Dry and Wet Shotcrete Machine for Dam Construction

Case analysis of dry and wet shotcrete machine for dam construction:

Dry and wet shotcrete machines have been widely used in many dam construction projects. For example, in the construction of a large hydropower station dam, a wet shotcrete machine was used for concrete spraying. By precisely controlling the spraying pressure and spraying angle, the flatness of the dam surface and the density of the concrete are ensured. At the same time, the efficient working performance of the wet shotcrete machine also greatly improves the construction efficiency and shortens the construction period.

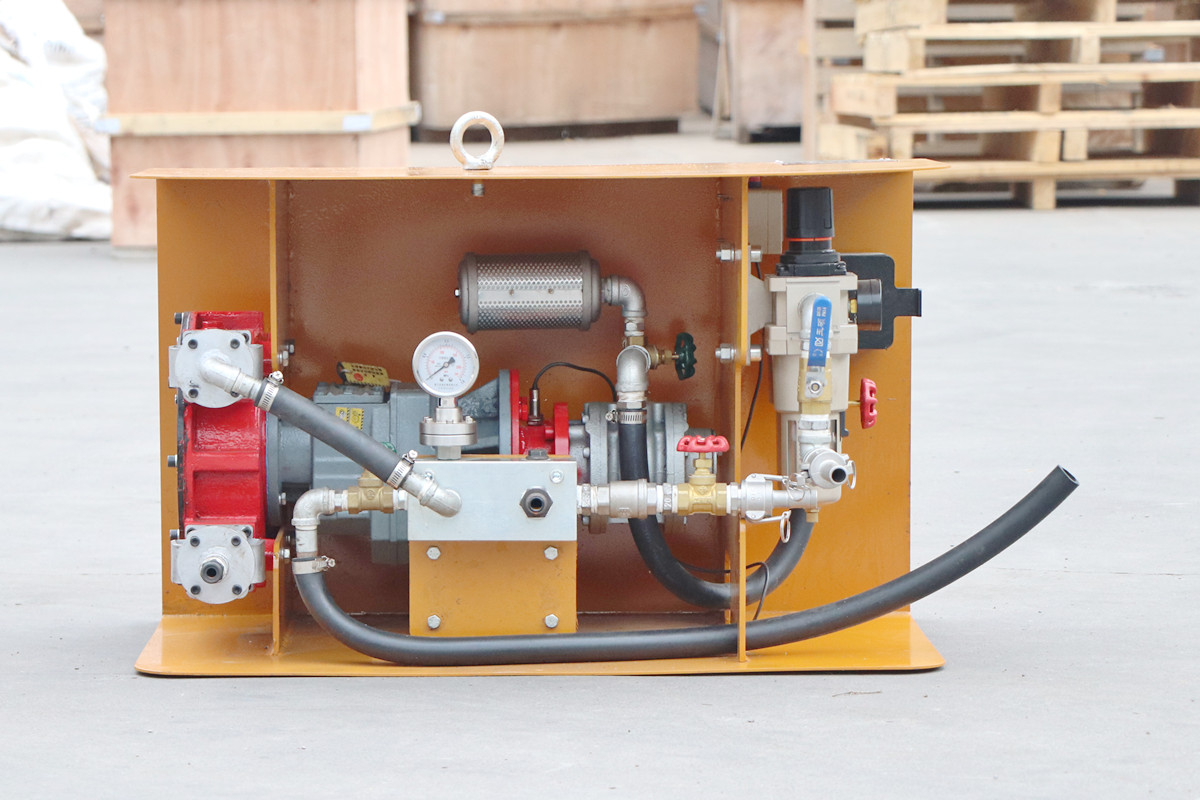

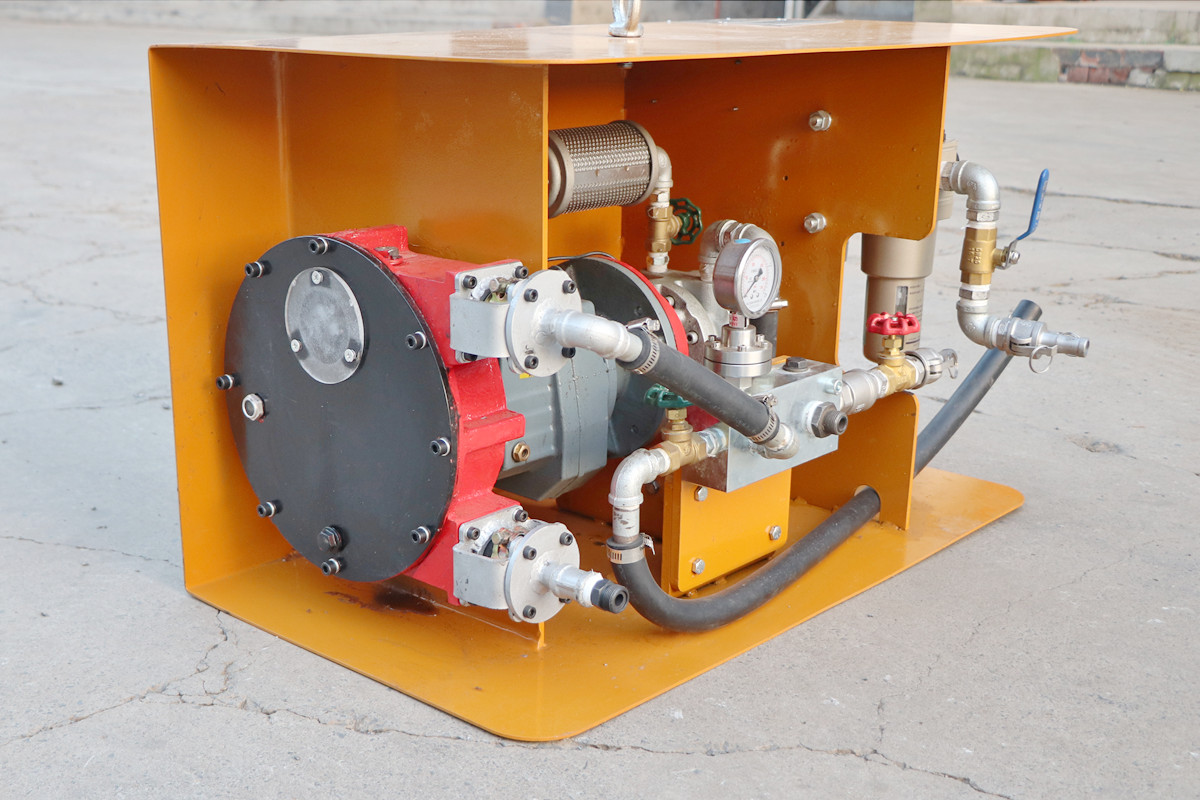

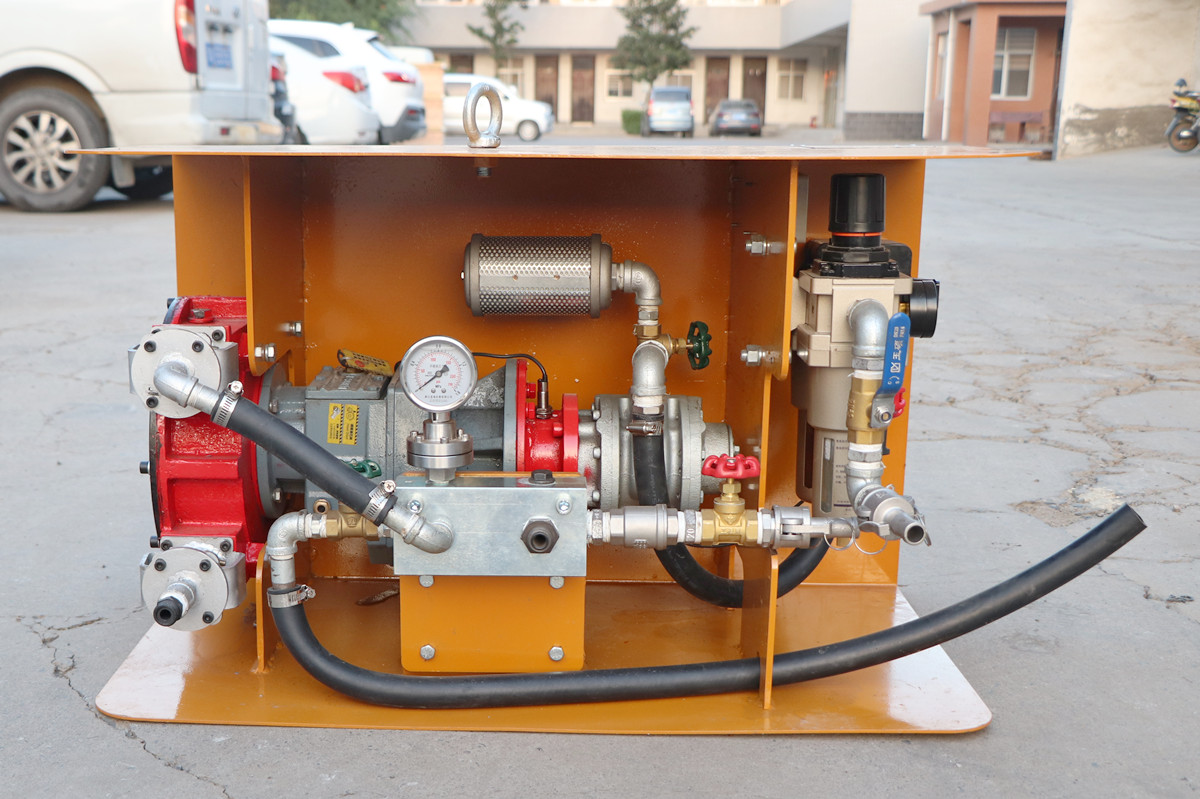

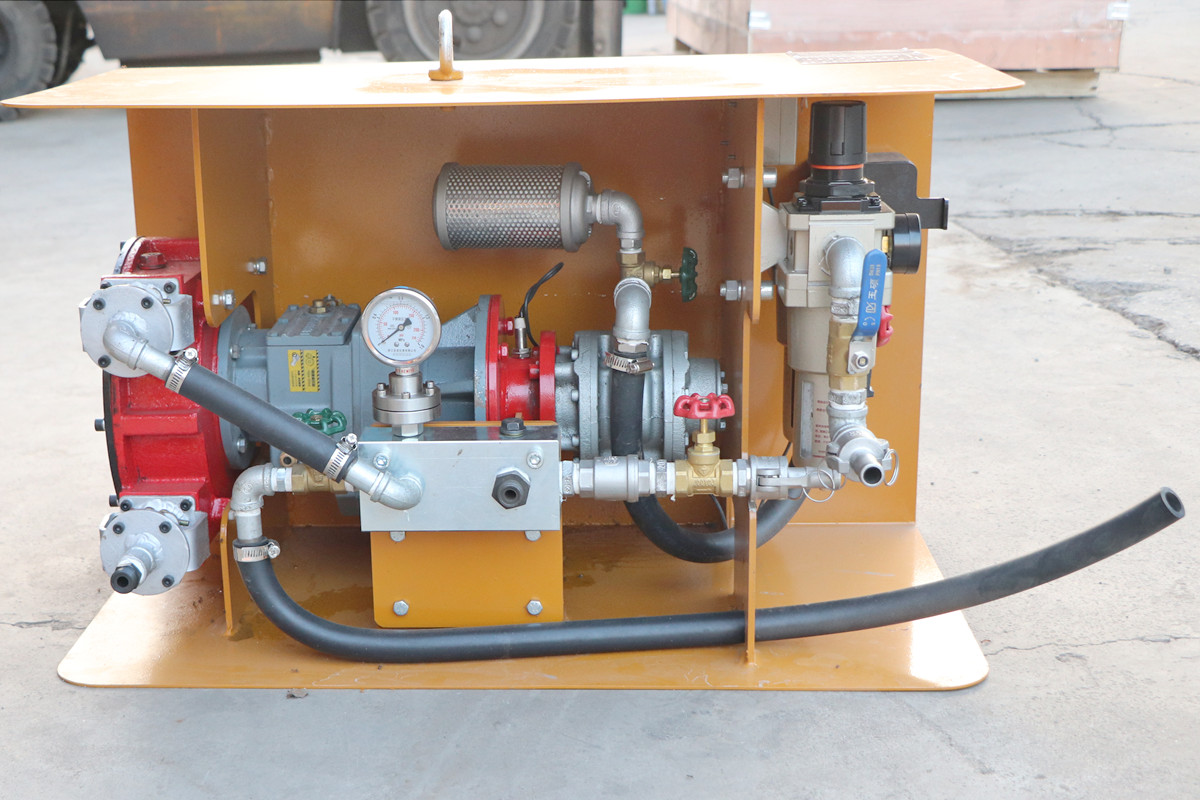

