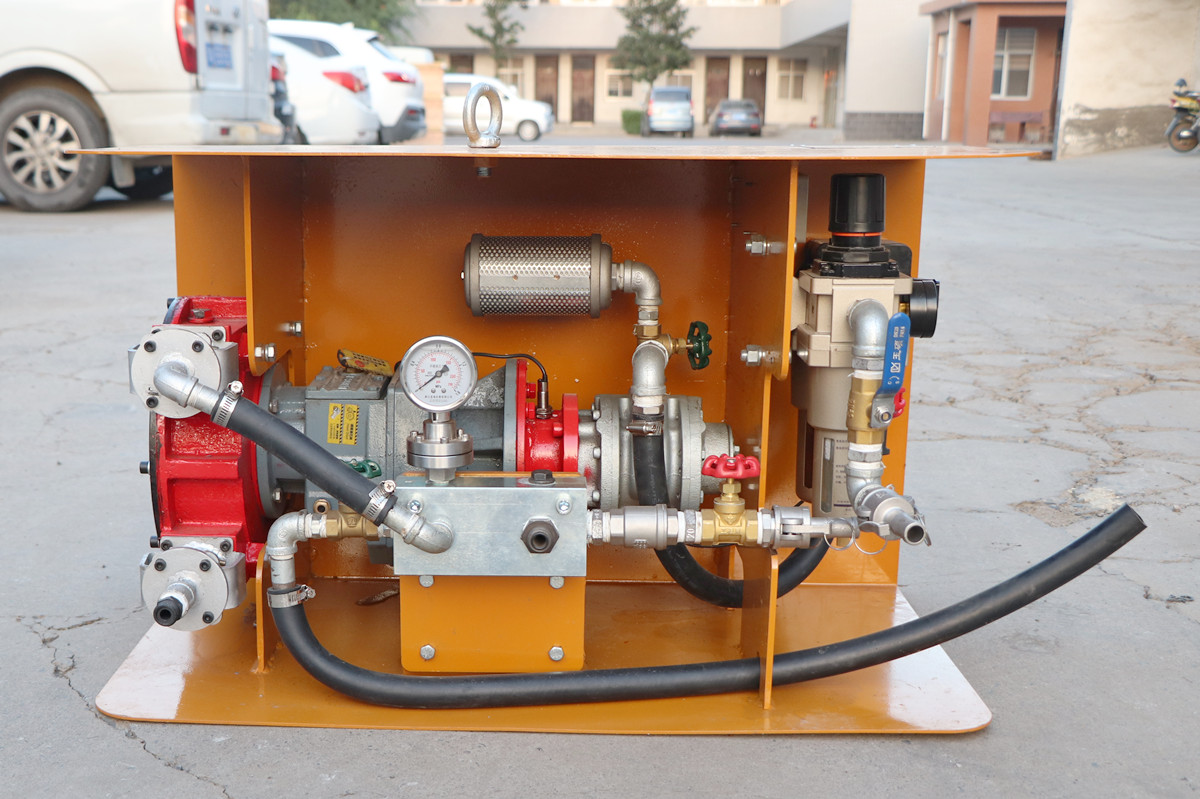

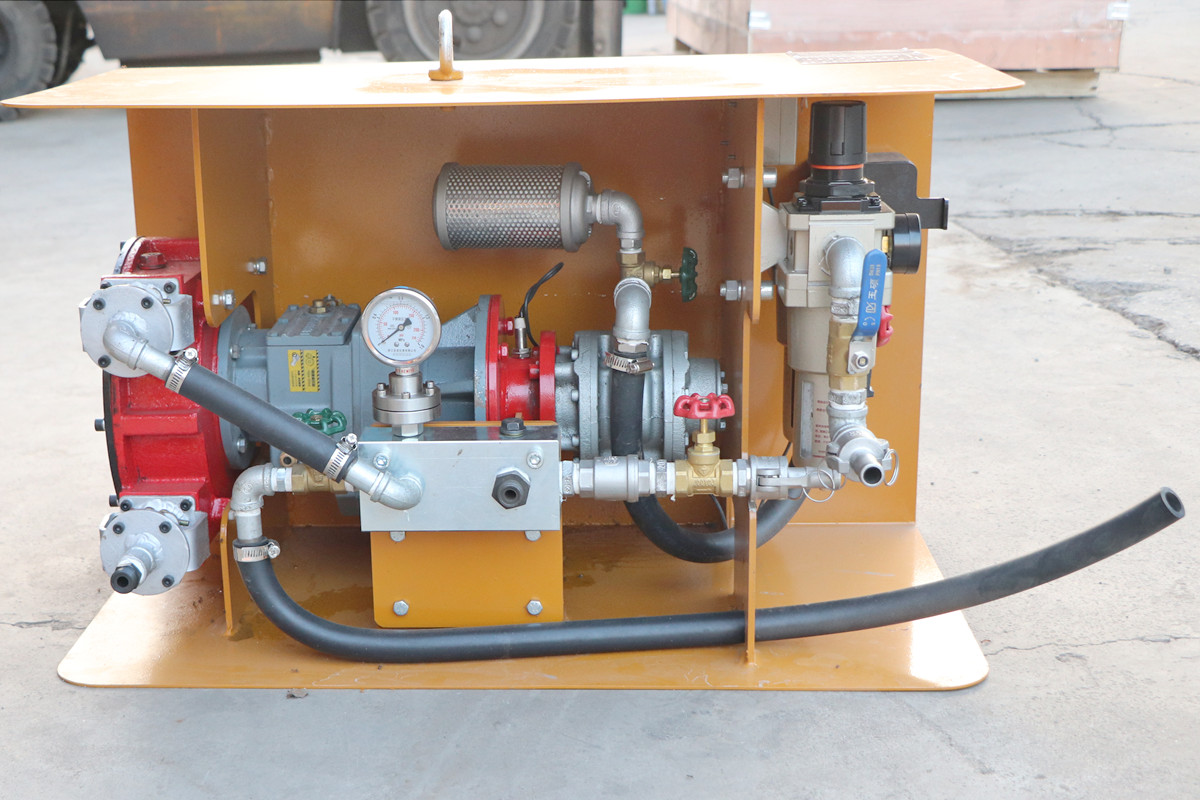

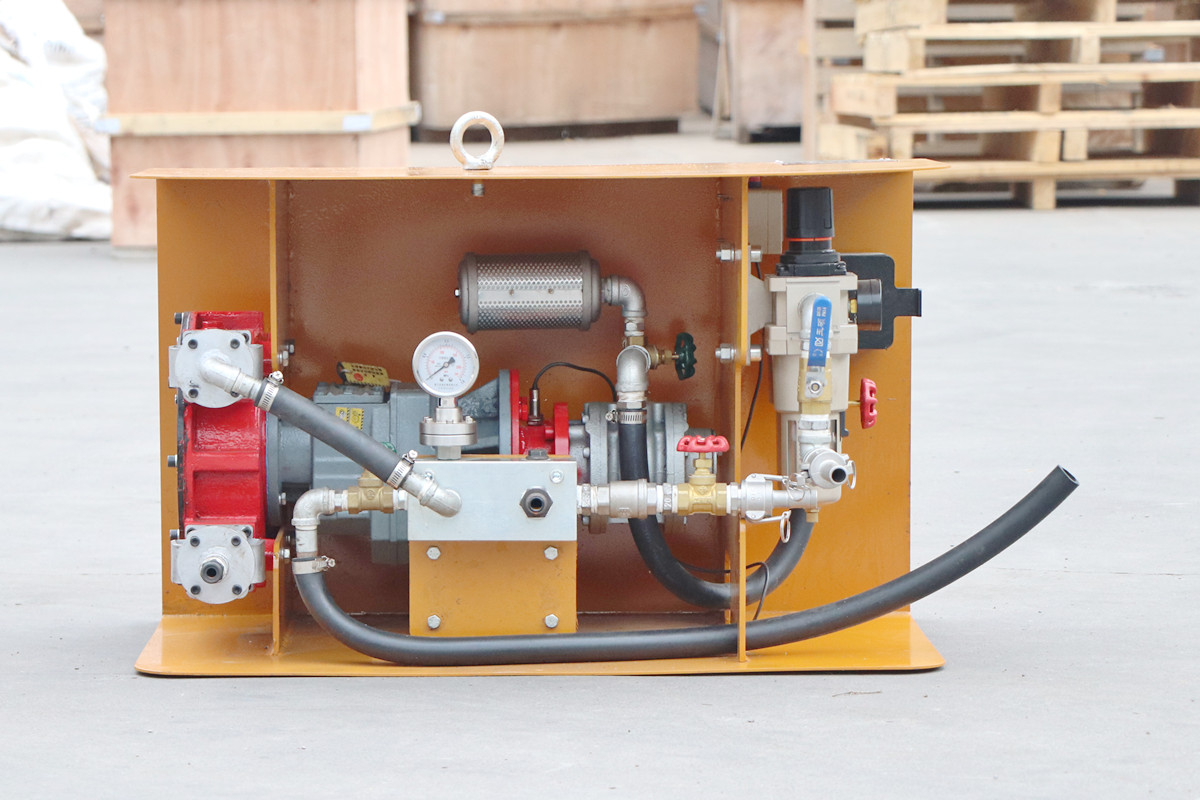

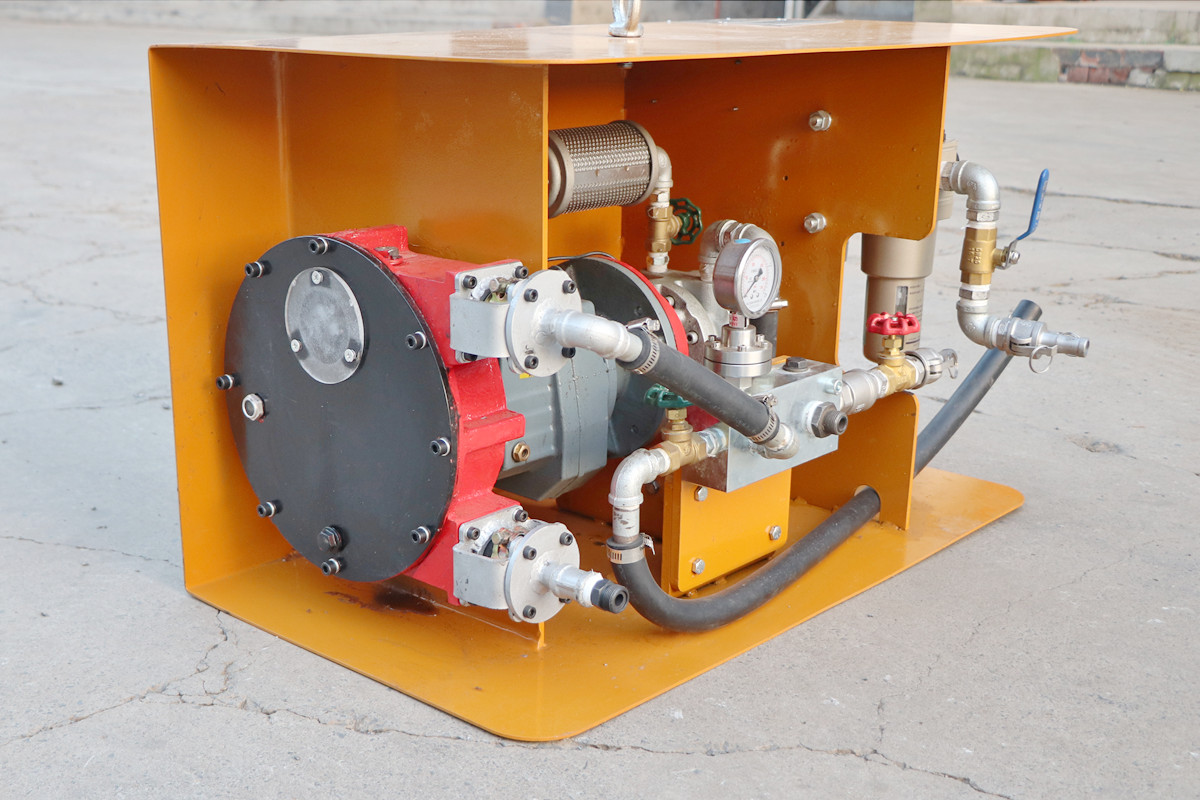

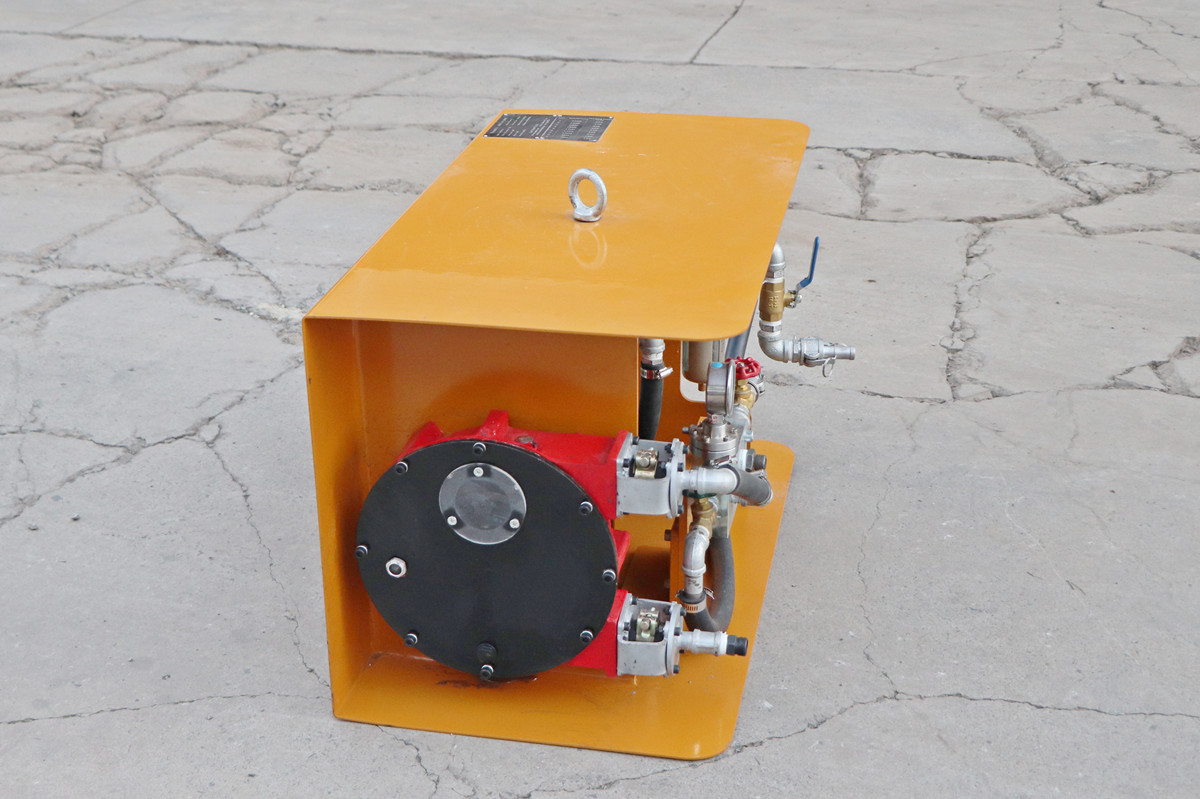

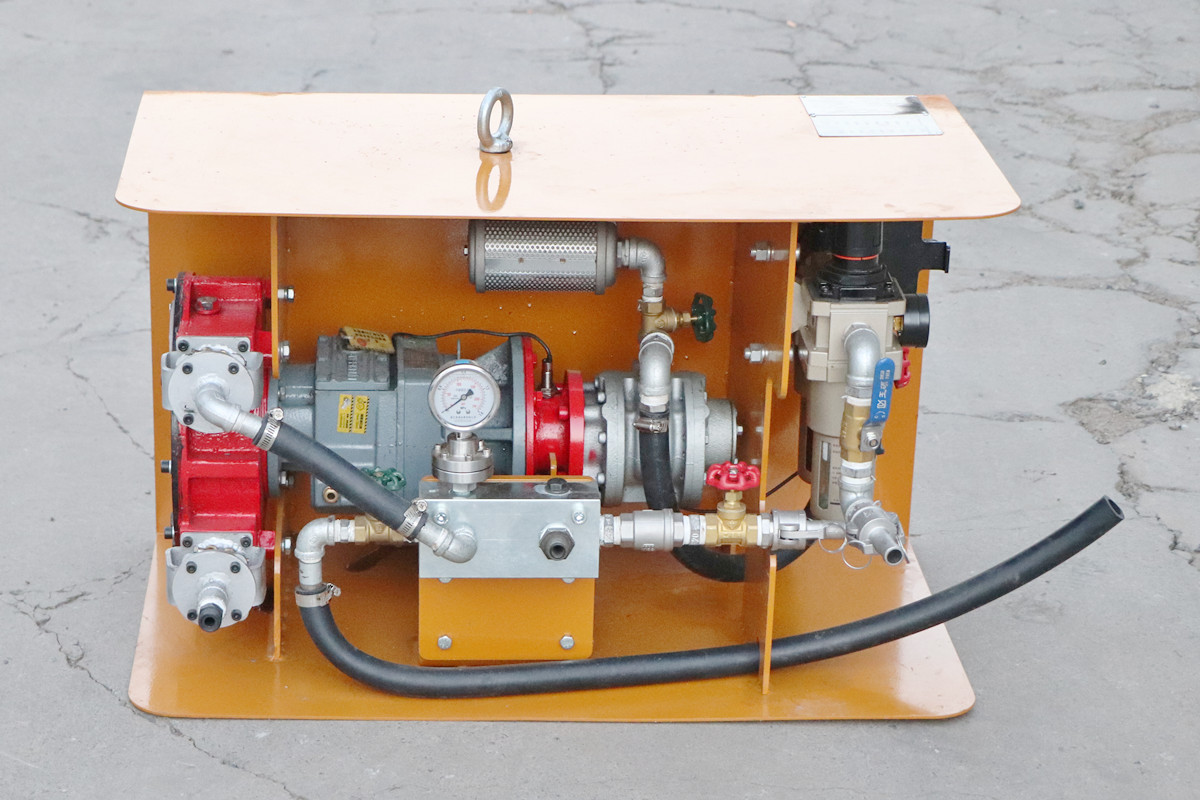

Concrete shotcrete machine for underground

Concrete shotcrete machine for underground is to transport the premixed dry materials (cement and aggregate) to the nozzle through a pneumatic conveying system, add water to the nozzle and then spray it out. This method is suitable for small-scale or temporary projects. In underground construction, shotcrete machines balance efficiency, safety, and adaptability. Their ability to rapidly apply durable concrete in challenging conditions makes them indispensable for modern tunneling and mining projects.

A concrete shotcrete machine designed for underground applications is a critical tool in tunneling, mining, and underground construction. It efficiently applies shotcrete (sprayed concrete) to stabilize rock faces, create waterproof linings, or provide structural support.

Underground Applications of Shotcrete Machine:

Tunneling & Mining:

Ground Support: Fiberglass or steel fiber-reinforced shotcrete for rock reinforcement.

Waterproofing: Dense, low-permeability mixes to seal tunnels.

Ventilation Ducts: Spraying concrete for ductwork or emergency exits.

Subway & Utility Construction:

Station Linings: Fire-resistant, decorative shotcrete finishes.

Cable/Pipe Galleries: Rapid installation of protective concrete layers.

Emergency Repair:

Stabilizing collapsed sections or sealing leaks in underground infrastructure.