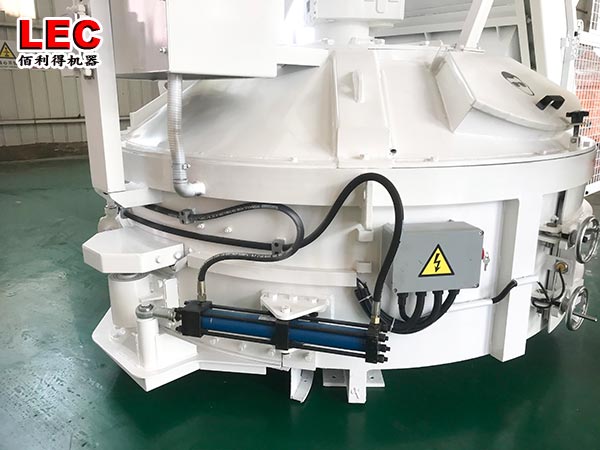

Heavy duty concrete mixer

All packing prepares Heavy duty concrete mixer for shipment in a manner deemed to be safe, preventing damage or corrosion to product, and satisfying customer requirements.

Our requirements of heavy duty concrete mixer:

1. Unpainted surface are to be coated or packaged to prevent corrosion or damage.

2. At a minimum, Heavy duty concrete mixer will be skidded, blocked, and banded down or constrained in a manner to prevent shifting and undesirable movement in transit.

3. When blocking product Heavy duty concrete mixer is required that all blocks/ supports be placed under stationary features and will not shift during transit. Straps/Chains from the truck should then be placed over those supports when applicable.

4. Gearbox representative must verify that the load, chains/straps and tarp are assembled in such a way to avoid damage to the product during transit.