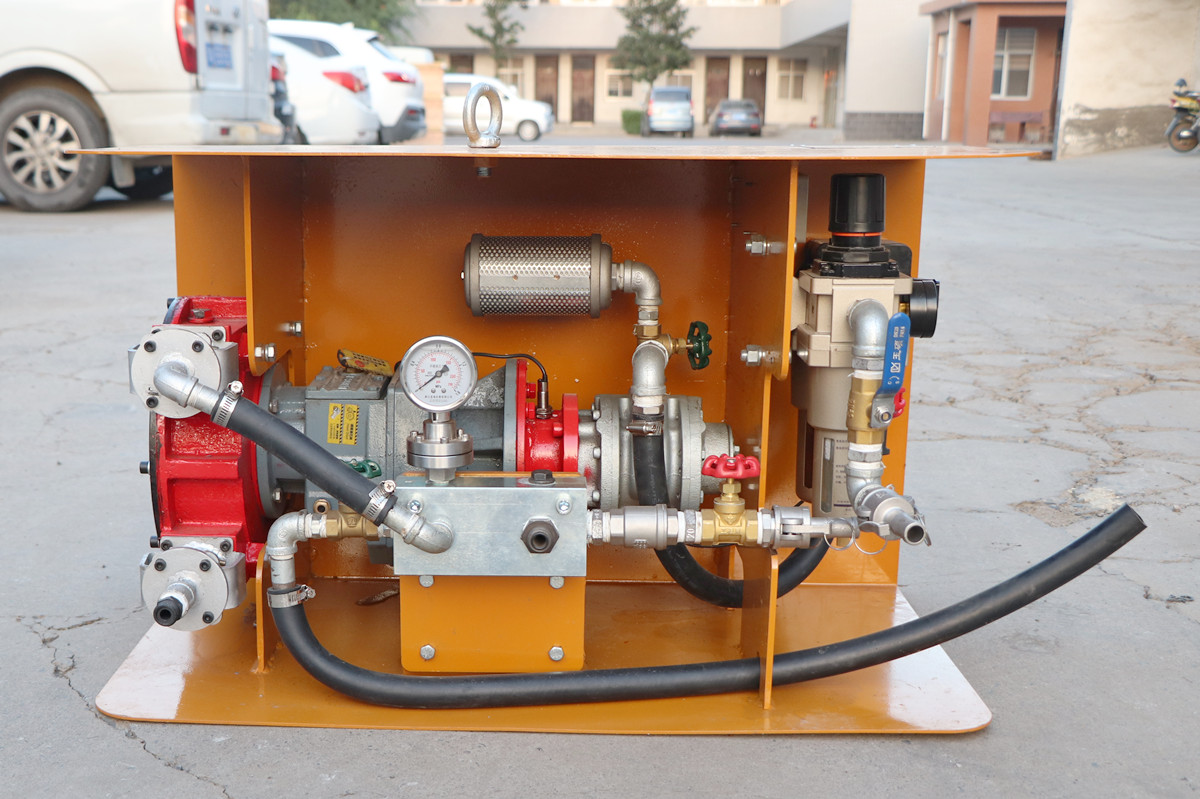

