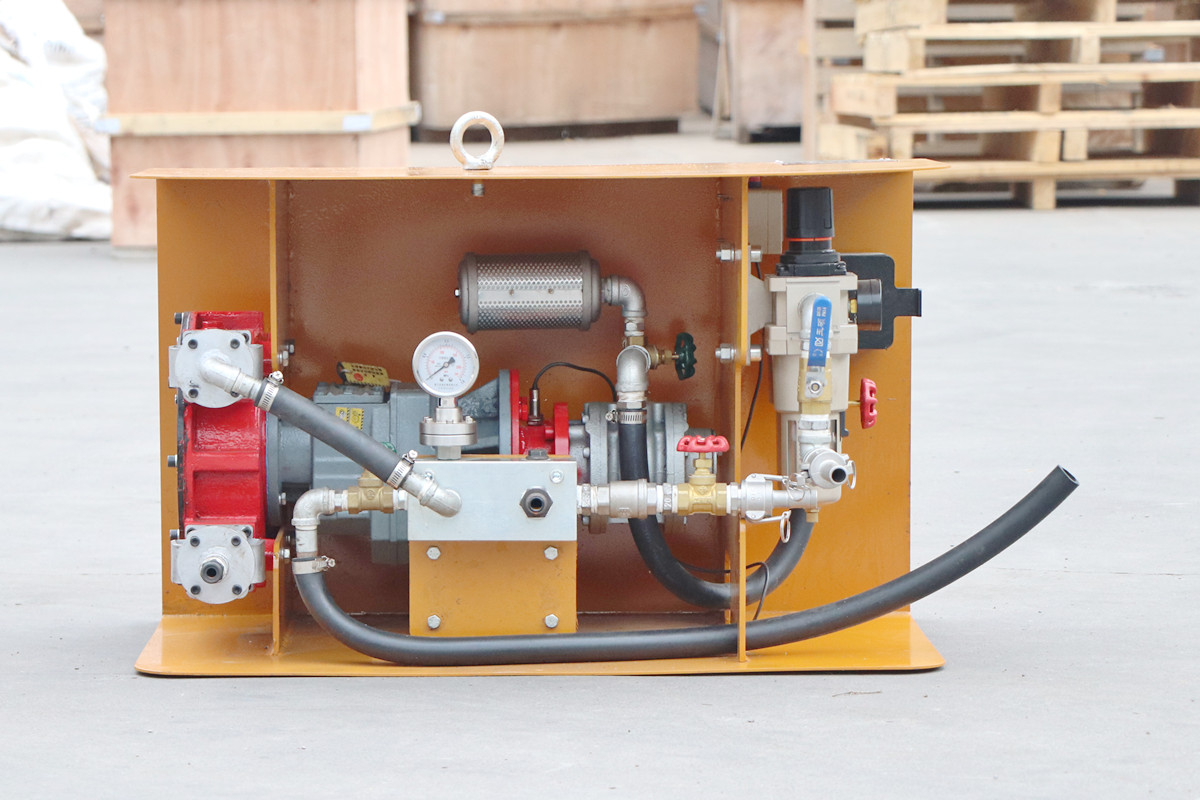

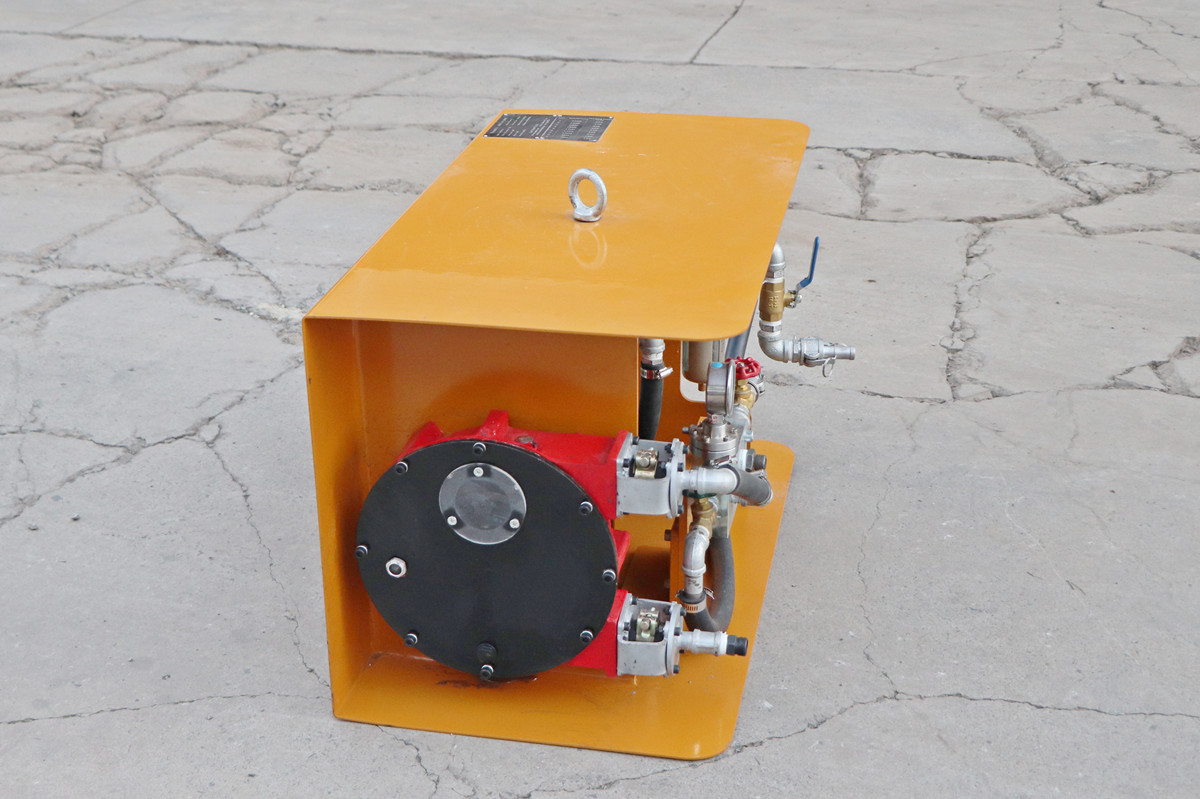

Pneumatic dry mix gunite machine

The pneumatic dry mix gunite machine is a specialized construction tool designed for applying gunite (dry-mix shotcrete) using compressed air. It’s ideal for spraying concrete, mortar, or refractory materials onto surfaces, making it popular in tunneling, slope stabilization, pool construction, and repair work.

Pneumatic dry mix gunite machine excels in projects requiring rapid, controlled application of gunite with minimal material waste. Its portability and efficiency make it a staple in underground construction, repair, and specialized concrete work.

Pneumatic dry mix gunite machine application:

Tunnel excavation: used for initial support and enhancing the stability of surrounding rock during tunnel excavation.

Underground structure: provides necessary structural support in the construction of underground spaces such as subway stations and basements.

Slope protection: reinforce mountain slopes to prevent geological disasters such as landslides.

Repair project: repair and reinforce old buildings or infrastructure.

How the pneumatic dry mix gunite machine works:

