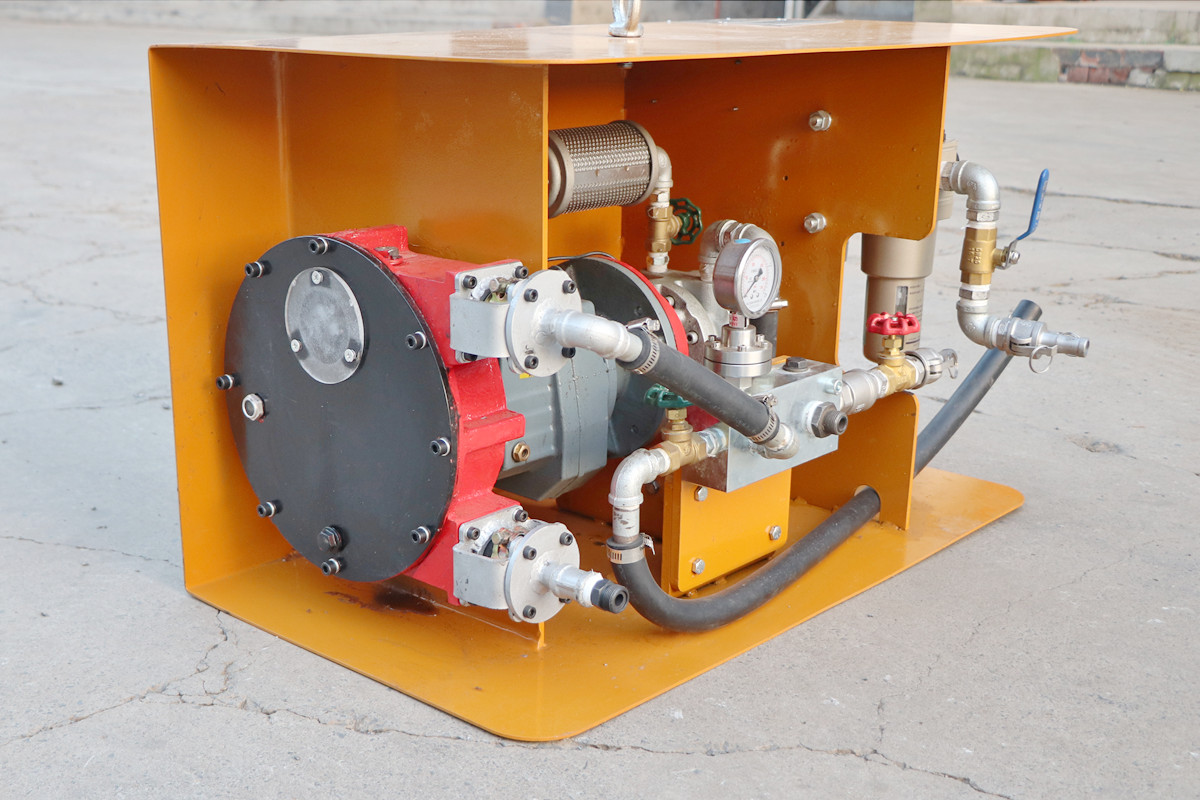

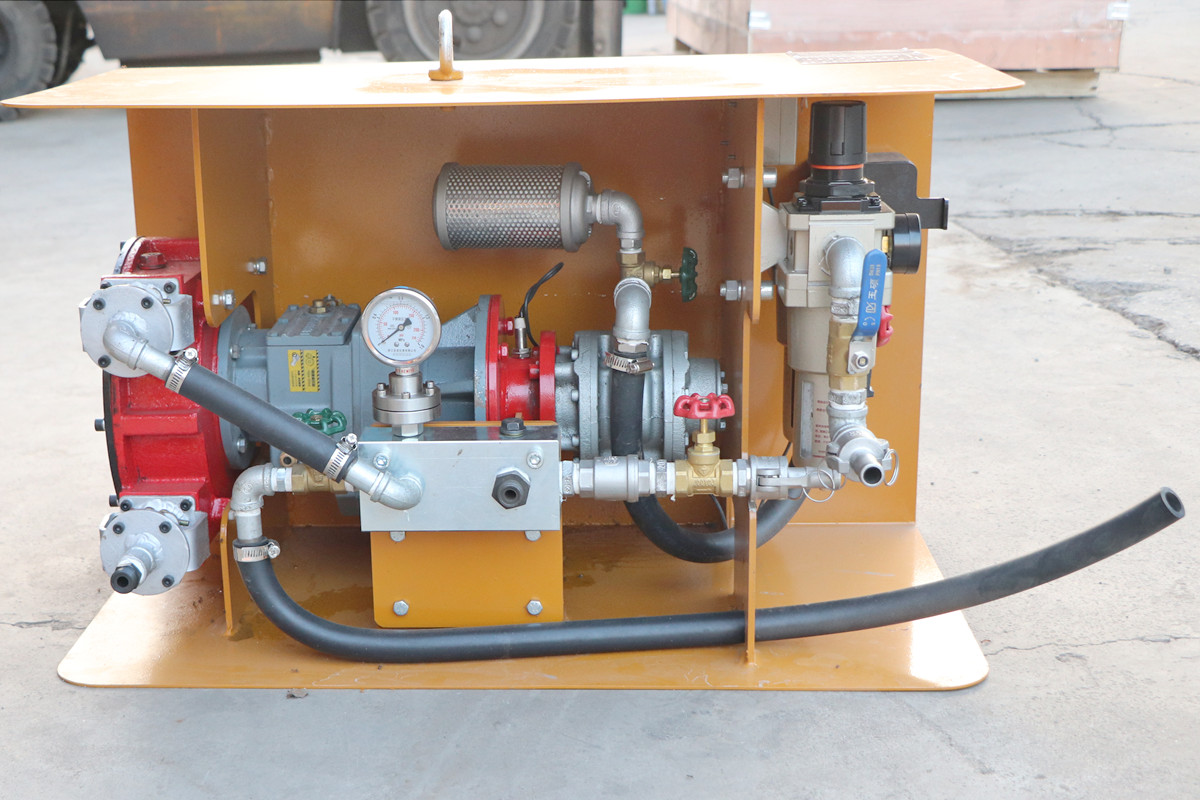

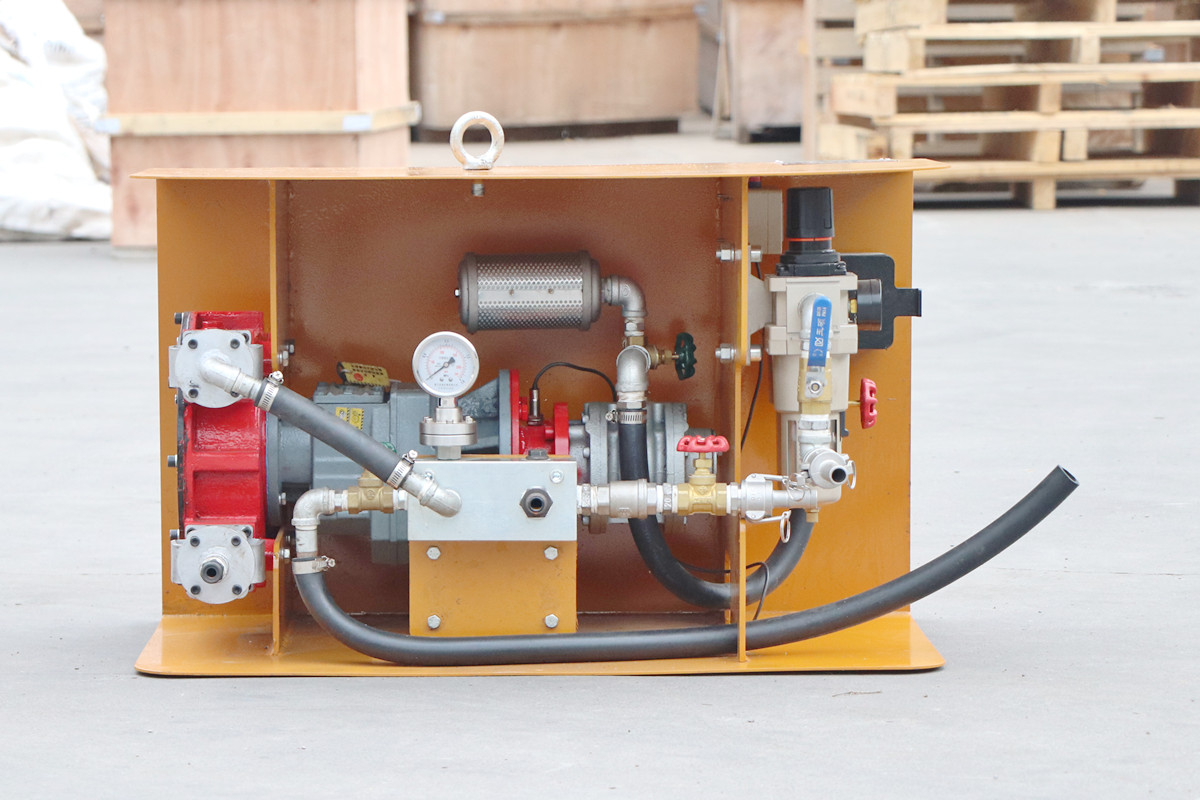

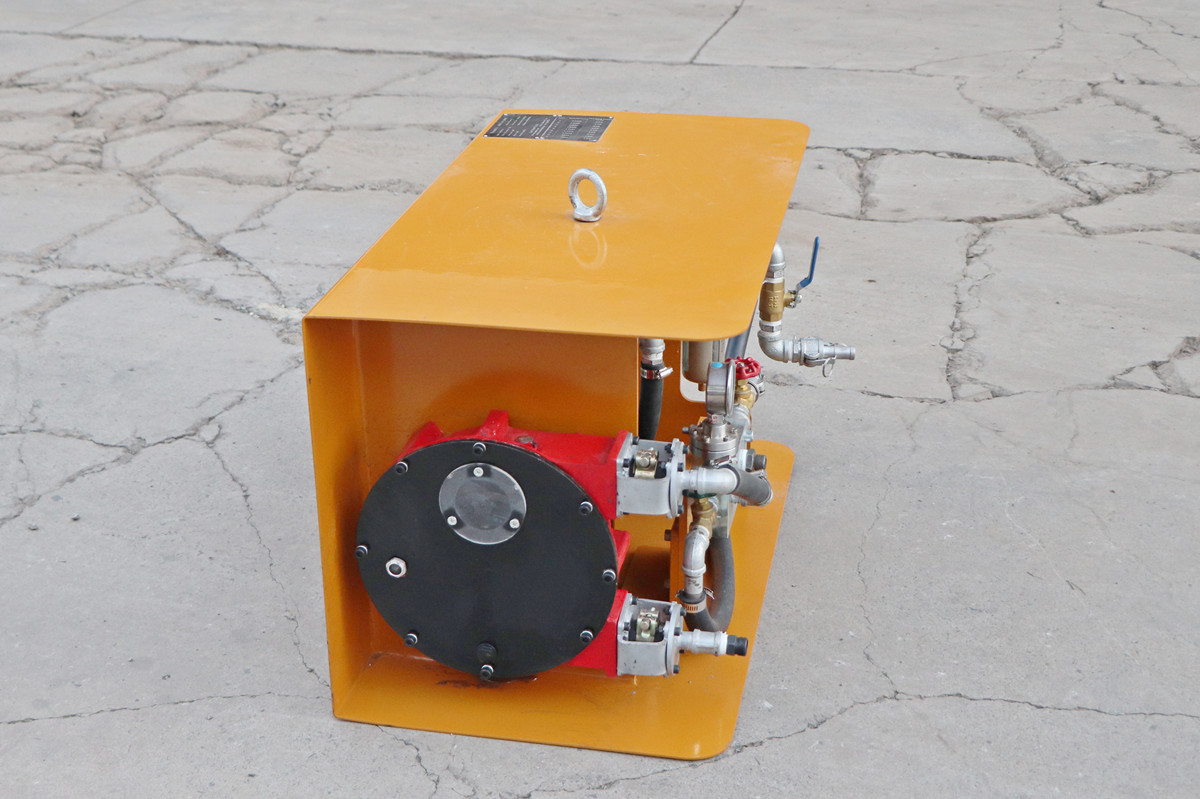

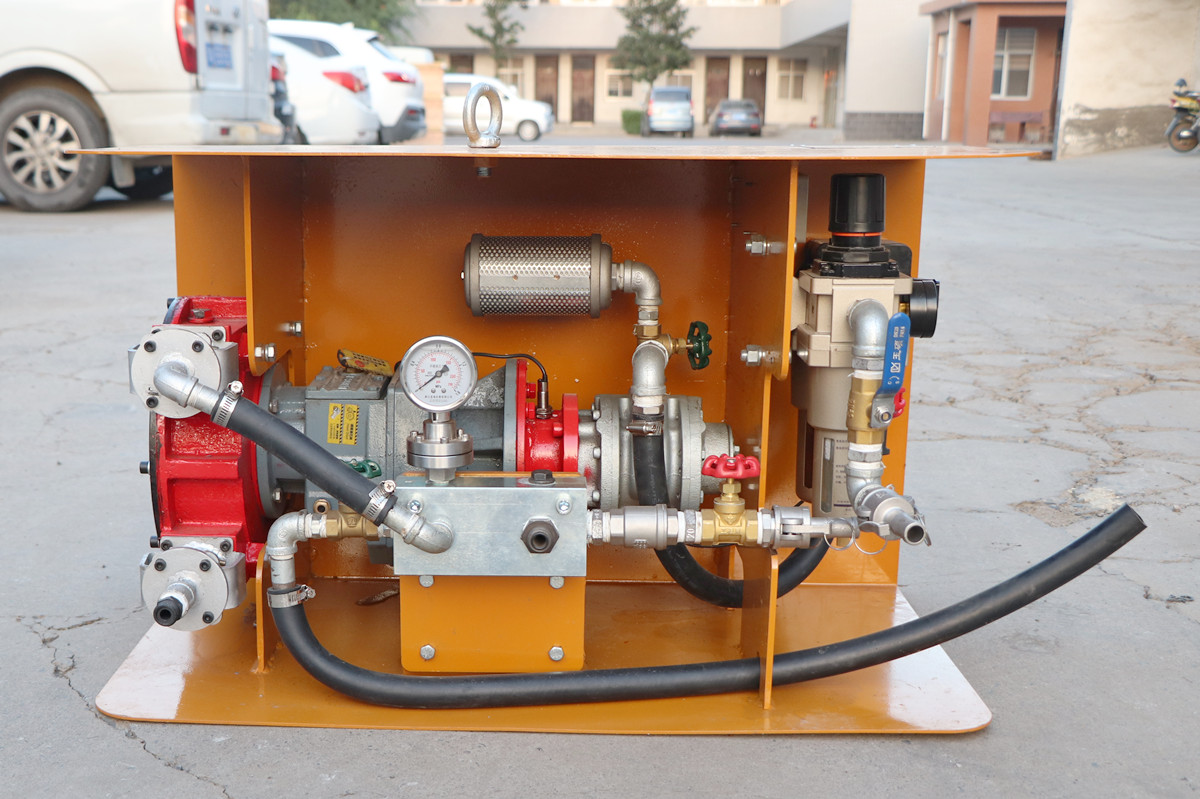

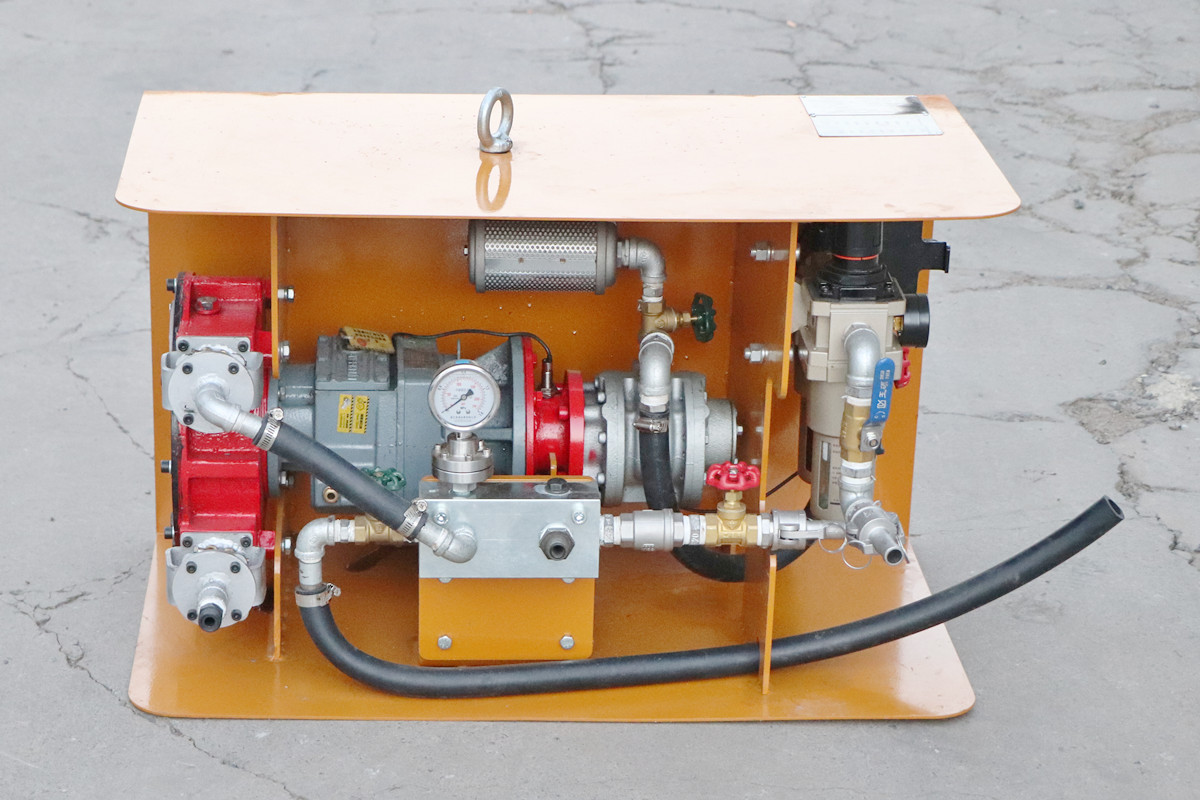

Air driven accelerator metering pump system

An air-driven accelerator metering pump system for shotcrete is specifically designed to meter and inject chemical accelerators into the shotcrete mix during the spraying process. This system uses compressed air as the driving force, making it ideal for environments where electrical systems may not be suitable or where compressed air is already available, such as in tunnels, underground mines, and other hazardous work environments. The accelerator, a key additive in shotcrete, helps to reduce setting time and increase early strength development, which is critical in high-pressure environments.

