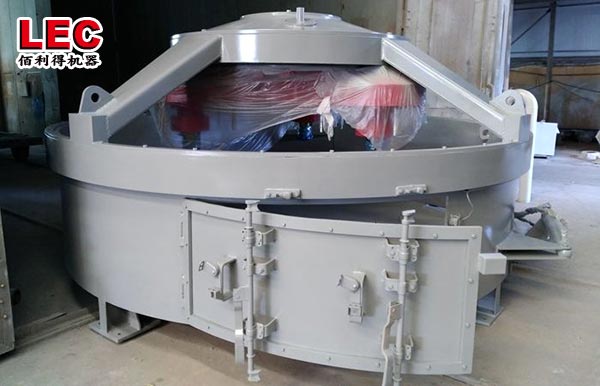

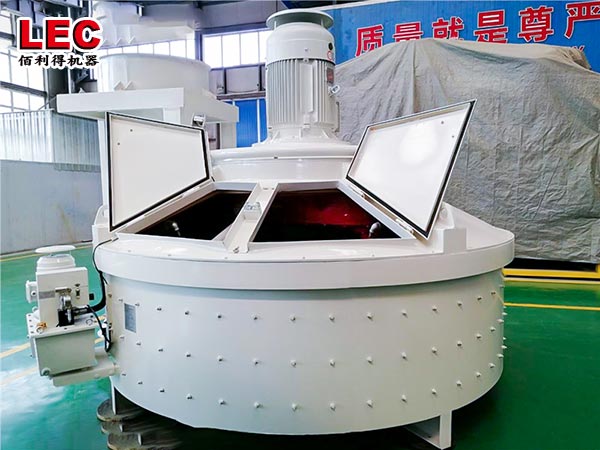

Electric engine concrete pan mixer manufacturers

We are electric engine concrete pan mixer manufacturers and supplier from China, any interest our electric engine concrete pan mixer, you can tell me freely.

Electric engine concrete pan mixer is driven by a specially designed hard tooth surface reducer, which makes the stirring motion not only rotate but also rotate, high efficiency and even quality. The agitator blade is designed as a diamond structure and can be worn according to actual use Rotate 180 ° for use again.

Electric engine concrete pan mixer compared with double shaft mixer’s advantage is its stirring arm trajectory more complex and more dense,almost no stir dead Angle, for material mixing more fully, and does not exist the problem of shaft end seal is suitable for mixing high performance and dry hard materials.