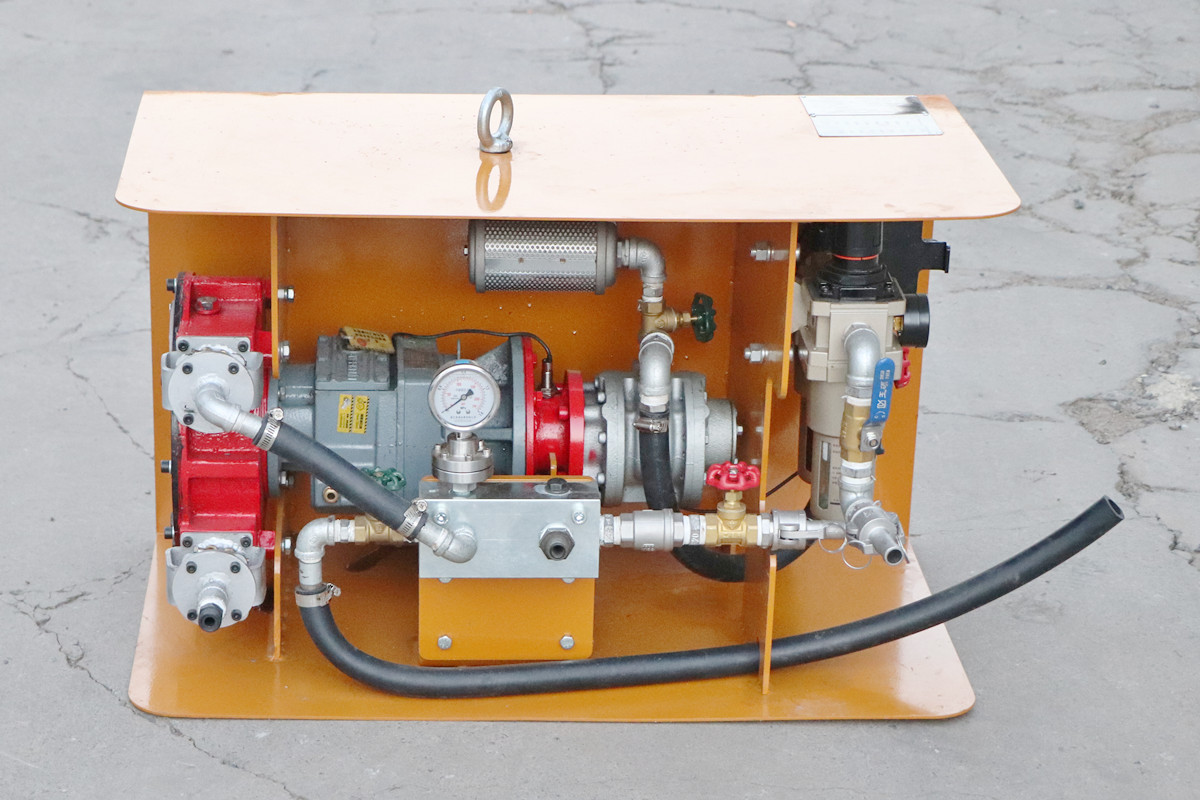

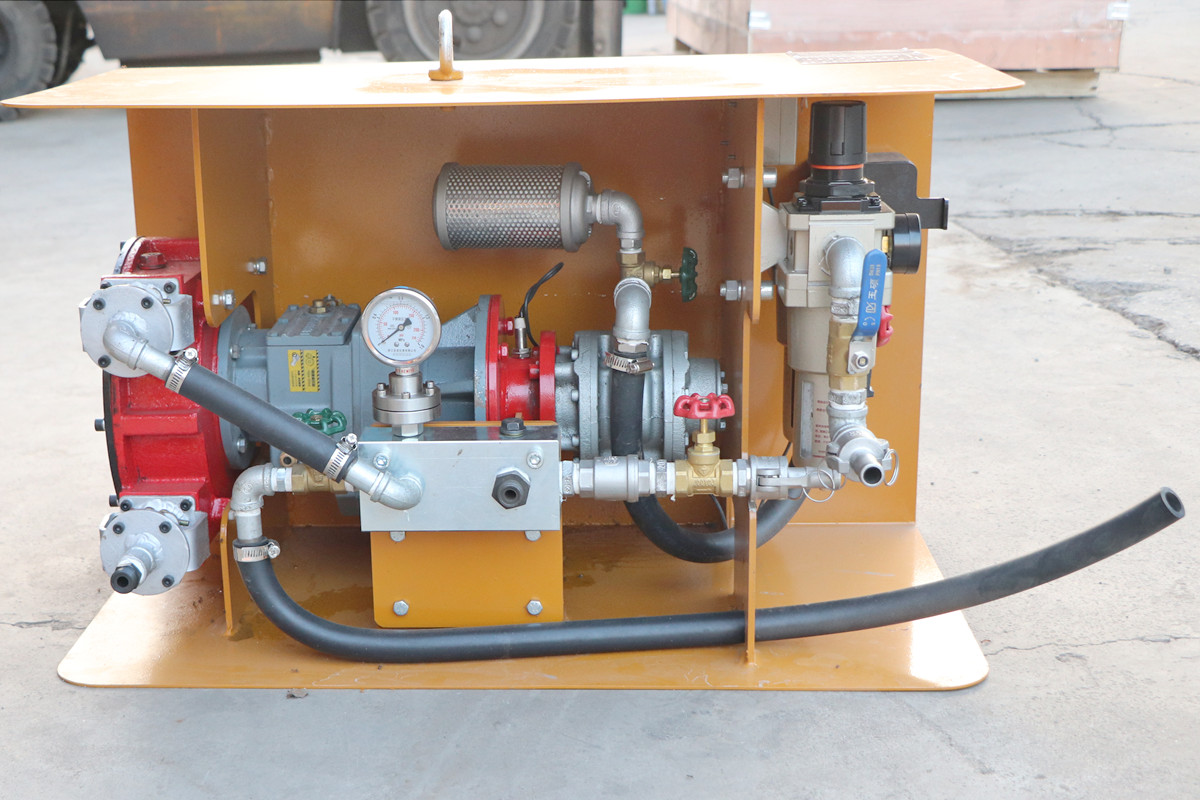

Dry Mix Preparation:

Pre-blended dry ingredients (cement, sand, aggregates, and additives) are loaded into the machine’s hopper.

No water is added at this stage, ensuring the mix remains dry and flowable.