Key Features of an Air-Driven Accelerator Metering Pump System for Shotcrete:

Pneumatic Operation (Air-Driven):

Compressed Air Power: The pump operates using compressed air rather than electricity. This ensures a safer and more reliable operation in hazardous environments, such as tunnels, mining operations, and other areas where sparks or electrical equipment pose a risk.

No Electrical Power Needed: Being air-driven, the system is ideal for remote locations or areas where access to electrical power is limited or restricted due to safety concerns (e.g., explosive or flammable environments).

Accurate Metering and Dosing:

Precise Control: The air-driven pump provides accurate and consistent metering of the accelerator into the shotcrete mix. This is crucial to ensure the right amount of accelerator is added, achieving the desired rapid setting properties without affecting the quality of the concrete.

Adjustable Flow Rate: The system allows operators to easily adjust the flow rate of the accelerator to match the specific requirements of the shotcrete application, environmental conditions, and material being sprayed.

Corrosion-Resistant Materials:

Durable Construction: Components of the pump, such as the pump body, seals, and valves, are made from corrosion-resistant materials (e.g., stainless steel, polypropylene, or PVDF). This ensures the system can handle the often corrosive nature of chemical accelerators like alkali-free solutions, ensuring long-term durability and reliability.

Chemical Compatibility:

The air-driven system is designed to handle a variety of chemical accelerators, including those with high viscosity or corrosive properties. This compatibility allows the system to be flexible for different shotcrete applications, whether using alkali-free accelerators or other chemical additives.

High-Pressure Handling:

Pneumatic Diaphragm or Piston Pumps: These pumps are commonly used in air-driven systems due to their ability to handle high-pressure environments and maintain consistent flow. Diaphragm pumps are especially useful for handling viscous or abrasive fluids, which can be the case with certain accelerators.

Integrated with Shotcrete Machine:

The accelerator metering pump system is typically integrated with the shotcrete machine, synchronizing the accelerator injection with the concrete spray process. This ensures that the accelerator is added at the appropriate time and in the correct ratio to the shotcrete mix, optimizing the setting and curing process.

Pressure Regulation and Control:

The system is equipped with air pressure regulators to ensure that the appropriate air pressure is applied to the pump. This helps maintain consistent dosing and prevents over- or under-application of the accelerator, which could affect the quality and strength of the shotcrete.

Flow Meters and Gauges: These devices provide real-time monitoring of the accelerator flow rate, allowing operators to ensure that the correct amount of accelerator is being metered into the shotcrete mix.