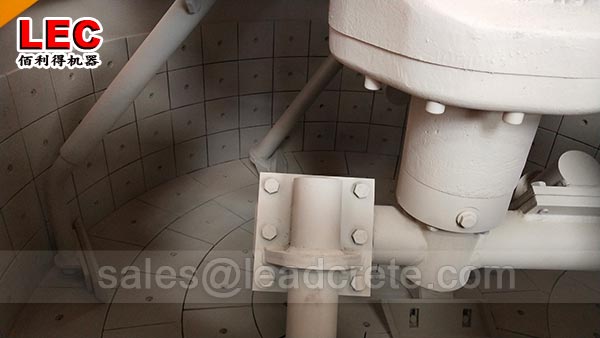

Industrial Planetary Mixer For Construction

Construction machinery. Plastic concrete and low flow concrete can both be mixed in a planetary mixer. It is commonly utilized in common building sites, including as road and bridge construction, as well as small and medium-sized concrete component factories.

Our company’s construction equipment planetary mixers have all received ISO9001 quality assurance and SASO certification. Some overseas companies have long-term and robust business relationships with our company.

Construction equipment and technology services are our key exports. We are actively expanding our foreign operations, which span a wide range of countries and regions.

Construction machinery.The planetary mixer may be used to mix all types of high-quality concrete (dry, rigid, semi-rigid, and plastic concrete) and achieve excellent homogeneity in the quickest period possible. It can also be used in glass, ceramics, refractories, and other sectors.