Home » Planetary concrete mixer » Construction machine concrete planetary mixer

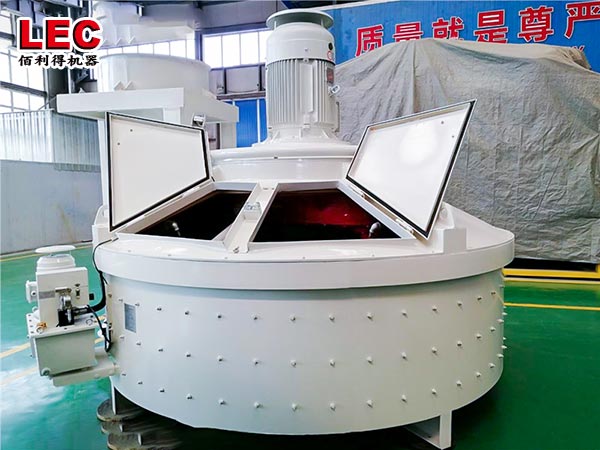

Construction machine concrete planetary mixer

Our business involved in sales and after sale service, designing and installation of construction machine concrete planetary mixer, entire concrete production control system improvement, entire concrete mixing plant.

Contact Us

Get Price

Share:

Content 2021-11-08

We have advanced equipments for R&D and production. There are 15 professionals working in designing, manufacturer, and researching of concrete equipments and production line for more than 20 years, so that we own the powerful ability in the construction machine concrete planetary mixer fields and the entire concrete production line.

Advanced planetary motor and gearbox of construction machine concrete planetary mixer is adopted to make the whole machine run stably, durably, in low noise and with large output torque.

Inquiry

More Planetary concrete mixer