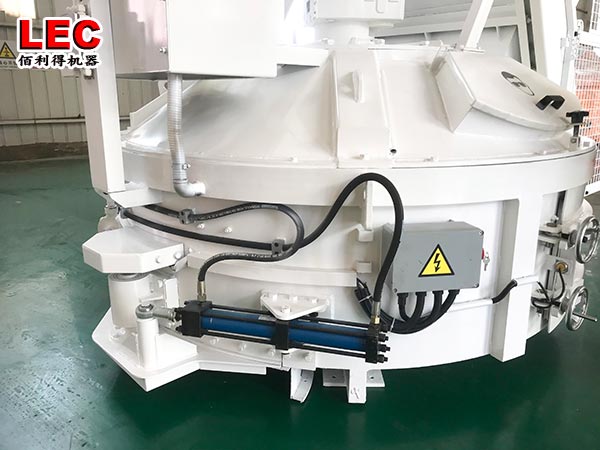

Professional castable pan mixer refractory manufacturer

We are professional castable pan mixer refractory manufacturer factory and supplier, any need this machine you can tell me freely.

Professional castable pan mixer refractory manufacturer can meet the mixing requirements of various materials. For various types of materials, the planetary concrete mixer can meet the mixing requirements. The appropriate speed and strength can be selected according to the nature of the material to ensure that the original form High degree of automation. The professional refractory castable pan mixer uses computer integrated operation, which can save labor. The work of the machine promotes the movement of the material in the cylinder, and the material moves in the planetary motion in the cylinder, and the mixing uniformity is high.