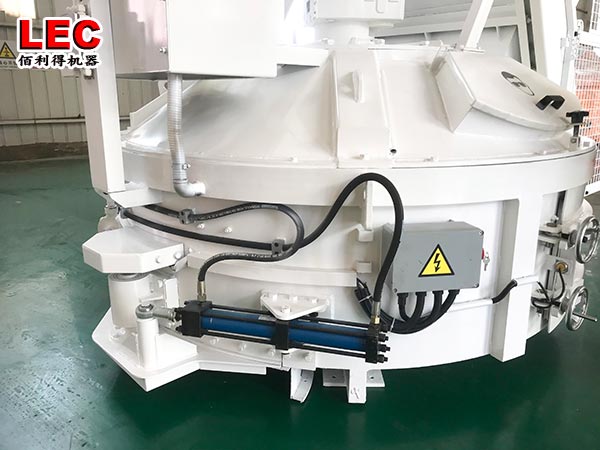

Small portable planetary concrete mixer

industries, the corresponding functions are continuously expanded on the basis of the basic functions of Small portable planetary concrete mixer, and the mixer equipment is deployed according to the specific application environment and standard.

The small portable planetary concrete mixer mixing arm pushes the front material forward; the agitated material is subjected to centrifugal force to perform circumferential circulation and convection motion; during this period, materials will also be used. Relative extrusion and shearing are generated, and the force is also turned upward under this force; the material behind the stirring arm of the planetary vertical shaft mixer replenishes the gap left by the front material, and the material is moved downward by gravity. This mix has both horizontal and vertical motion.

The small portable planetary concrete mixer solves the problem of uniformity of mixing of the twin-shaft concrete mixer.