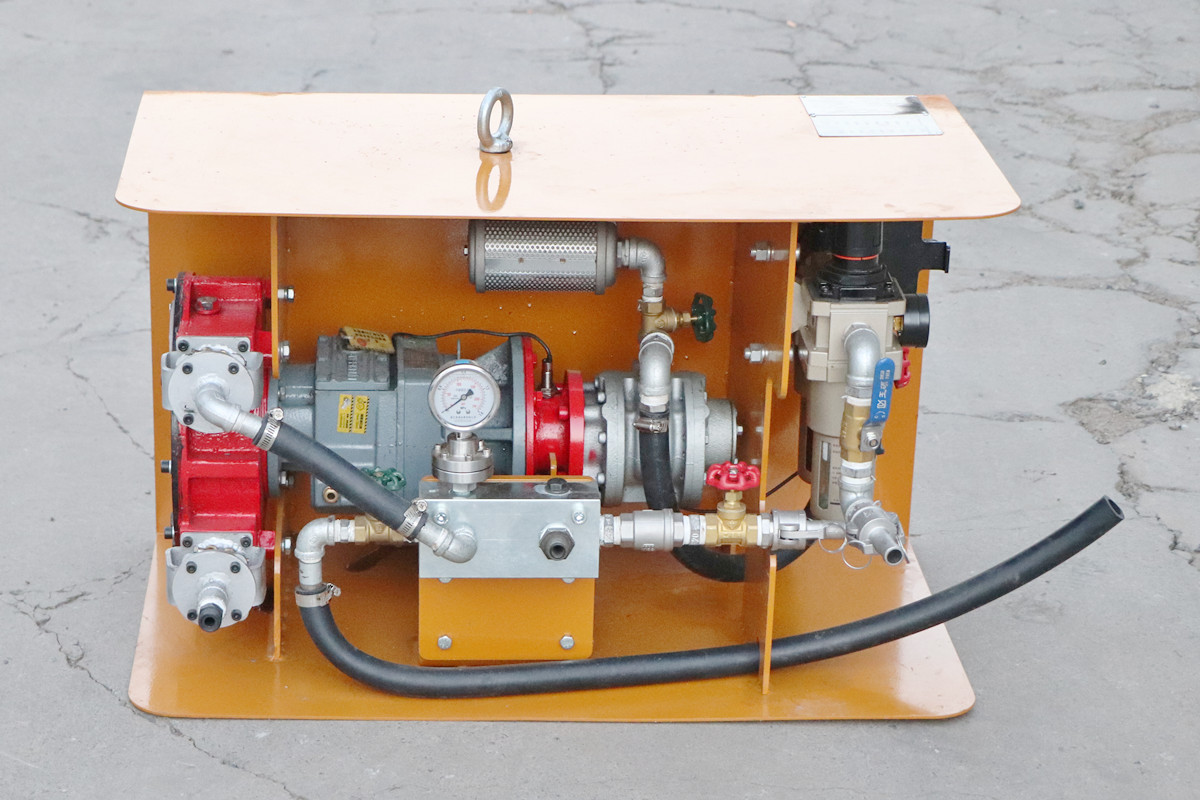

Small wet mix shotcrete machine

Small wet shotcrete machines are not directly used in fiber-reinforced dry shotcrete mixture projects. However, in situations where wet shotcrete is required, small wet shotcrete machines are still an efficient and reliable choice. For fiber-reinforced dry shotcrete mixture projects, it is necessary to select shotcrete equipment that is specifically suitable for dry shotcrete and has fiber reinforcement functions. In practical applications, the appropriate shotcrete equipment and process should be selected according to specific engineering requirements and material properties.

There are some differences in material handling methods and application scenarios between small wet mix shotcrete machine and fiber reinforced dry-mix shotcrete mixture projects. Generally, small wet mix shotcrete machine is mainly used for wet shotcrete operations, while fiber reinforced dry-mix shotcrete mixture focuses more on dry spraying and adds fiber reinforcement.

Features and Applications of Small Wet Mix Shotcrete Machine

Features:

