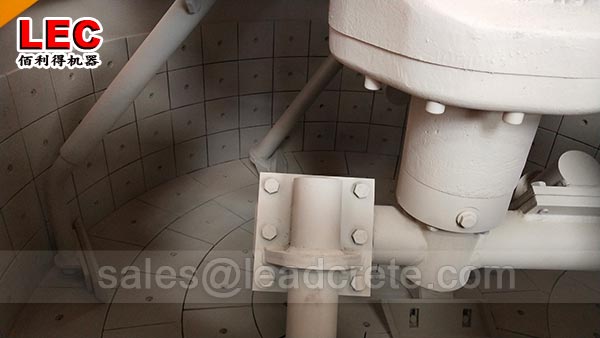

Planetary concrete mixer

The planetary concrete mixer can mix a variety of high-quality high-performance concrete, and can achieve homogeneous mixing in the shortest time.

The planetary concrete mixer with vertical shafts allow the rapid mixing of all types of quality concrete (dry, semi-dry and plastic). The great versatility of the mixer enables it to be used not only in the production of concrete, but also in the mixing of materials for the production of glass, ceramics, refractory materials, etc.

The planetary concrete mixer is equipped with a mechanical coupling and a hydraulic coupling (option), which can protect the transmission devices from overloads and impacts.

From optional model selection to customized mixers for special applications, we can also provide a full range of technical support and maintenance services.