Compact concrete spraying machine for dry-shotcrete

Compact concrete spraying machines for dry-shotcrete are specialized equipment used in the construction industry for applying dry-shotcrete mixtures. These machines are designed to efficiently spray concrete mixtures that have a low water-cement ratio (typically less than 0.25), making them suitable for a variety of applications where high-strength and durable concrete surfaces are required.

Applications of compact concrete spraying machine for dry-shotcrete:

Compact concrete spraying machines for dry-shotcrete are commonly used in a variety of construction applications, including:

Tunneling and mining

Slope stabilization

Underground construction

Repair and rehabilitation of existing structures

Building and construction of new structures where high-strength and durable concrete surfaces are required.

Price and Availability

The price of compact concrete spraying machines for dry-shotcrete can vary depending on factors such as brand, model, and features. These machines are typically available from specialized construction equipment suppliers or manufacturers. When purchasing a machine, it is important to consider factors such as the specific needs of the project, the size and scope of the job site, and the budget available.

Key features of compact concrete spraying machine for dry-shotcrete:

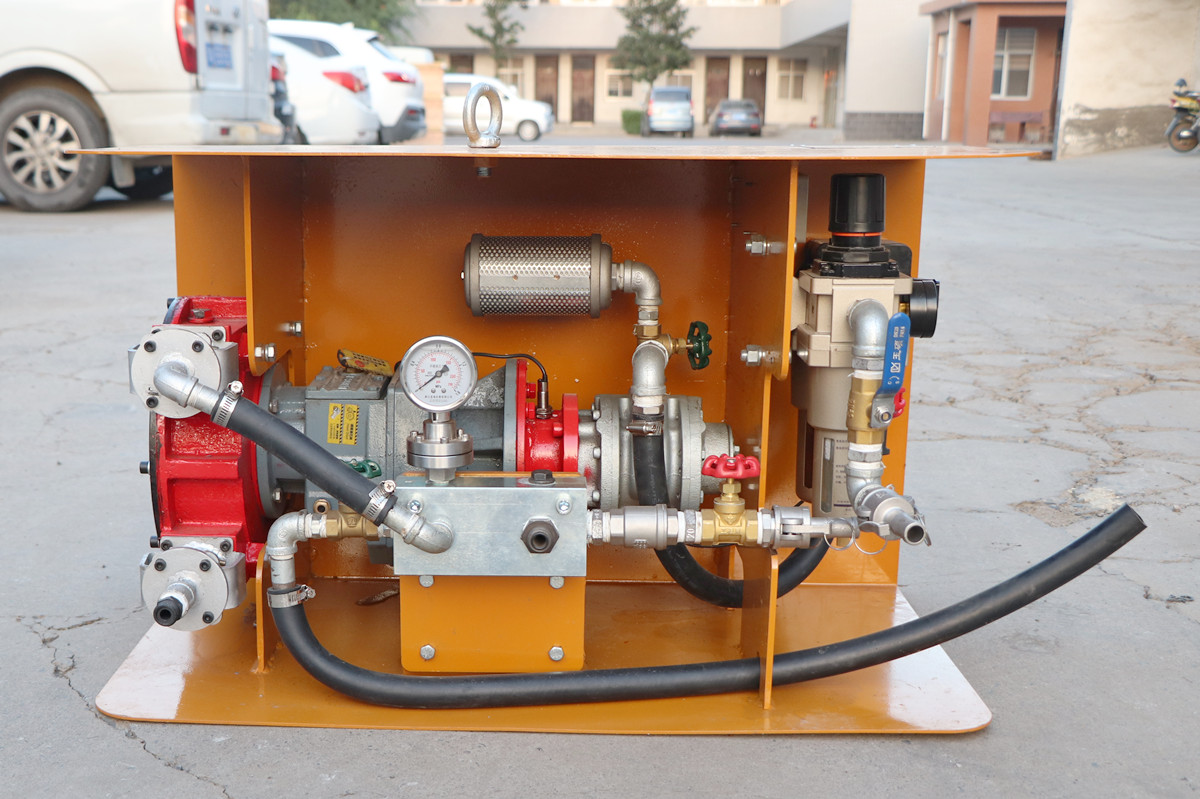

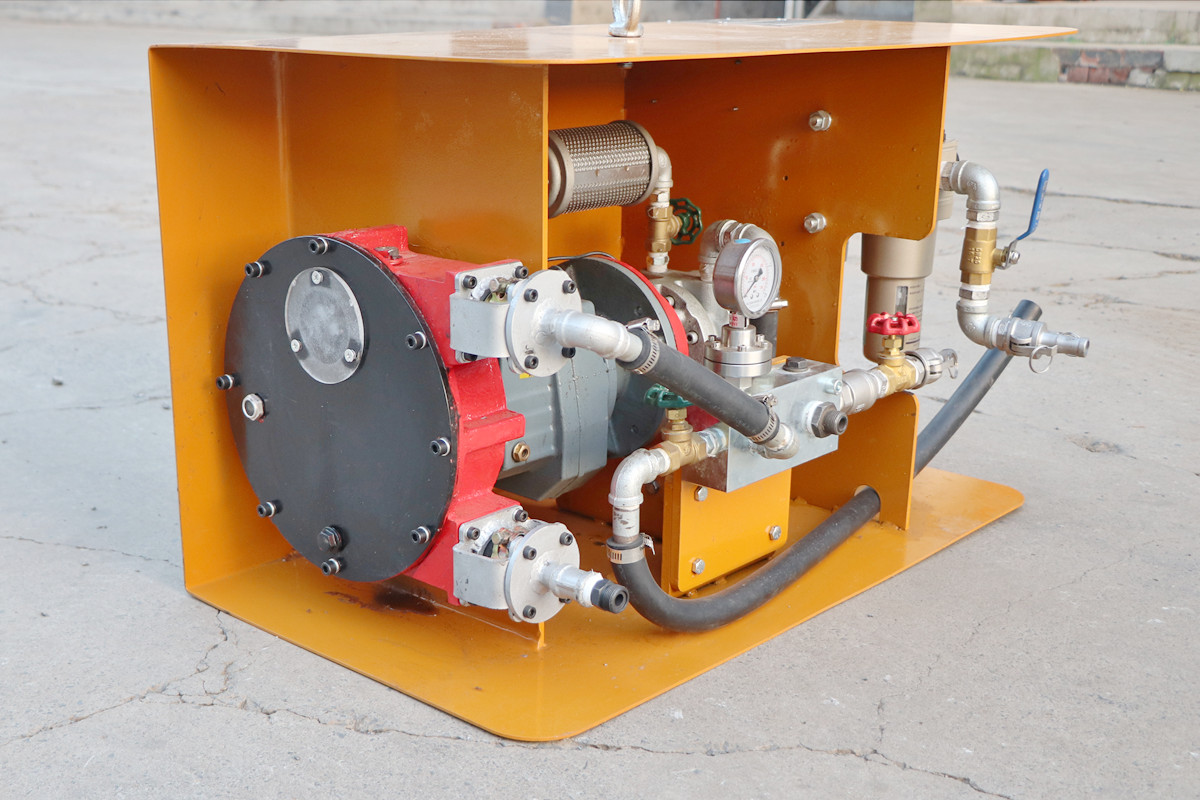

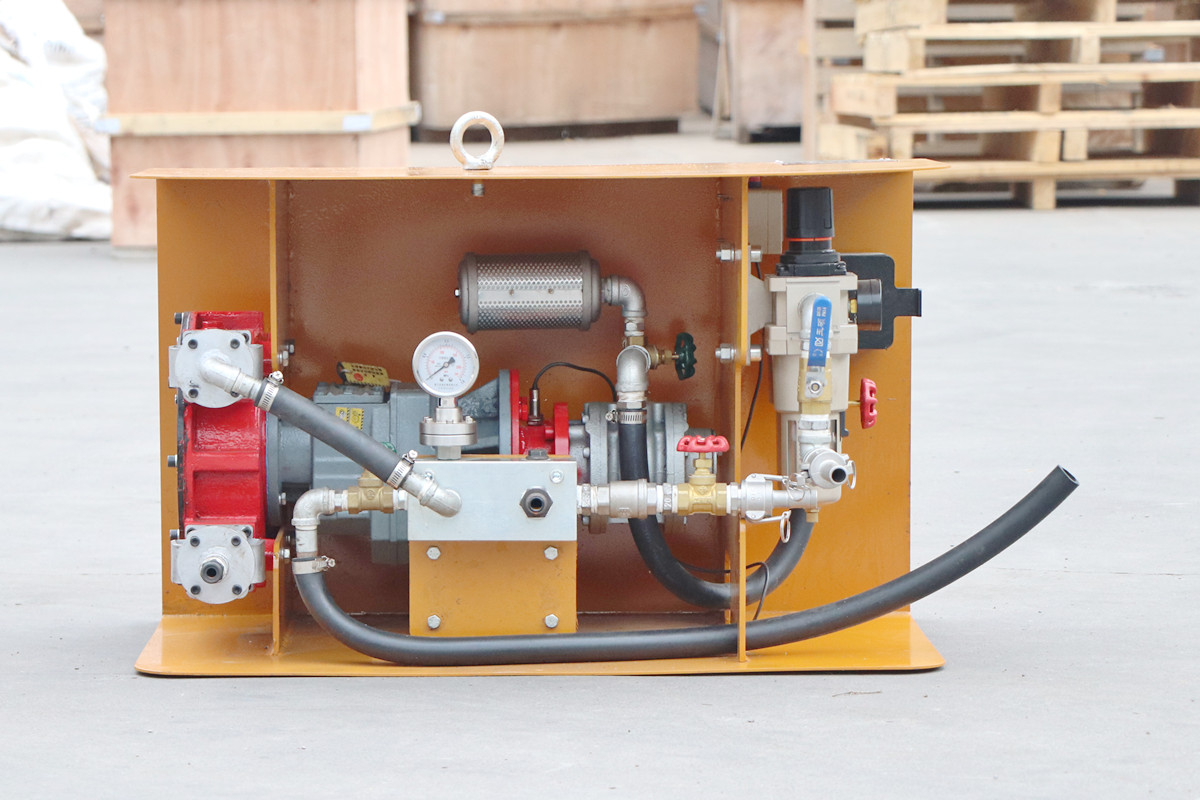

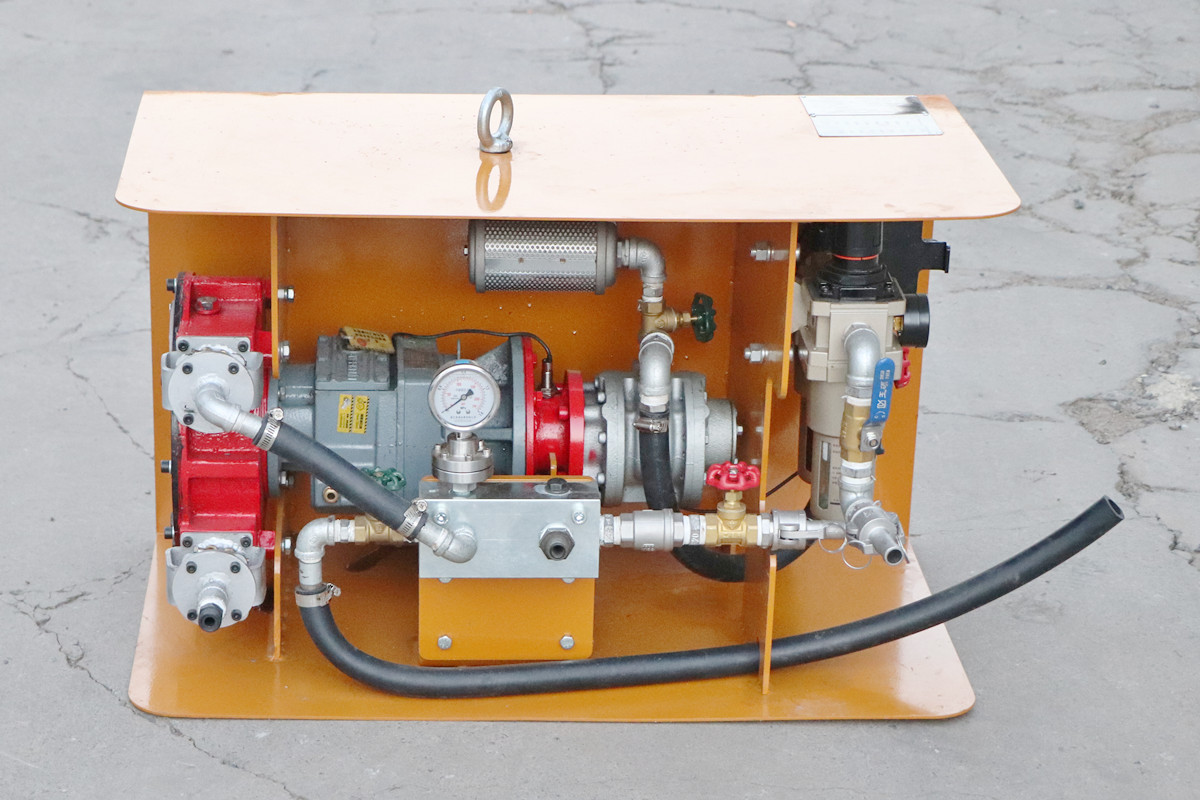

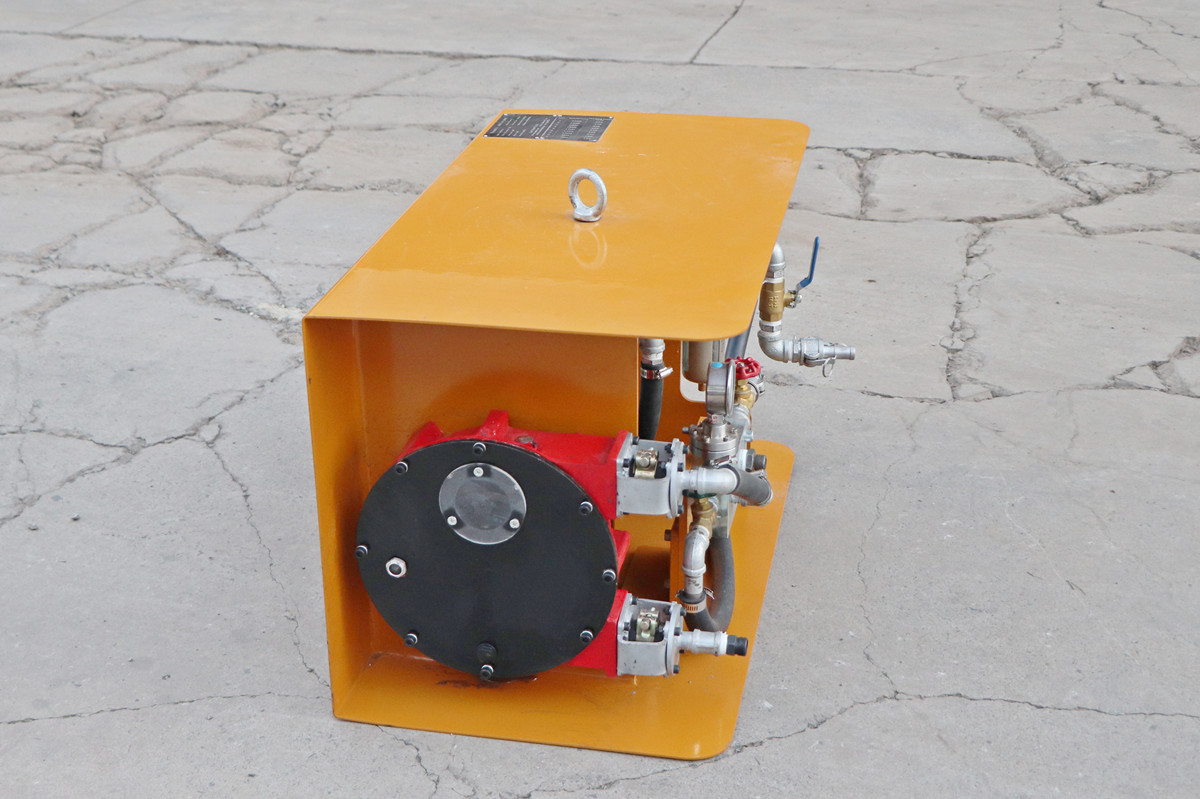

Compact Design:

These machines are typically designed to be compact and portable, allowing them to be easily transported to different job sites.