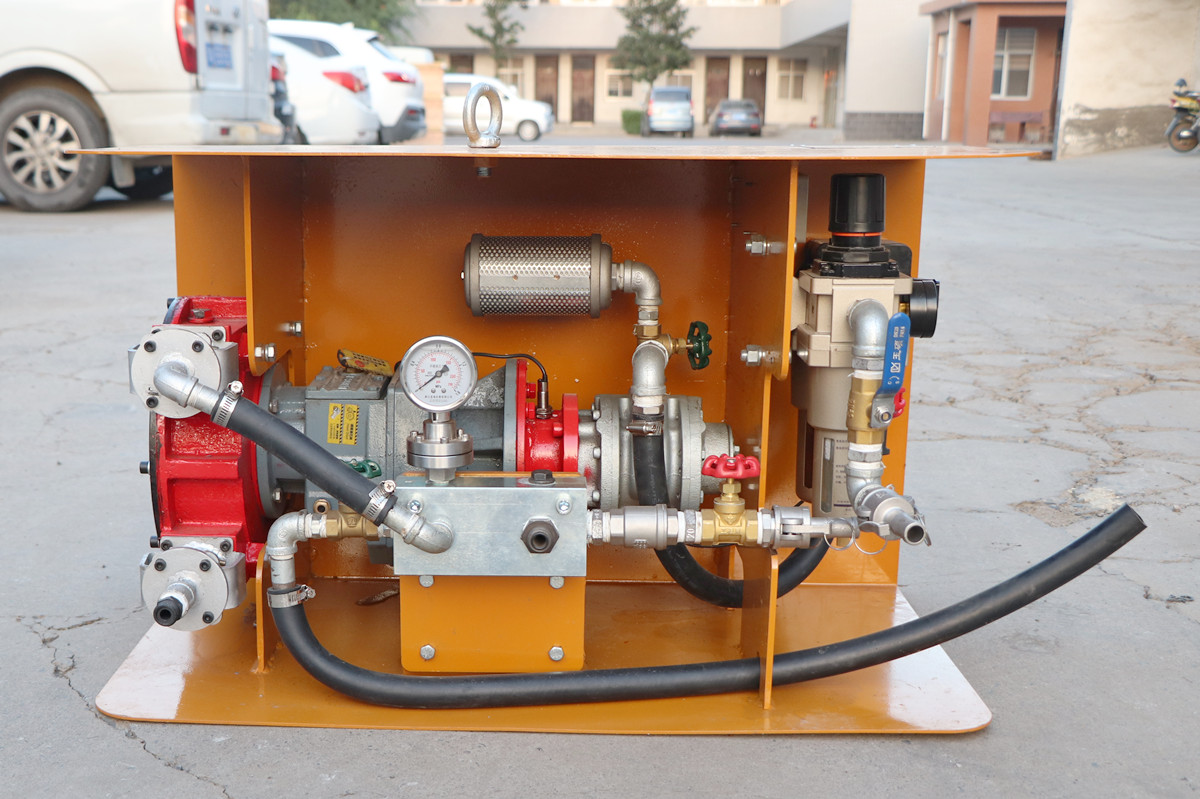

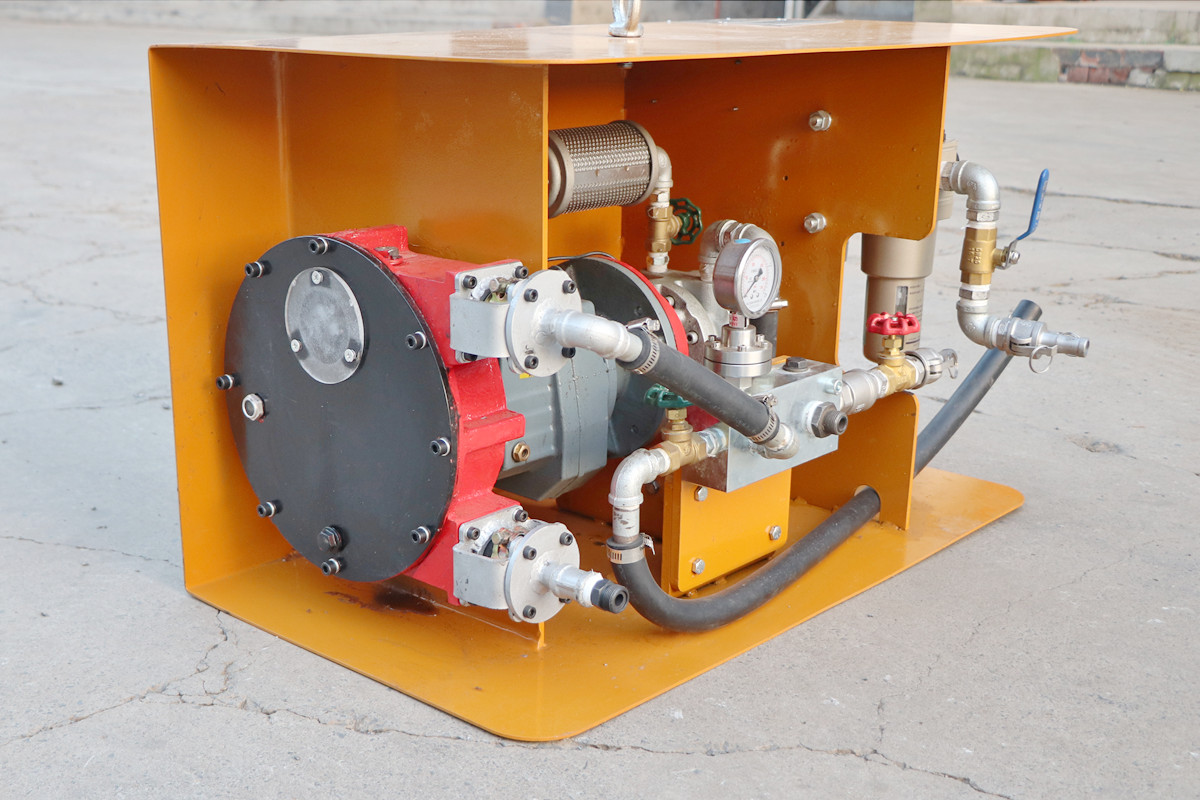

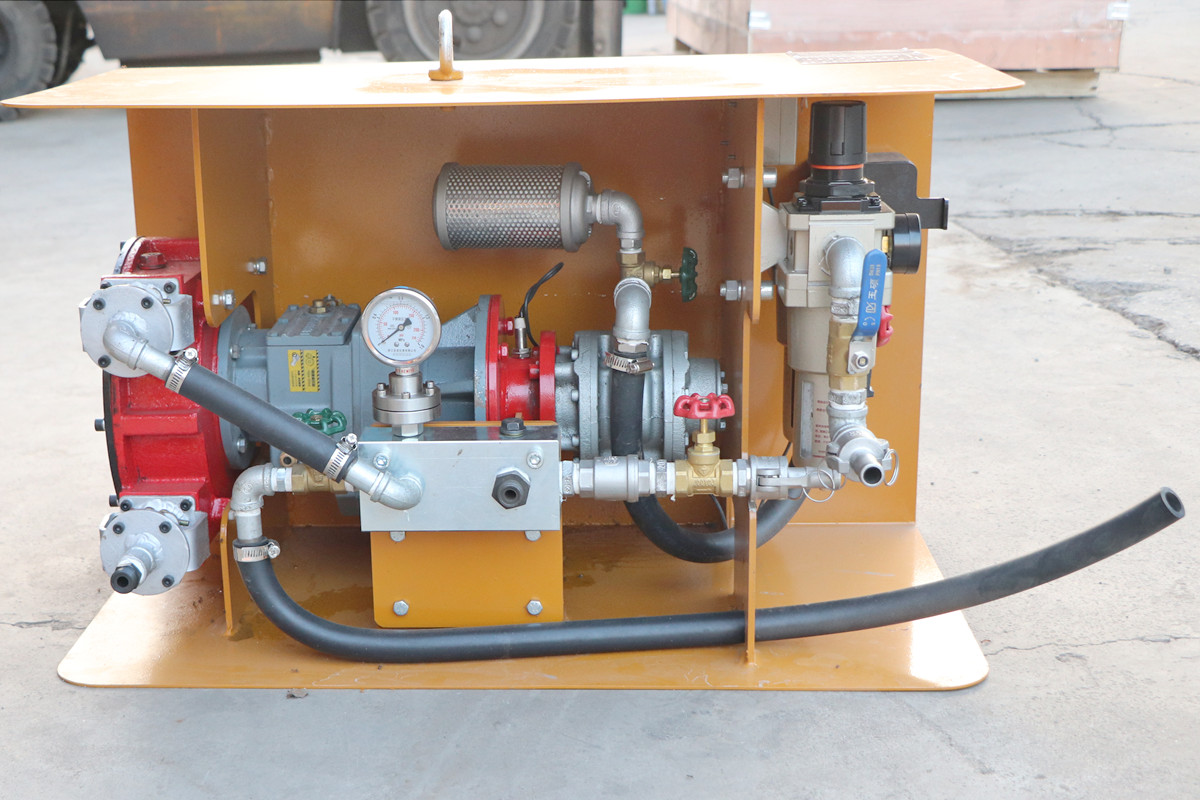

Wet spraying: using pre-mixed and watered concrete for spraying.

High efficiency: Ability to spray concrete continuously and evenly.

Wide applicability: Suitable for various concrete spraying operations, such as tunnels, mines, underground projects, etc.

Applications:

Small wet mix shotcrete machine performs well in situations where wet shotcrete is required, such as tunnel lining, slope reinforcement, etc.

Due to its small size and easy operation, it is also suitable for narrow or difficult-to-access areas.

Characteristics and Applications of Fiber-Reinforced Dry Shotcrete Mixtures

Characteristics:

Dry spraying: Using pre-mixed dry concrete materials, concrete is sprayed onto the target surface through compressed air.

Fiber reinforcement: Adding fiber materials to concrete to improve the tensile strength and durability of concrete.

Flexibility: The type and content of fibers can be adjusted according to specific engineering needs.

Applications:

Fiber-reinforced dry shotcrete mixtures are often used in situations where high strength and durability are required, such as bridges, tunnels, and building exterior walls.

The addition of fibers can also improve the crack resistance and impermeability of concrete, and is suitable for structures that need to withstand loads and harsh environments for a long time.

Differences between the two

Material processing methods: Small wet shotcrete machines use wet spraying, while fiber-reinforced dry shotcrete mixtures use dry spraying.

Application scenarios: Although both can be used for concrete spraying operations, small wet shotcrete machines are more suitable for situations where wet spraying is required, while fiber-reinforced dry shotcrete mixtures focus more on structures that require high strength and durability.

Material composition: Fiber materials are added to the fiber-reinforced dry shotcrete mixture to improve the mechanical properties of concrete, while small wet shotcrete machines mainly use ordinary wet concrete materials.