Home » Planetary concrete mixer » Mixer for refractory castable

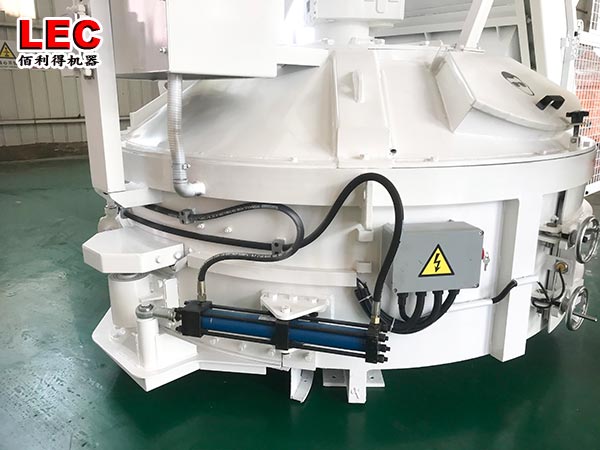

Mixer for refractory castable

We also have the mixer for refractory castable has the mixing capacity of 100KG, 250KG, 500KG, 1000KG, 1250KG or other. If you are interested in the mixer for refractory castable, please leave your contact information, we can send the mixer for refractory castable price for you!

Contact Us

Get Price

Share:

Next:

Big concrete mixer

Content 2021-11-24

The mixer for refractory castable is made of high wear resistance and has good wear resistance. The uniquely designed blades can achieve high-speed and uniform mixing. The mixer for refractory castable is equipped with a soft protection device motor, which can effectively buffer the damage to the machine starting.

The mixer for refractory castable also provides an intermittent and continuous mixing tank, and the materials transported therein are processed with the most advanced technology. The new material wall bottom in the mixing box can effectively prevent accumulation on the wall and bottom of the mixing box.

In the use of mixer for refractory castable, it is more important to note that operators must undergo pre-job training and master certain operating techniques, so that the best performance of the mixer can be exerted on the premise of ensuring personnel safety.

Inquiry

More Planetary concrete mixer