Home » Planetary concrete mixer » concrete planetary mixer for prefabricated parts

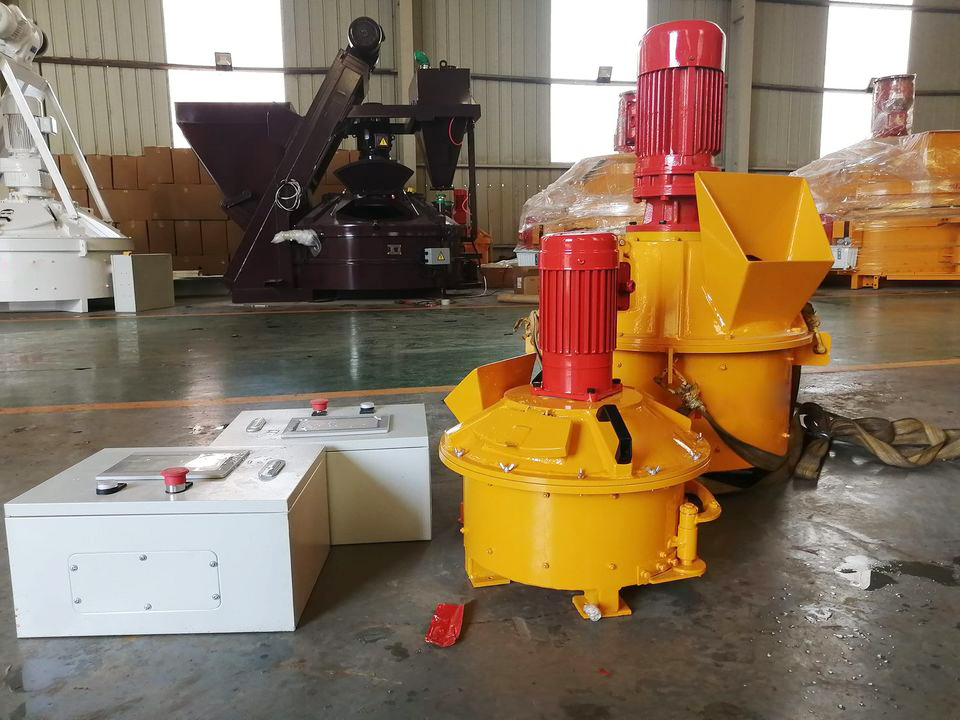

concrete planetary mixer for prefabricated parts

The concrete planetary mixer for prefabricated parts has a compact design, minimal running wear, no dead angle in mixing, no material sticking to the wall, and easy cleaning.

Contact Us

Get Price

Share:

Content 2022-05-13

The concrete planetary mixer for prefabricated parts is designed with a unique drive plate, installed with a stirring device and a scraper tool, and a vertical cylinder body is designed according to the operating space of the stirring tool. The mixing effect obtained by comparing consumption is better than that of general mixer equipment.

Inquiry

More Planetary concrete mixer