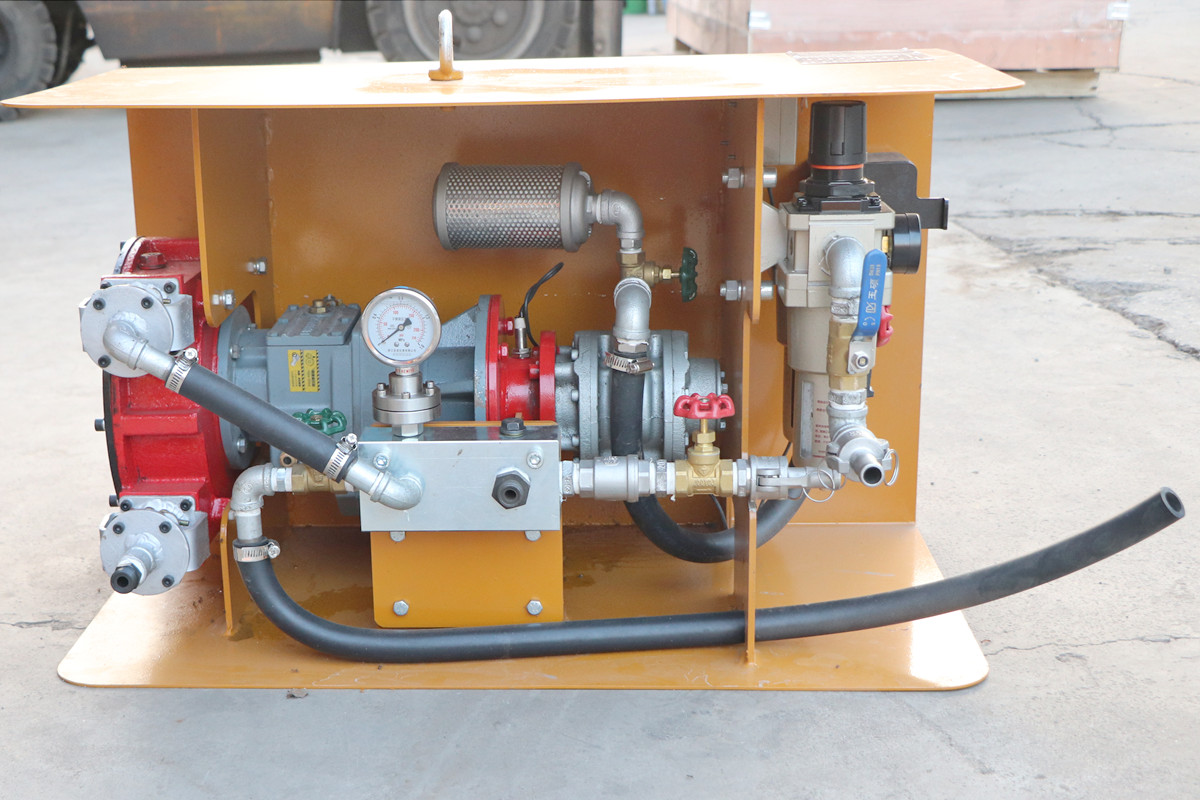

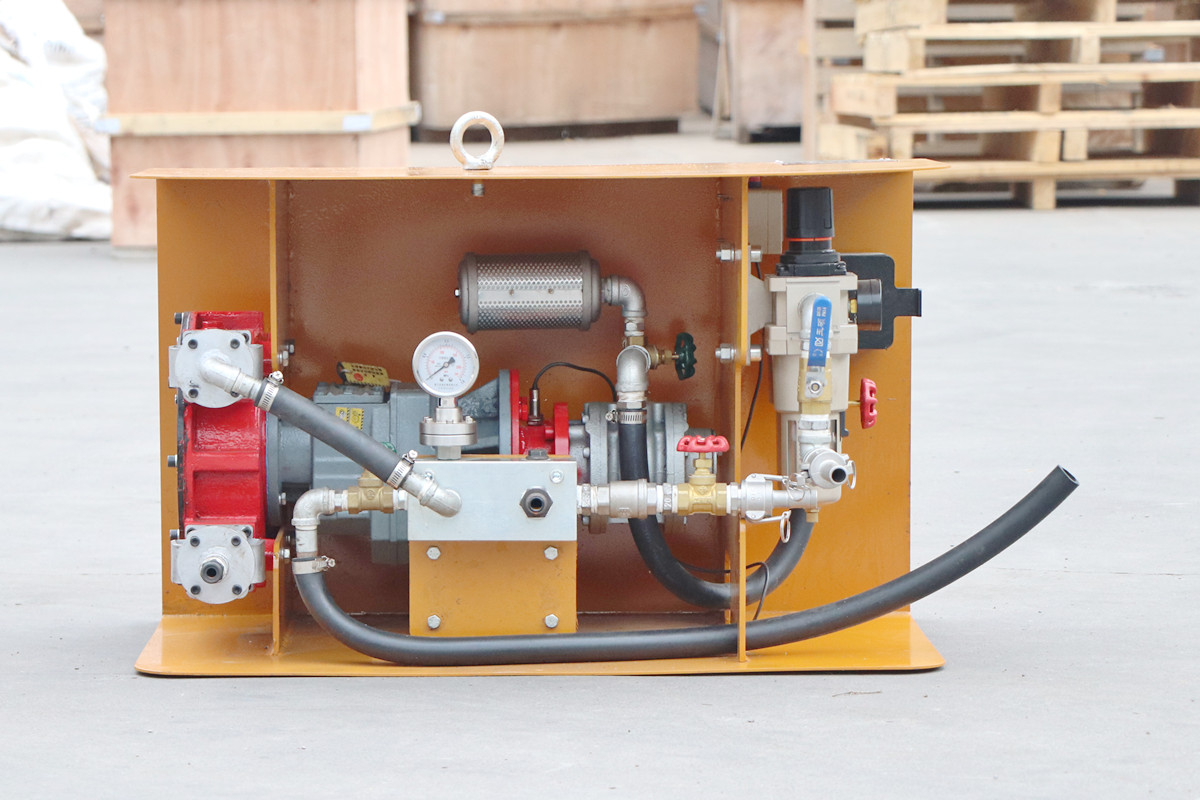

