Home » Planetary concrete mixer » Counter current planetary mixer for glass

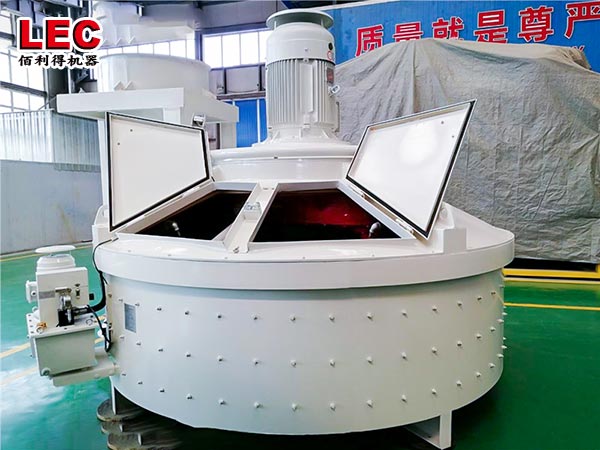

Counter current planetary mixer for glass

The counter current planetary mixer for glass has many models, rich equipment functions, adjustable speed, and the planetary mixing track brings more advantages to the mixing uniformity, and also solves the needs of users who pursue high homogeneity mixing, so this model is currently very popular with Uhpc A favorite of ultra-high performance concrete producers.

Contact Us

Get Price

Share:

Content 2022-05-13

The motor and deceleration device of the counter current planetary mixer for glass has the high bearing quality and strong load capacity. The motor, deceleration device and transmission system constitute a good dynamic motion system, which provides a basic guarantee for efficient uhpc mixing.

Inquiry

More Planetary concrete mixer