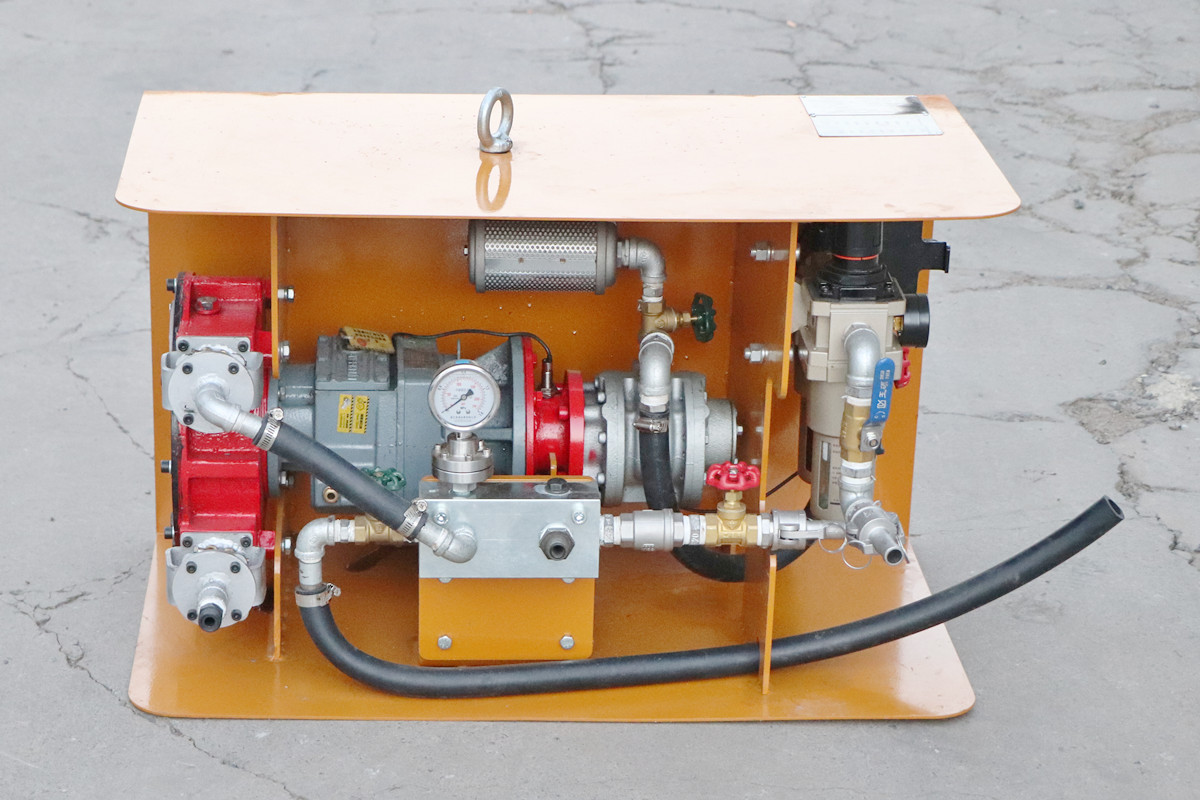

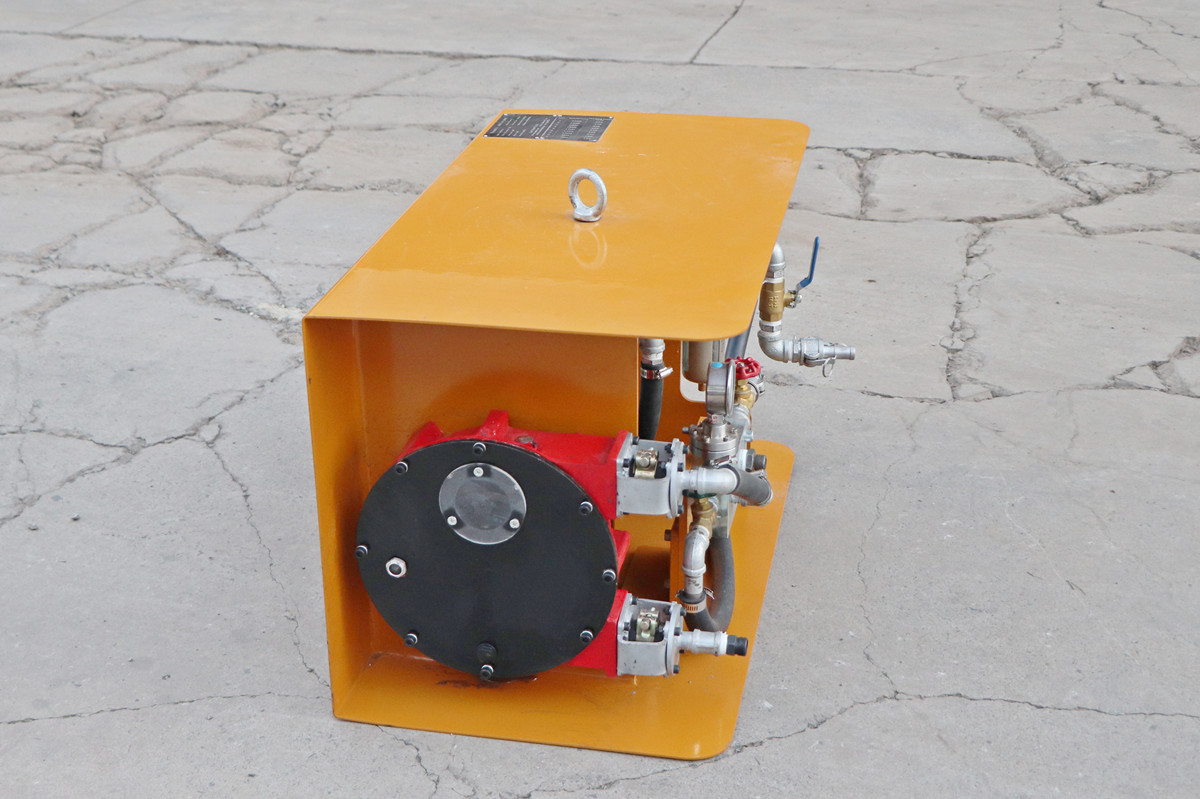

Dry and wet shotcrete machines are a type of mechanical equipment specially used for spraying concrete. According to the state of the concrete mixture, they can be divided into two types: dry shotcrete and wet shotcrete. The concrete mixture used by the dry shotcrete machine is dry, and it is sprayed out after mixing with water through the spraying device inside the machine; while the wet shotcrete machine directly uses pre-mixed wet concrete for spraying.

Dry and wet shotcrete machines types and features:

Dry shotcrete machine:

Features: Dry shotcrete machines usually have the characteristics of compact structure, easy operation, and flexible movement.

Application: Suitable for occasions where the requirements for concrete strength are not particularly high and fast spraying is required.

