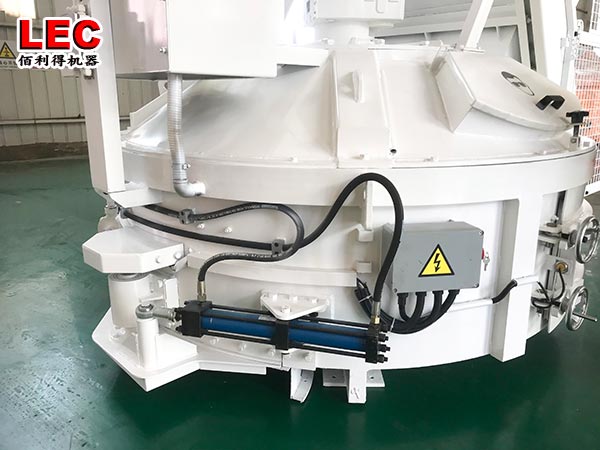

Planetary type concrete mixer for ceramic

The planetary type concrete mixer for ceramic is more suitable for the automatic refractory production line. The vertical shaft concrete mixer is set to automatically feed, stir, discharge, and then continue the next process through the conveying device.

The emergence of the planetary type concrete mixer for ceramic has provided production assistance for industries such as concrete, and it is a very important mixing and mixing machine for many industry users. The planetary type concrete mixer for ceramic is now replacing the general mixer and has shown irreplaceable advantages in many industries such as PC and high-performance concrete. The main reason is because of the advantages of use performance.

There are various stirring forms in the stirring process of the planetary type concrete mixer for ceramic, which can effectively knead, disperse, shear, and stir the stirring material quickly, and also prevent the material from settling, so the stirring material has no agglomeration phenomenon, and the new stirring material is stable. High workability and short mixing time.