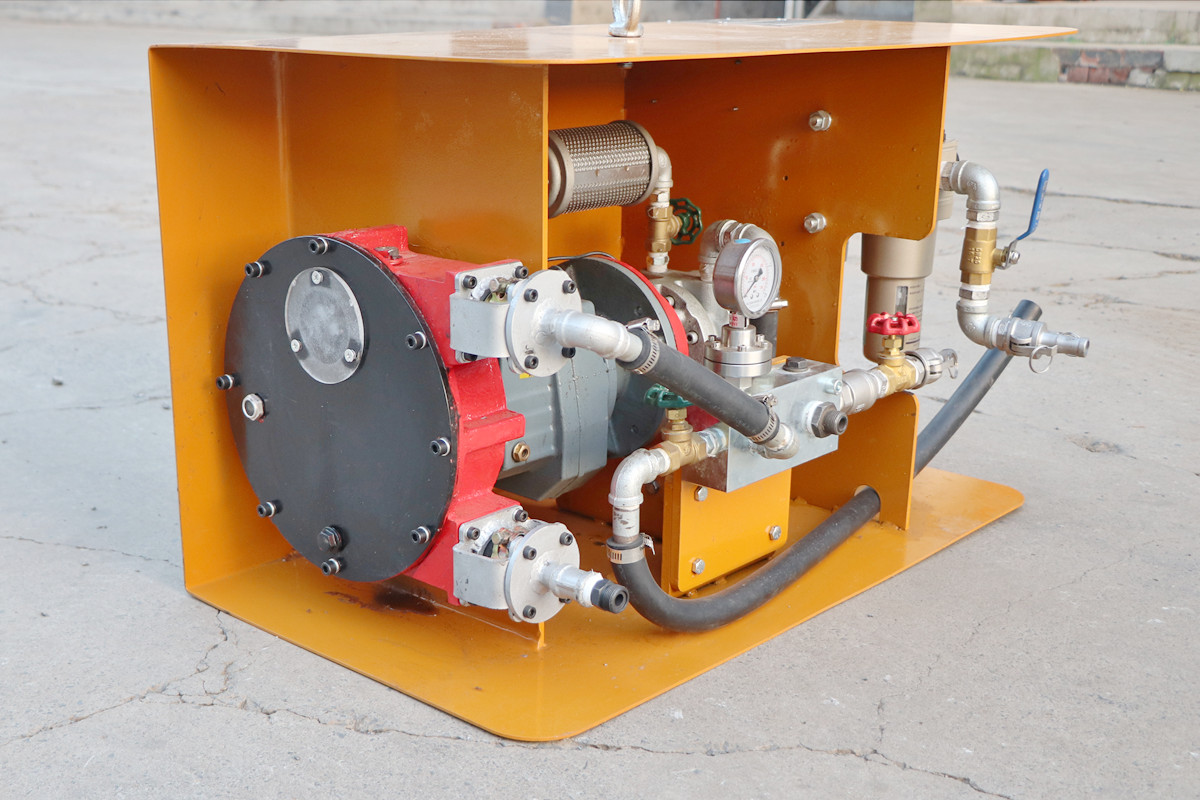

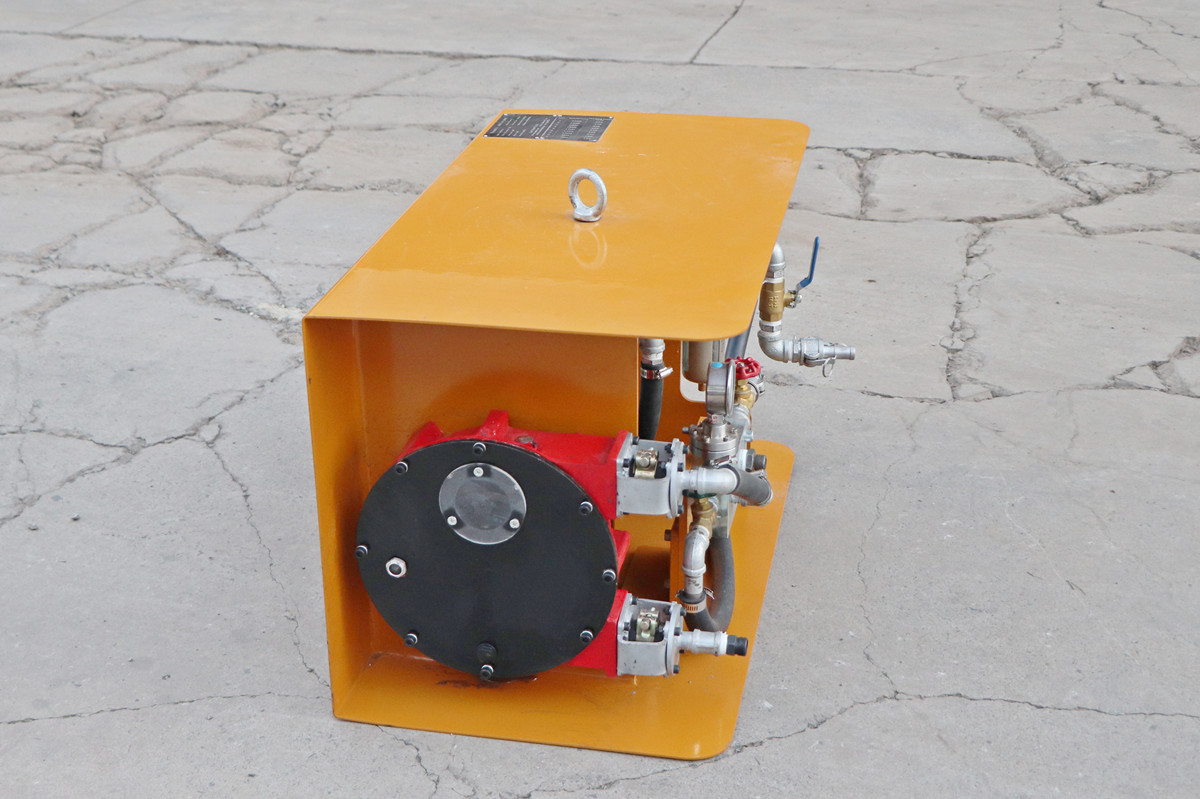

Concrete shotcrete machine for sale

There are many types of concrete shotcrete machines on sale. These devices are mainly used to continuously transport concrete along pipes and spray it onto the construction surface. They are widely used in shotcrete construction operations in underground projects, hydropower projects, shafts, tunnels, culverts and other fields.

Concrete Shotcrete Machine, also known as concrete spraying machine or concrete spraying machine, is a machine that uses compressed air to continuously transport concrete along the pipeline and spray it onto the construction surface. The following is a detailed introduction to concrete spraying machines:

1. Classification of concrete shotcrete machine for sale:

Concrete spraying machines are mainly classified according to the water adding method and structural type of concrete mixture. Common types include:

Dry spraying machine:

Features: It uses pre-mixed cement and aggregates, which are mixed with water in the pressure water tank by compressed air and then sprayed out.

Advantages and disadvantages: The construction is fast, but there are disadvantages such as large dust, high rebound loss and the need to use high-grade cement.

Wet spraying machine:

Features: It directly receives the concrete that has been added with water, which can reduce dust and rebound.

Advantages and disadvantages: Wet materials are easy to condense in the material pipeline to form blockages, which are difficult to clean, so their application is limited.

Semi-wet (wet) spraying machine:

Features: It is between dry and wet, and the moisture content of concrete mixture is 5%~8%.

Advantages and disadvantages: It can reduce dust, has low adhesion, is not easy to clog, and is an improved method for both dry and wet.

