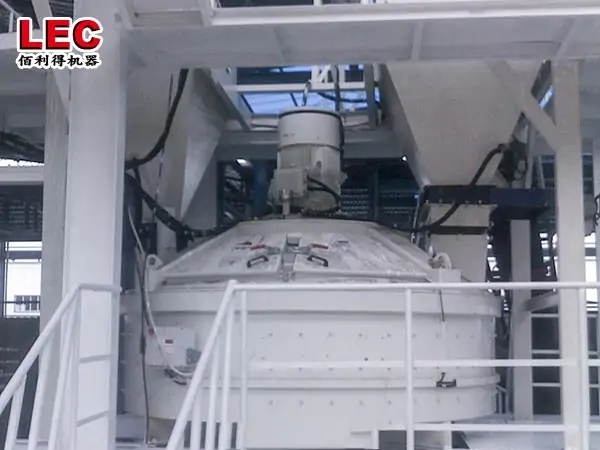

Planetary concrete mixer for construction

The planetary concrete mixer for construction is controlled by electrical equipment, easy to operate, and adopts a hydraulic discharge method. The discharge door is installed at the bottom of the equipment, which can reduce the labor intensity of the operator.

Planetary concrete mixer for construction is a kind of industry equipment with superior performance, compact structure, stable and reliable, and long service life, is affecting the development and development of the entire refractory industry. The planetary concrete mixer for construction is different from the traditional refractory mixer. It adopts the planetary mixing mode and drives the rotating body to run through the planetary reducer.

The mixing arm does both rotation and revolution movement. The mixing movement track is complex and the mixing movement is strong. The mixing effect of the planetary concrete mixer for construction is amazing and the mixing material is compared with the same material ratio and the same feeding sequence.

Uniform and high quality. In order to pursue a more adequate and uniform mixing effect, and solve a large number of fine and high-homogenous mixing process problems in many industries such as building materials, refractories, casting, and chemical industries, we provides a vertical shaft type planetary mixing machine .