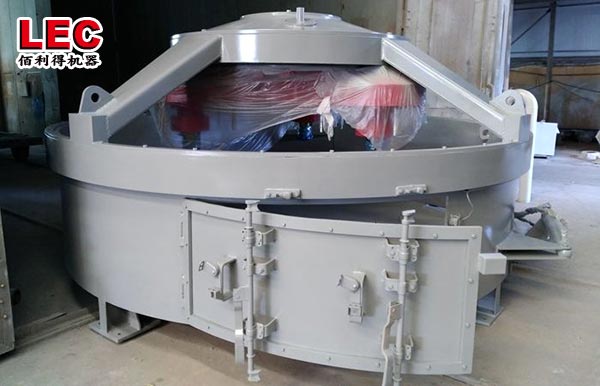

Competitive price planetary mixer

The application of FRP competitive price planetary mixer meets the technical requirements of the industry. The whole is sturdy and durable, and the operation is more stable. In addition to mixing FRP concrete, it can also be used in various fields such as refractory material industry, brick making machine production line, solid waste treatment and so on. A single stirring can achieve a homogeneous effect, easily solve the problems of shaft holding and uneven stirring during the stirring and stirring process, and bring a better experience to the stirring process.

Competitive price planetary mixer can also be used in PC prefabricated component production line, pccp prestressed pipe, square culvert, pipe pile, subway segment, ready-mixed concrete production line, foamed concrete production line, lightweight wallboard production line, mortar wallboard production line, hydraulic engineering block brick production line, concrete brick production line, pavement brick production line, grey brick, permeable brick production line, etc.