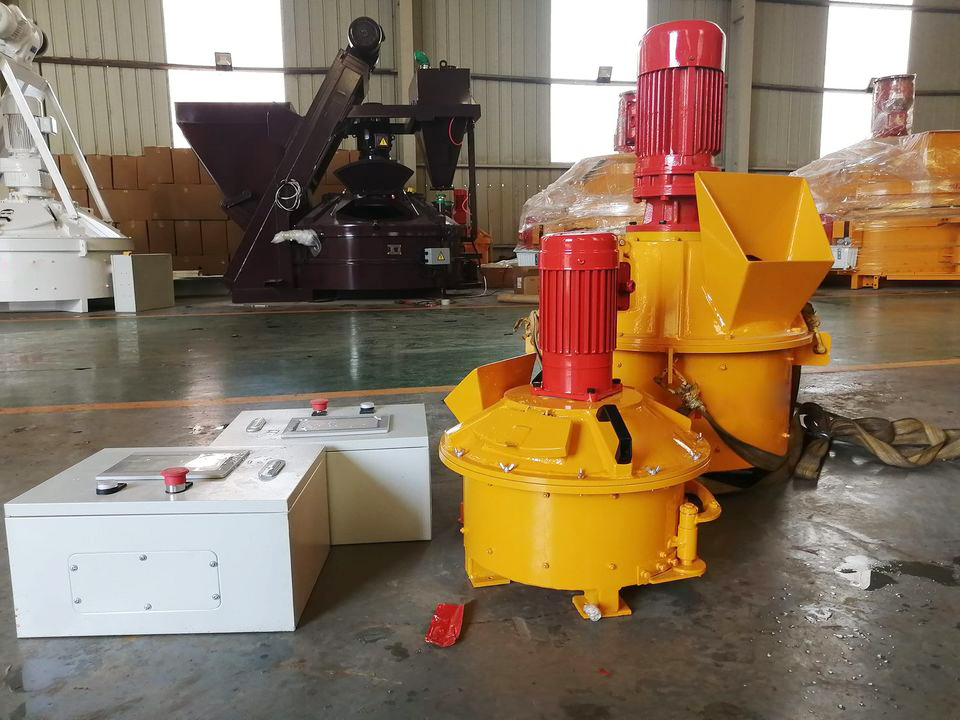

Sand and cement planetary mixer

Sand and cement planetary mixer uses a multi-group planetary running agitation tool to eliminate the agitation dead angle by the agitation mode formed by these mixing tools to prevent the agitation inefficient zone.

We recommend the sand and cement planetary mixer driven by a single motor. This type of sand and cement planetary mixer can guarantee the consumption of all the agitating planets. Can release the average, there will be no difference, and the consistency of the mixing quality is guaranteed.

Sand and cement planetary mixer is gear type, the more the precision transmission effect is more stable, the mixing precision will be very high, but there are certain requirements for production technology, so we need to compare the products of different manufacturers and choose a reliable refractory mixer.