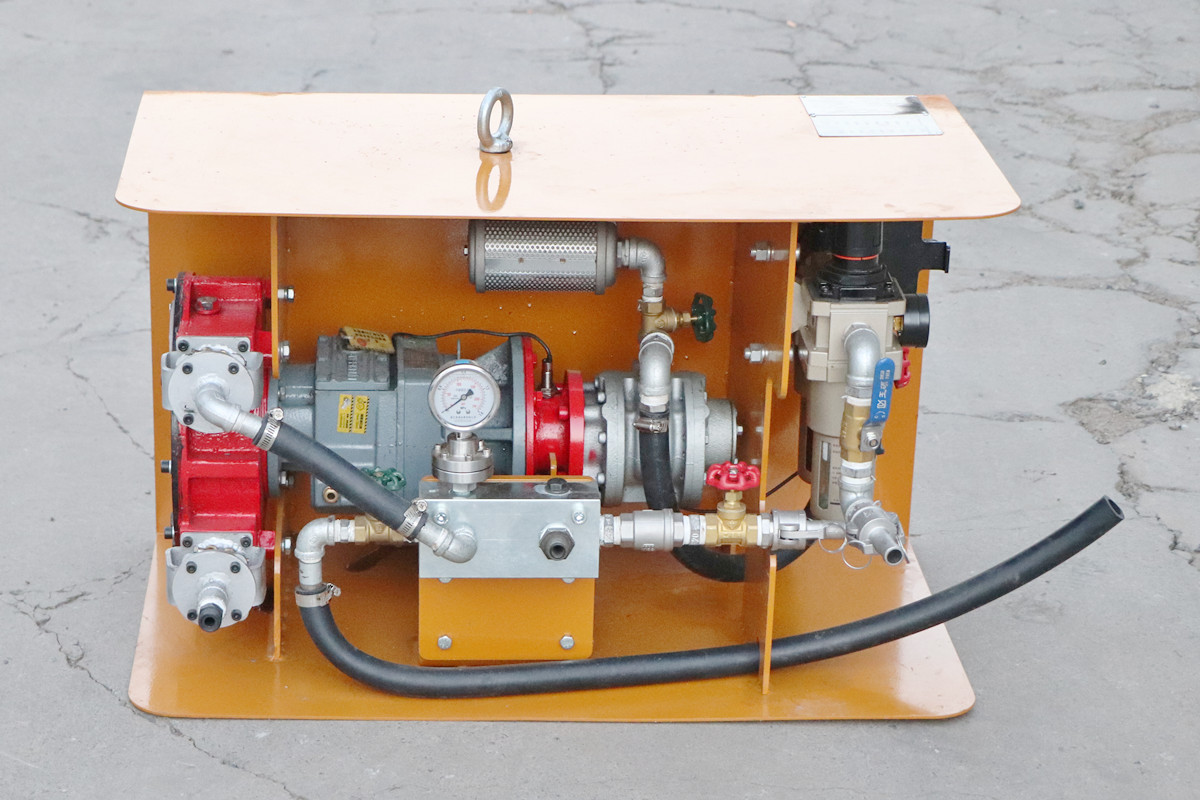

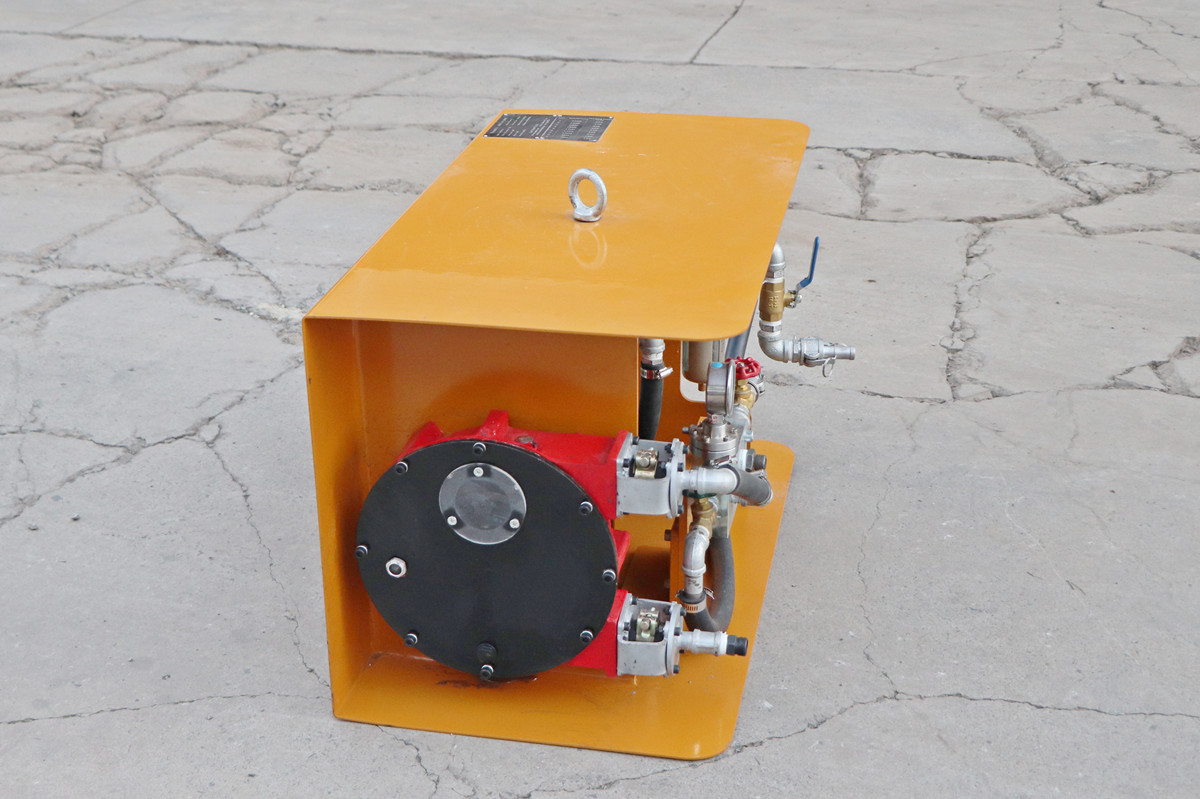

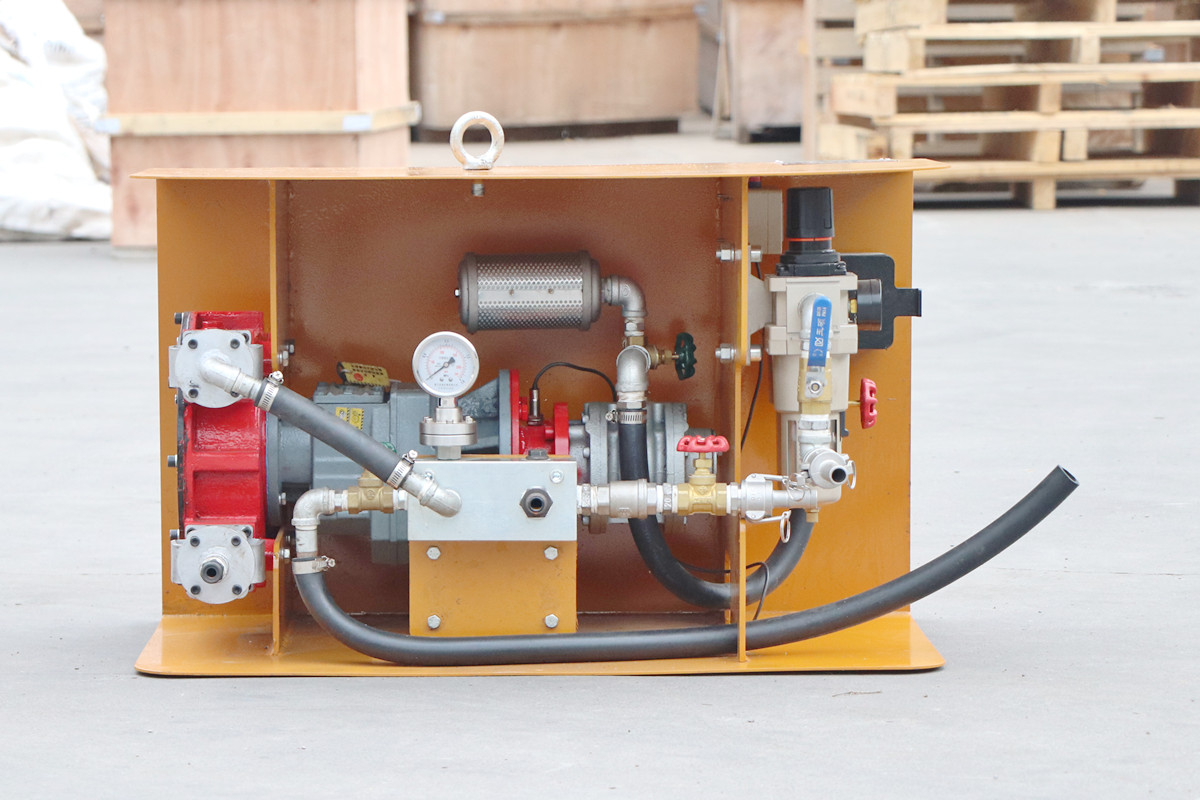

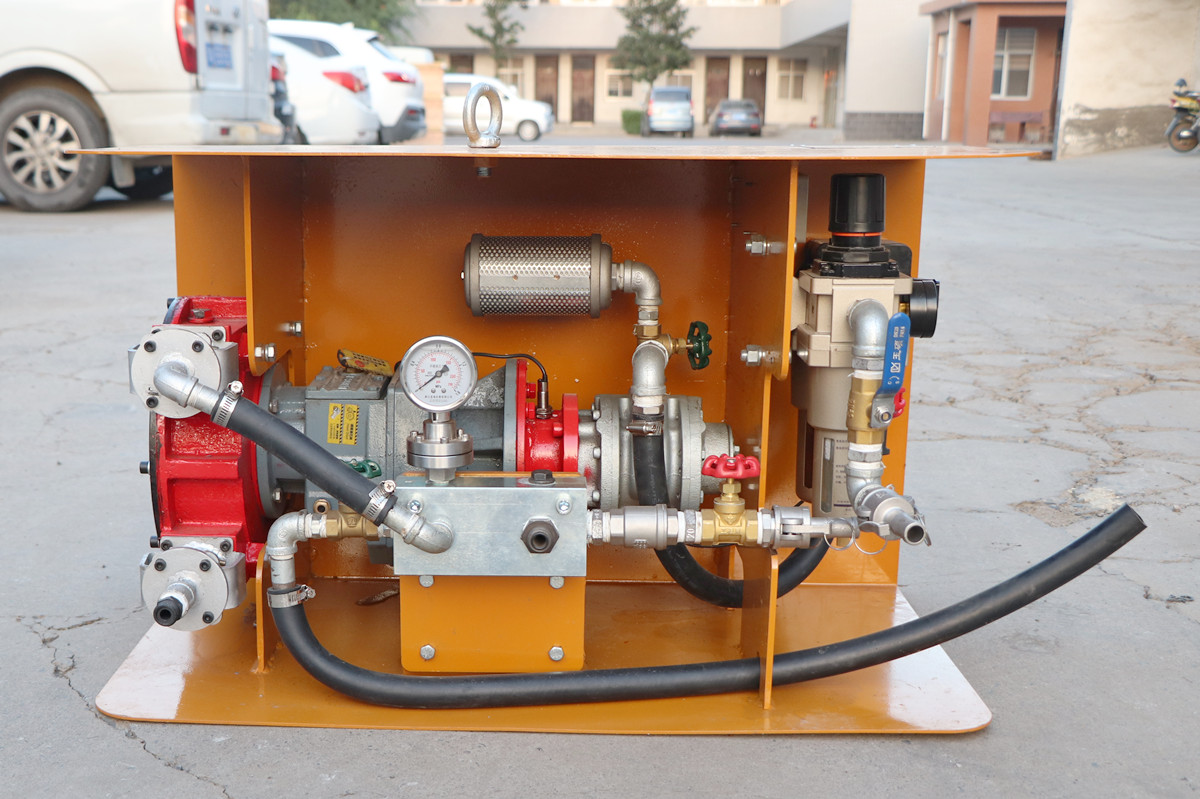

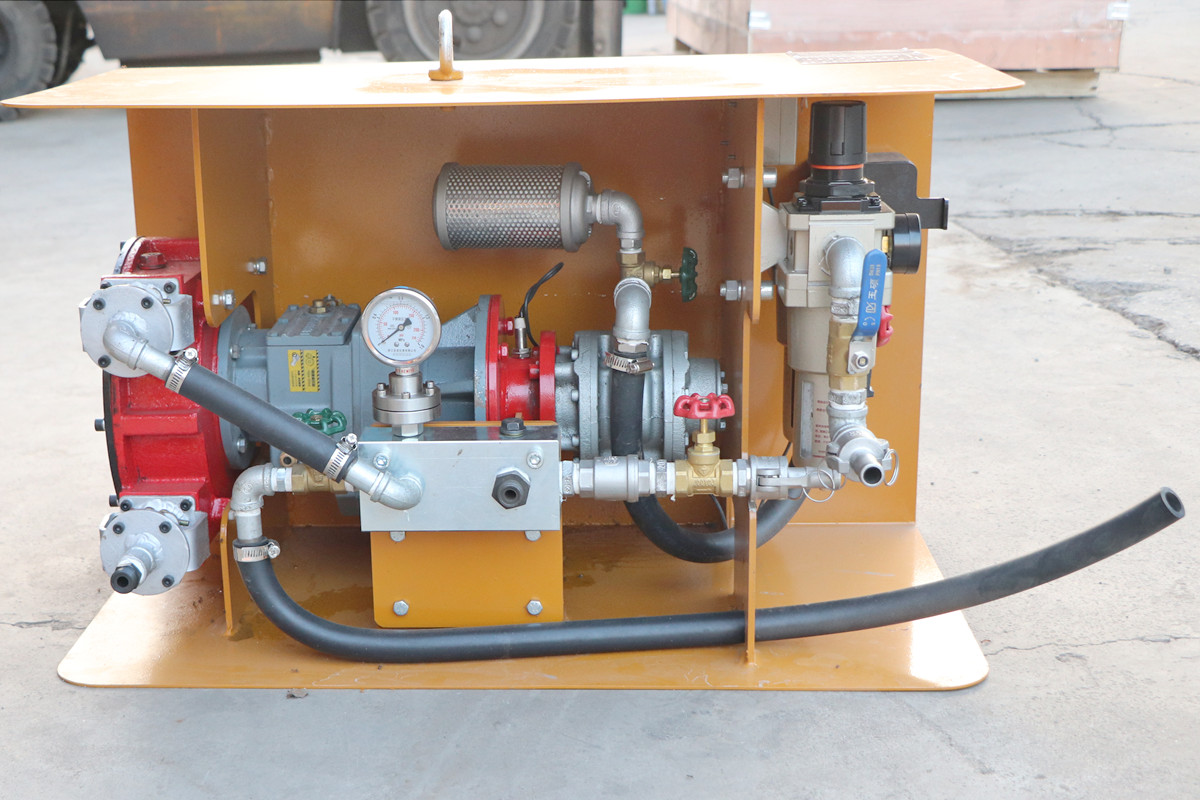

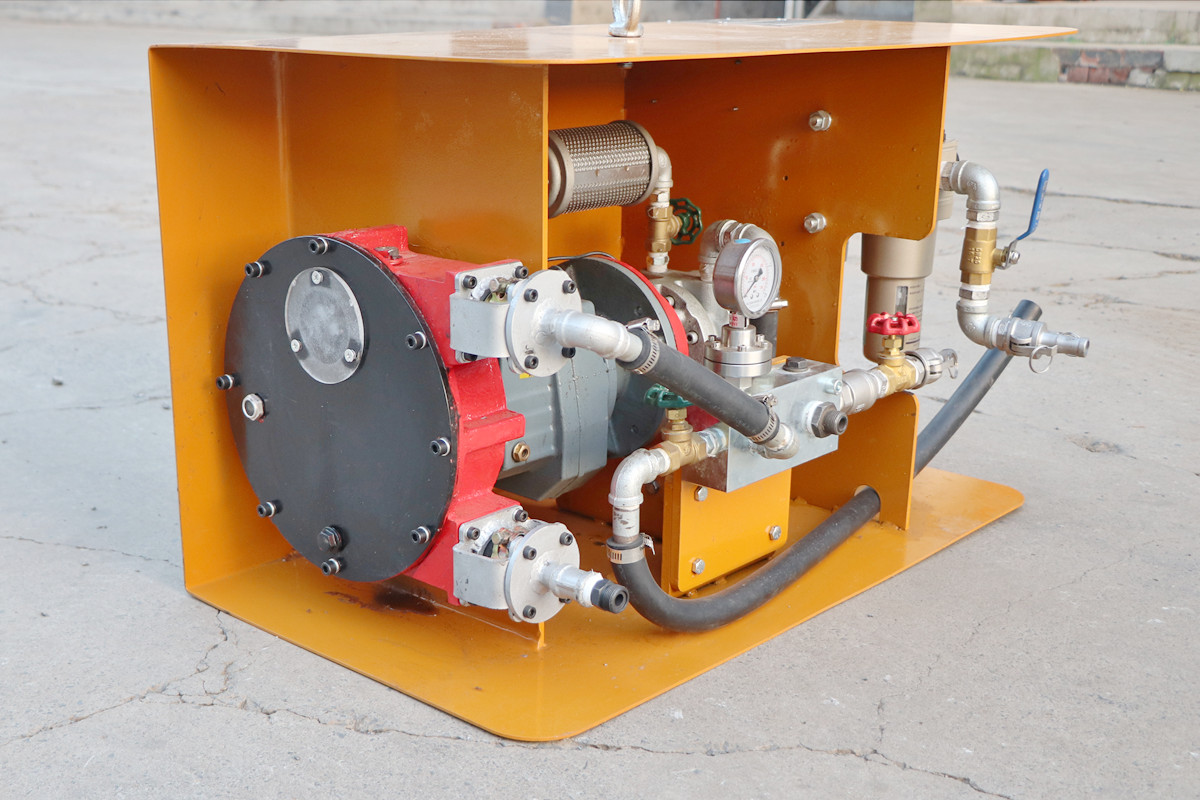

Pneumatic accelerator metering pump system

The pneumatic accelerated metering pump system usually consists of a pump body, a pneumatic servo device, a control system, etc. It uses compressed air as a power source and adjusts the stroke length (or flow rate) of the pump through a pneumatic servo device, thereby achieving accurate metering and accelerated delivery of liquids.

Working principle of pneumatic accelerator metering pump system:

