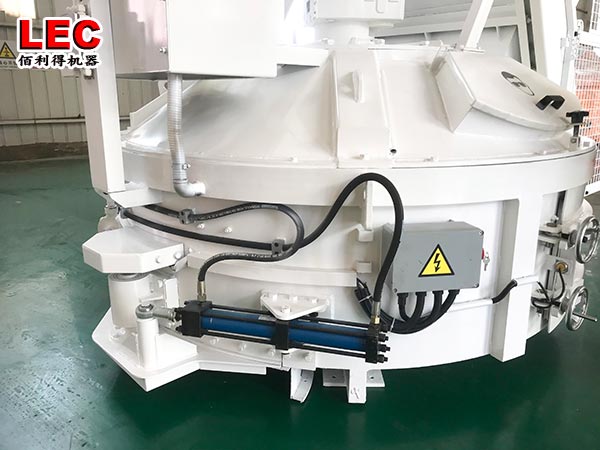

Electric planetary concrete mixer

For electric planetary concrete mixers, many readers will also seek to introduce them. Is there a mixer with good quality and appropriate price? Today we will unveil an electric planetary concrete mixer.

In recent years, the industry of electric planetary concrete mixers has been very popular. Due to the rapid development and application of building materials and concrete, more and more investors are coming.

Advantages of Electric planetary concrete mixer:

(1) The electric planetary concrete mixer has no poor batch processing, and high precision, is very suitable for laboratory use, and the accuracy of data is guaranteed;

(2) The electric planetary concrete mixer has small space, fast speed, good dynamic response, and no noise;

(3) The electric planetary concrete mixer has a compact structure, high rigidity, and large bearing capacity.