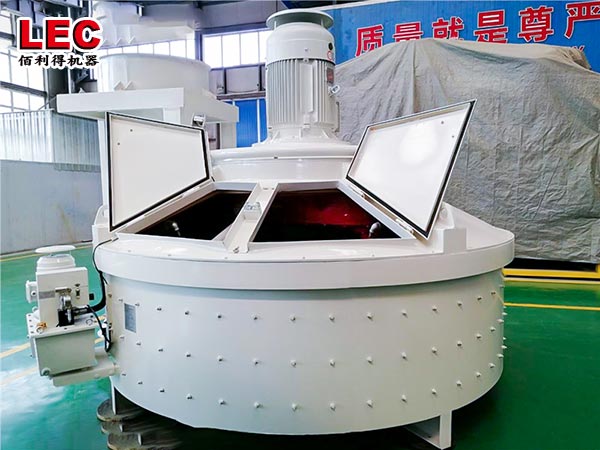

Planetary Mixer Equipment

Planetary Mixer Equipment can be used to mix all types of high-quality concrete (dry, rigid, semi-rigid, and plastic concrete) and achieve high homogeneity in the quickest time possible. It can also be used in glass, ceramics, refractories, and other industries.

Planetary mixers provide for quick mixing of all sorts of high-quality concrete (dry, semi-dry and plastic). The Planetary Mixer Equipment’s versatility allows it to be utilized not only in the manufacturing of concrete, but also in the production of glass, ceramics, refractory materials, and other materials.

Planetary Mixer Equipment’s gearbox unit (patent technology) is uniquely built for a balanced transfer of power to the various mixing devices, ensuring low-noise spinning without backlash even under extreme working conditions.

This unit takes up less space than a standard gearbox, and the mixer’s maintenance area can be increased by 30%.