Power source: The system uses compressed air as the power source, and converts the energy of the compressed air into mechanical energy through the pneumatic servo device to drive the pump body to work.

Stroke adjustment: The pneumatic servo device can adjust the stroke length of the pump according to the instructions of the control system, thereby changing the flow rate of the pump. This adjustment method has the characteristics of fast response speed and high adjustment accuracy.

Liquid acceleration: Inside the pump body, the liquid is accelerated and delivered to the target location. Since the pneumatic acceleration metering pump system adopts the pneumatic principle, it has high conveying efficiency and acceleration.

Pneumatic accelerator metering pump system characteristics:

High efficiency and energy saving: The pneumatic accelerator metering pump system uses compressed air as the power source. Compared with the traditional electric pump system, it has a higher energy efficiency ratio and can significantly reduce energy consumption.

Accurate metering: Through the precise adjustment of the pneumatic servo device, the system can achieve accurate metering of liquids to meet various process requirements.

Stable and reliable: The pneumatic accelerator metering pump system has a simple structure, stable operation, and high reliability and durability.

Easy to maintain: The system has relatively few components and is easy to maintain, reducing maintenance costs.

Application fields of pneumatic accelerator metering pump system:

Pneumatic accelerating metering pump systems are widely used in chemical, petroleum, pharmaceutical, food and other industries, especially in situations where accurate measurement and accelerated delivery of liquids are required, such as material proportioning in chemical reactions, liquid delivery in pharmaceutical production, etc.

Precautions of pneumatic accelerator metering pump system:

Compressed air quality: Ensure that the compressed air provided to the pneumatic accelerator metering pump system is clean and free of moisture and oil to avoid damage to the system.

Maintenance: Perform regular maintenance on the system, check the wear and tear of pneumatic servo devices, pump bodies and other components, and replace damaged components in a timely manner.

Safe operation: When operating the pneumatic accelerator metering pump system, relevant safety operating procedures should be followed to ensure the safety of personnel and equipment.

To sum up, the pneumatic accelerator metering pump system is an efficient, accurate and stable liquid delivery system with broad application prospects and development potential. During use, attention should be paid to issues such as compressed air quality, system maintenance and safe operation.