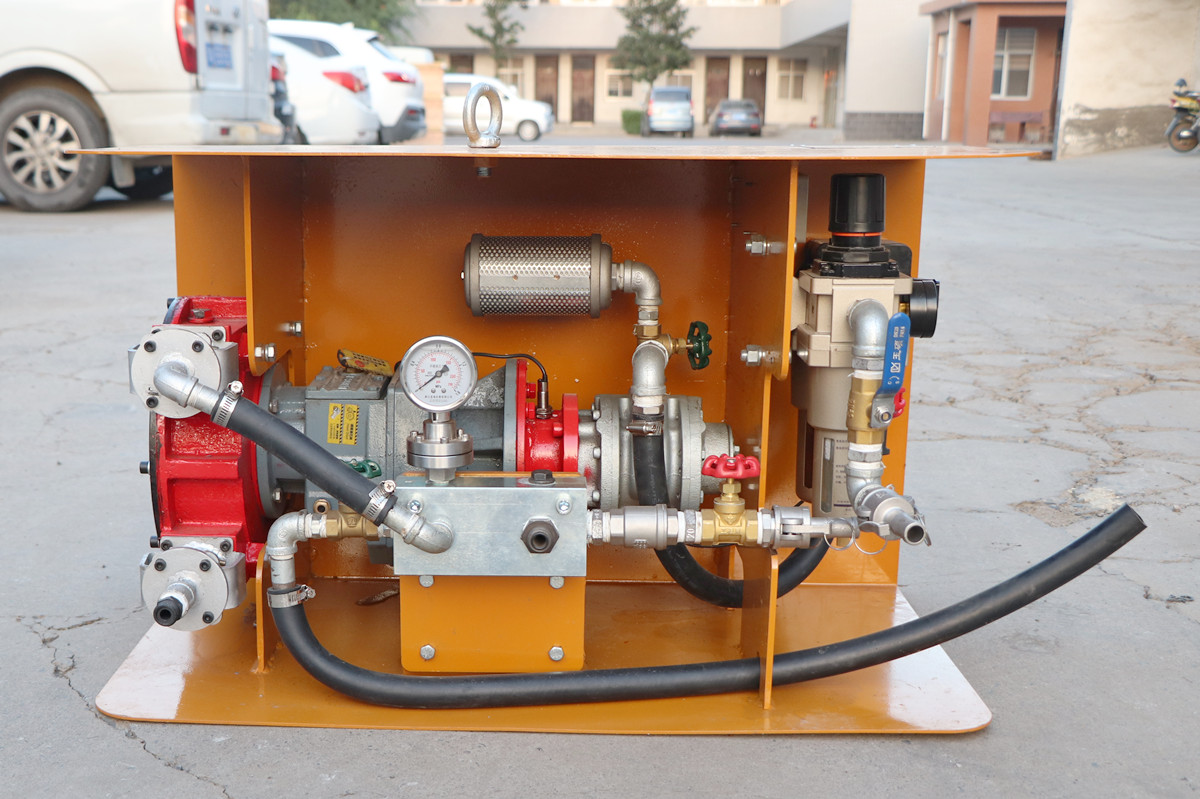

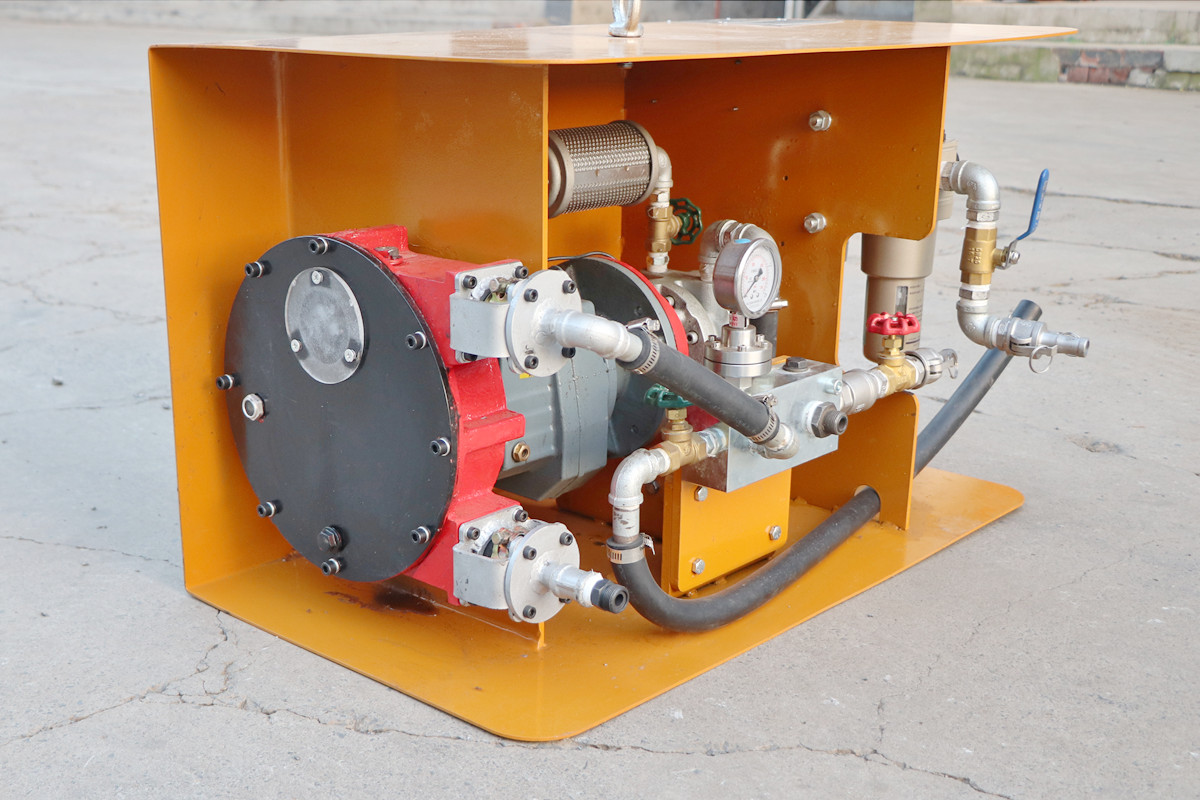

Pneumatic Conveyance:

A rotor or paddle mechanism feeds the dry mix into a high-velocity air stream generated by a compressor.

Compressed air (typically 60–100 psi) propels the mix through a delivery hose to the nozzle.

Nozzle Mixing:

At the nozzle, water is injected into the airstream via a water ring or injector.

The dry mix and water combine mid-air, creating a cohesive, sprayable slurry that bonds to the target surface.