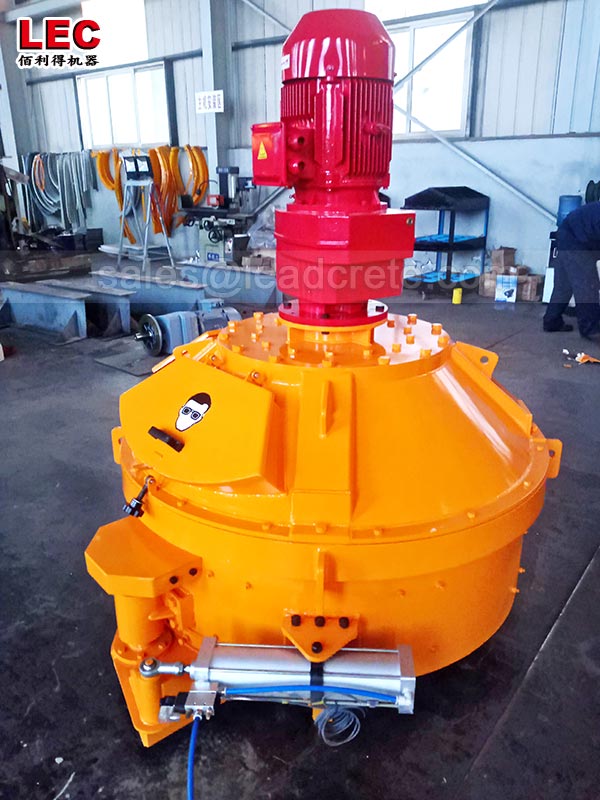

Planetary mixing machine

Planetary mixing machine covers an area of small, refractory castable can be used for internal processing space, volume ratio is good, planetary mixing machine automation level is high, automatic cleaning, easy maintenance, dust and leakage prevention, simple to use. The components of the planetary mixing machine are reliable, and the wearing parts are provided by us for a long time and are easy to replace.

The planetary mixing machine is a kind of mixing and granulation equipment extended from the powerful mixer. Users who choose granulation equipment are more inclined to mixed granulation equipment with advanced technology, reliable operation and high processing and adaptability. The planetary mixing machine meets the standards of industry users and can meet customer production requirements. In terms of production efficiency, planetary mixing machinecontinuously increases scientific research investment, continuously improves production efficiency, and improves energy utilization under the premise of effective production energy consumption. This not only guarantees production quality, but also highlights the advantages of Leadcrete machinery and equipment.