Home » Planetary concrete mixer » high speed planetary concrete mixer

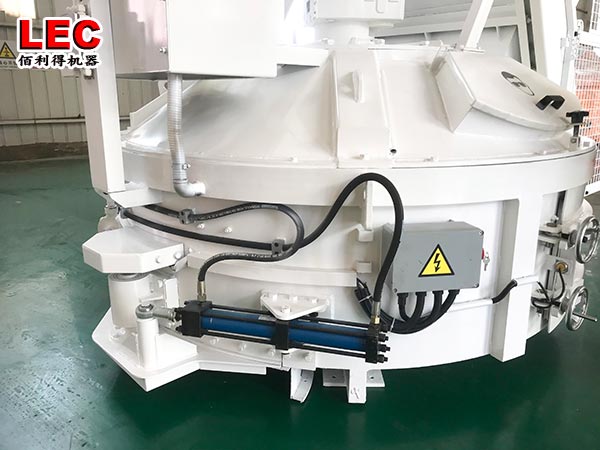

high speed planetary concrete mixer

The high speed planetary concrete mixer has a good mixing effect, high uniformity, high production efficiency, and fast mixing speed.

Contact Us

Get Price

Share:

Content 2022-04-11

The high speed planetary concrete mixer has good sealing performance and will not cause environmental pollution. The scientific structure design enables the mixer to be used in various production line layouts.

The high speed planetary concrete mixer can design the mixing speed according to the different formulations of the product. The wear-resistant alloy casting has a high-speed flying knife, which has extremely high wear resistance and high mixing strength.

Inquiry

More Planetary concrete mixer