Professional manufacturer machine for concrete mixing

The mixing arm of the professional manufacturer machine for concrete mixing adopts a clip-type structure design to improve the utilization rate of the blade as much as possible.

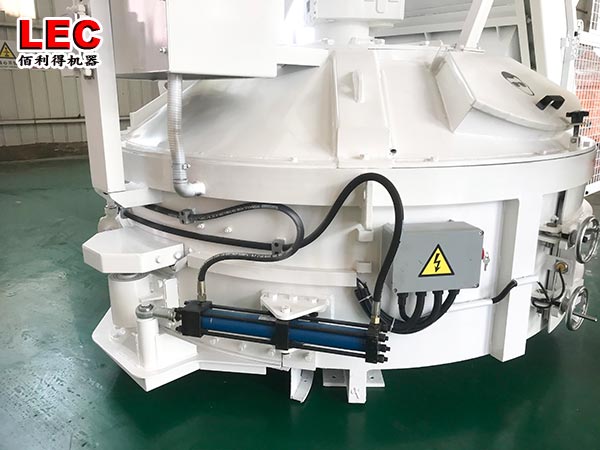

The overall quality of the mixed materials is good. The overall design of theprofessional manufacturer machine for concrete mixing meets the homogenization requirements, with compact structure, convenient operation, rapid discharge, sturdiness and durability, stable operation, and can be flexibly arranged in various production lines.

Meet environmental protection requirements. The professional manufacturer machine for concrete mixing adopts an effective sealing device with good sealing performance and no slurry leakage problem. The machine avoids waste of energy and reduces pollution emissions during use, which is very beneficial to environmental protection.