Wet shotcrete machine:

Features: Wet shotcrete machines can ensure the uniformity and density of concrete, and the spraying effect is better. At the same time, wet shotcrete machines also have the advantages of high work efficiency and less concrete waste.

Application: Suitable for occasions with high requirements for concrete quality in dam construction, such as the main structure of the dam, waterproof layer, etc.

Dry and wet shotcrete machines application in dam construction:

Concrete spraying:

Dry and wet spraying concrete machines can spray concrete evenly onto the surface of the dam to ensure the integrity and stability of the dam.

By adjusting the spraying pressure and spraying angle, accurate spraying of different parts of the dam can be achieved.

Concrete density control:

Dry and wet spraying concrete machines can ensure that the density of concrete meets the design requirements, thereby improving the impermeability and durability of the dam.

By adjusting the concrete ratio and spraying process parameters, effective control of concrete density can be achieved.

Improved construction efficiency:

Dry and wet spraying concrete machines have efficient working performance and can greatly improve the efficiency of dam construction.

At the same time, the ease of operation of the machine also reduces the labor intensity of construction personnel and improves the safety of construction.

Shotcrete machine selection and maintenance:

Machine selection:

When selecting a dry and wet spraying concrete machine, factors such as the specific requirements of dam construction, the ratio of concrete, spraying distance and spraying angle need to be considered.

At the same time, factors such as the machine’s performance parameters, brand reputation and after-sales service also need to be considered.

Machine maintenance:

Dry and wet shotcrete machines need to be regularly maintained and serviced during use to ensure their normal working performance and extend their service life.

Maintenance includes cleaning concrete residues inside and outside the machine, checking the wear of the machine and replacing wear parts in time.

In summary, dry and wet shotcrete machines have broad application prospects and important value in dam construction. By reasonably selecting and using such machines, the quality and efficiency of dam construction can be ensured, providing strong guarantees for water conservancy project construction.