Cylinder-type spraying machine:

Features: The structure is sturdy and durable, but the body is heavy, the operation is complicated, and the pipe is easy to clog.

Advantages and disadvantages: It has been gradually eliminated.

Spiral spraying machine:

Features: Simple structure, small size, easy to move.

Advantages and disadvantages: It is easy to return air when the conveying distance is long, and it is suitable for spraying support of small tunnels.

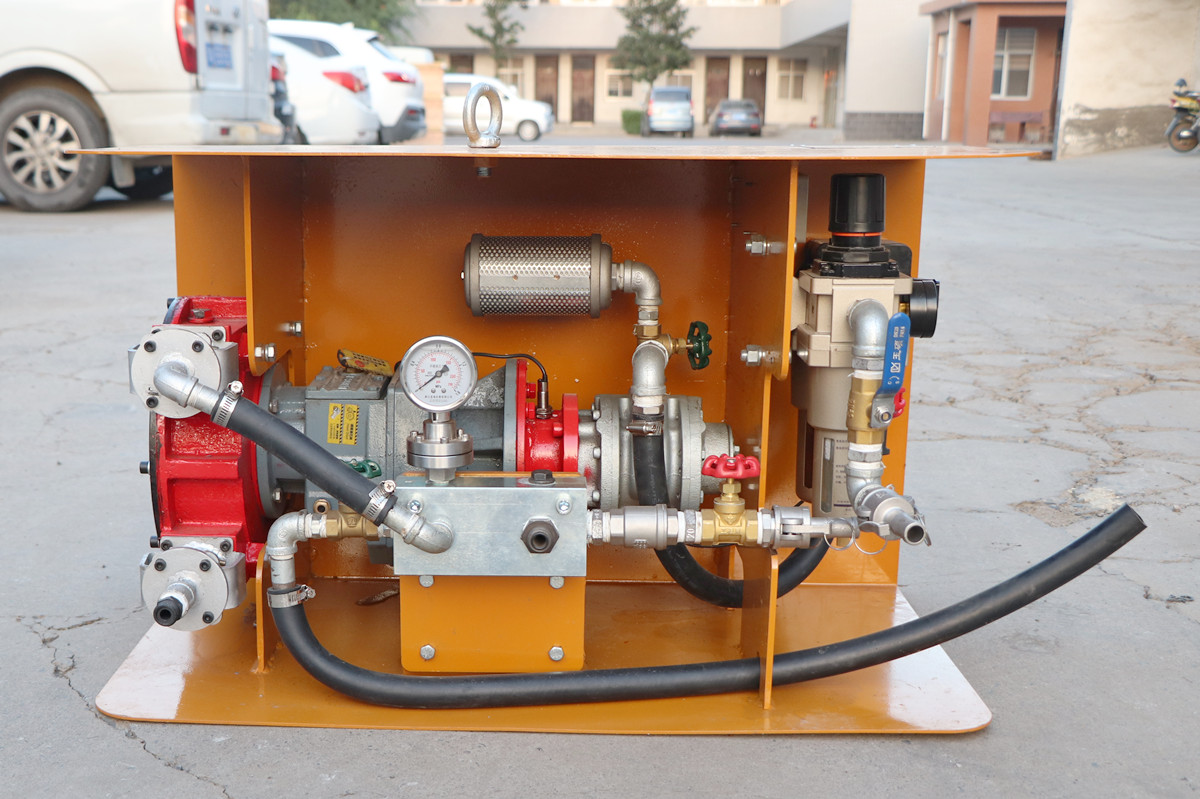

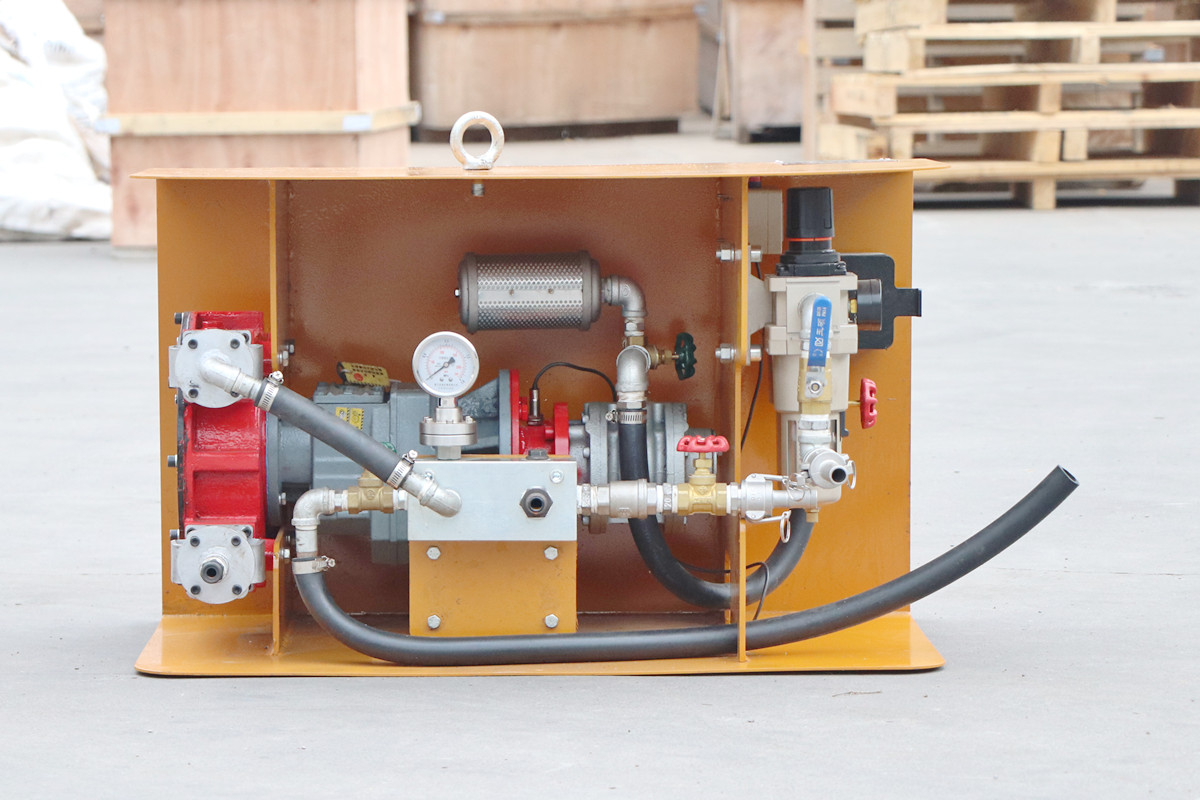

Rotor-type spraying machine:

Features: It has the advantages of large production capacity, long conveying distance, stable discharge and simple operation.

Advantages and disadvantages: It is suitable for a variety of spraying methods and is a widely used model at present.

2. Working principle of concrete spraying machine for sale:

Taking the rotor-type wet spraying machine as an example, its working principle is as follows:

The motor drives the reducer through the coupling, and the conveying shaft of the reducer drives the rotor to rotate.

The rotor drives the feeder on the hopper to rotate, and the concrete mixture falls into the rotating rotor material cavity through the hopper.

After the rotor rotates a certain angle, the compressed air is connected to the air inlet of the material cavity.

Under the action of compressed air, the material is sent into the nozzle through the discharge rotor and the feed pipe, and water is added to the nozzle and sprayed out.

3. Application field

Concrete spraying machine is widely used in lining construction and anchor spraying support operations of underground projects, shafts, tunnels, culverts, subways, hydropower projects, mines, high marshes, mine shafts, etc.

Concrete spraying machine is one of the indispensable and important equipment in construction projects.