Planetary concrete for sale India

Leadcrete Equipment also has its own technical team and with research and development ability, please send the application of the planetary concrete for sale India or the parameter information you need to our email ID sales@leadcrete.com, we will offer solution according to your demands to you.

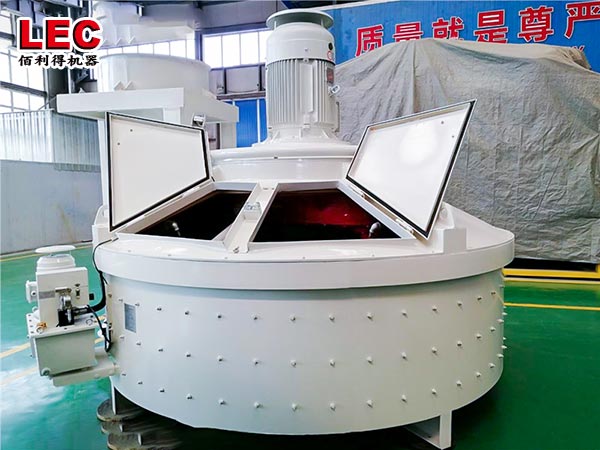

Planetary concrete for sale India utilize a new design type and processing technology for intense mixing of materials that promotes rapid transitions in mixing during mixing. UHPC planetary mixer consists of vertical circular tube, rack, planetary mixing plate, motor and reduction box.

The mixing device of the Planetary concrete for sale India has a comprehensive and fast running trajectory, and the mixing process has strength and toughness. The mixing operation of the UHPC planetary mixer can shear the sintered material without destroying the inherent shape of the raw material, and the equipment has no dead spots when mixing.