Home » Planetary concrete mixer » industrial planetary concrete mixer

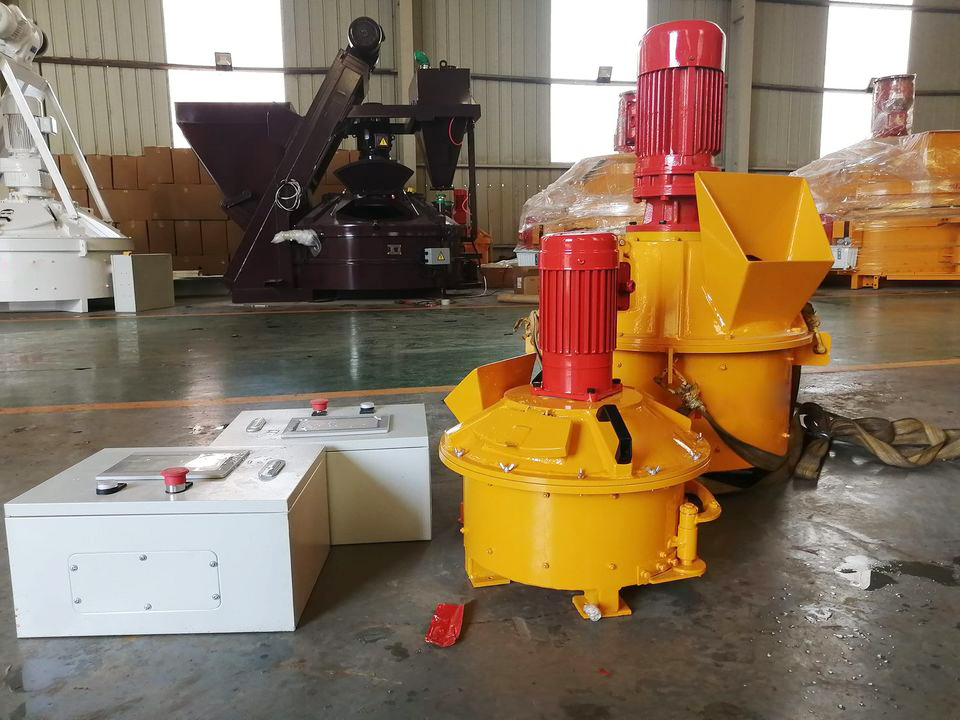

industrial planetary concrete mixer

industrial planetary concrete mixer can be applied to mix glass, ceramics, refractories and other industries.

Contact Us

Get Price

Share:

Previous:

Hottest concrete mixer products

Content 2022-02-22

The specially developed gear box (patented technology) of our industrial planetary concrete mixer can evenly and effectively distribute power to each stirring device. Even under harsh production conditions, the mixer can ensure high-efficiency and low-noise operation. While saving space, the mixer maintenance space is increased by 30% compared to conventional gearboxes.

Industrial planetary concrete mixer is designed according to Europe CE Standard. It improves the mixing efficiency compared with traditional type.

Inquiry

More Planetary concrete mixer