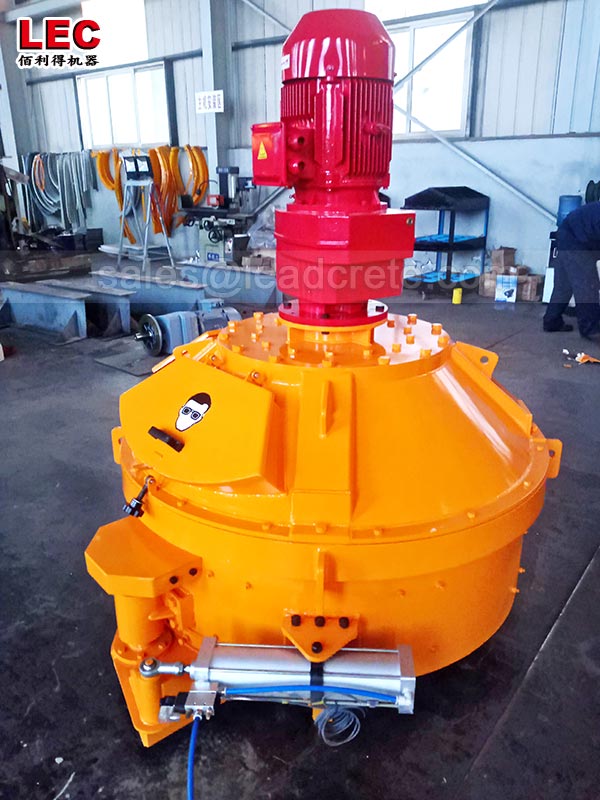

Ready-mix precast concrete mixer

With such a strong and bulky frame, the multi-star mixing action of the ready-mix precast concrete mixer provides fast, complete mixing of full-size batches. As an added bonus, the intense mixing action provided by planetary mixers will save you money on cement.

Versatility is key to efficient operations. With the line ready-mix precast concrete mixer, you can also process high-density materials other than concrete. The ready-mix precast concrete mixers are so powerful that they can start mixing with the entire batch of material, each planetary mixer is equipped with high-quality seals to prevent leakage of material. For simple and easy cleaning, the inspection port is designed with large openings to provide spacious maintenance access.

This is an essential feature for any operation that produces multiple color mixes in a day, allowing you to clean up before mixing the next batch. This will save you a lot of time, money and materials. The ready-mix precast concrete mixer uses one to three mixing stars, depending on the size of the mixer you need. Each mixing arm rotates around a central axis, and each blade rotates individually.