Home » Planetary concrete mixer » Concrete mixer planetary

Concrete mixer planetary

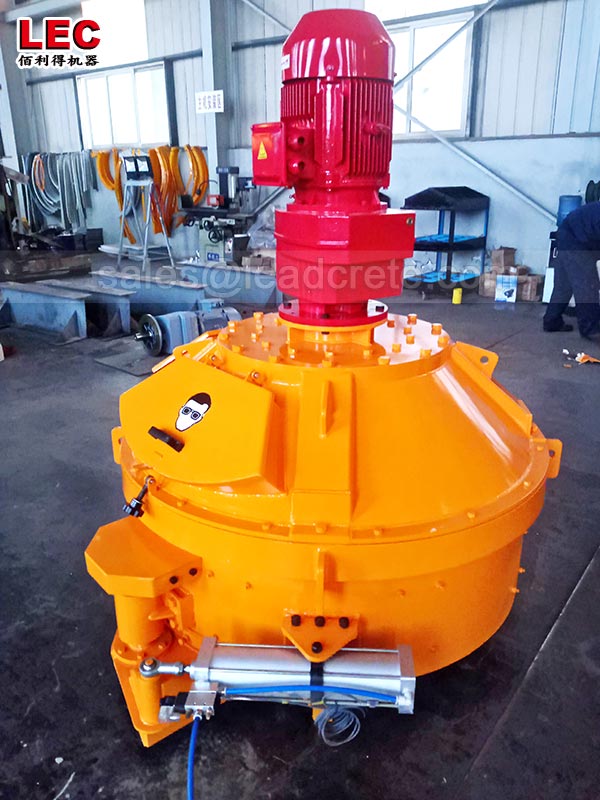

The Concrete mixer planetary uses a set of advanced motors and reducers to form a planetary revolution and rotation. This mixing method is combined with the side scraper installed in the mixing drum.

Contact Us

Get Price

Share:

Previous:

Concrete mixer 500 litre

Next:

Cement mortar mixer

Content 2021-12-21

In order to buy a high-quality concrete mixer planetary, we need to have certain skills, in order to help us avoid misunderstandings, and buy a high-quality refractory mixer to improve production and construction quality and ensure production efficiency.

As the mixing technology of the concrete mixer planetary is continuously improved, the mixing uniformity of the mixer is also increased, and the application industry is more extensive. Concrete mixer planetary has complete models and specifications. You are welcome to call us.

Inquiry

More Planetary concrete mixer