The compact design also helps in reducing the overall footprint of the equipment, making it easier to maneuver in tight spaces.

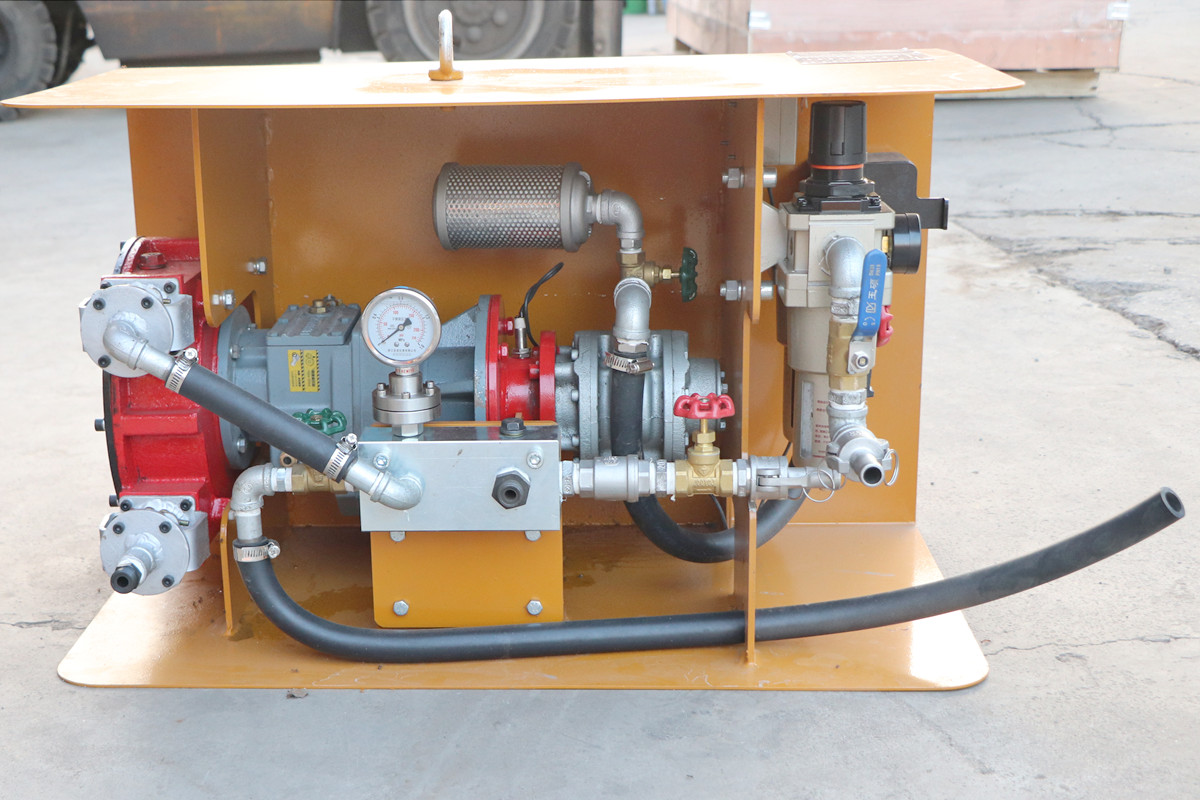

Efficient Spraying:

The machines use compressed air to transport the dry concrete mixture through a hose to the nozzle.

At the nozzle, water is added in a mist form to mix with the dry concrete, creating a shotcrete mixture that is then sprayed onto the desired surface.

Long Conveying Distance:

Many compact concrete spraying machines for dry-shotcrete have a long conveying distance, allowing them to reach areas that are difficult to access.

This feature is particularly useful in large-scale construction projects or in areas with limited access.

Adjustable Mixing Ratios:

The machines often come with adjustable mixing ratios, allowing operators to customize the water-cement ratio to meet specific project requirements.

This ensures that the final concrete surface has the desired strength and durability.

Dust Reduction:

Some models are equipped with dust collectors or other dust reduction technologies to minimize the amount of dust generated during the spraying process.

This helps in creating a safer and cleaner work environment for operators and other workers on the job site.