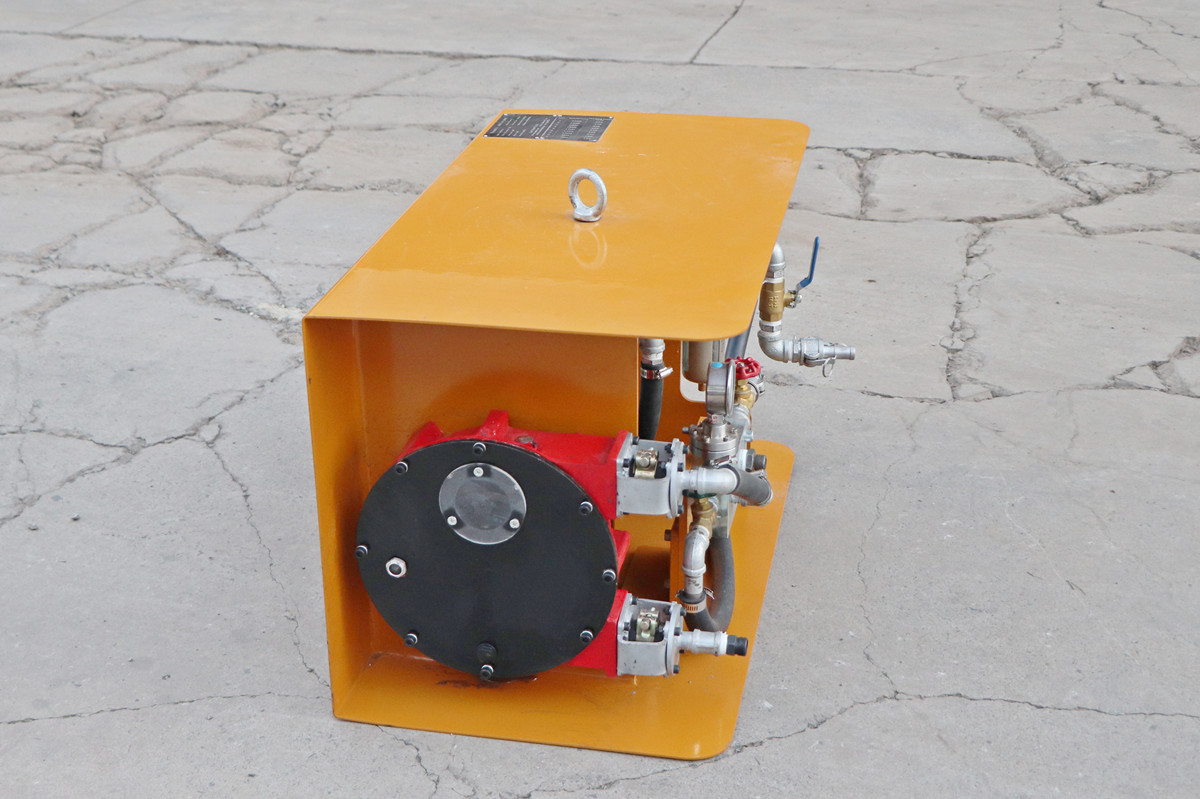

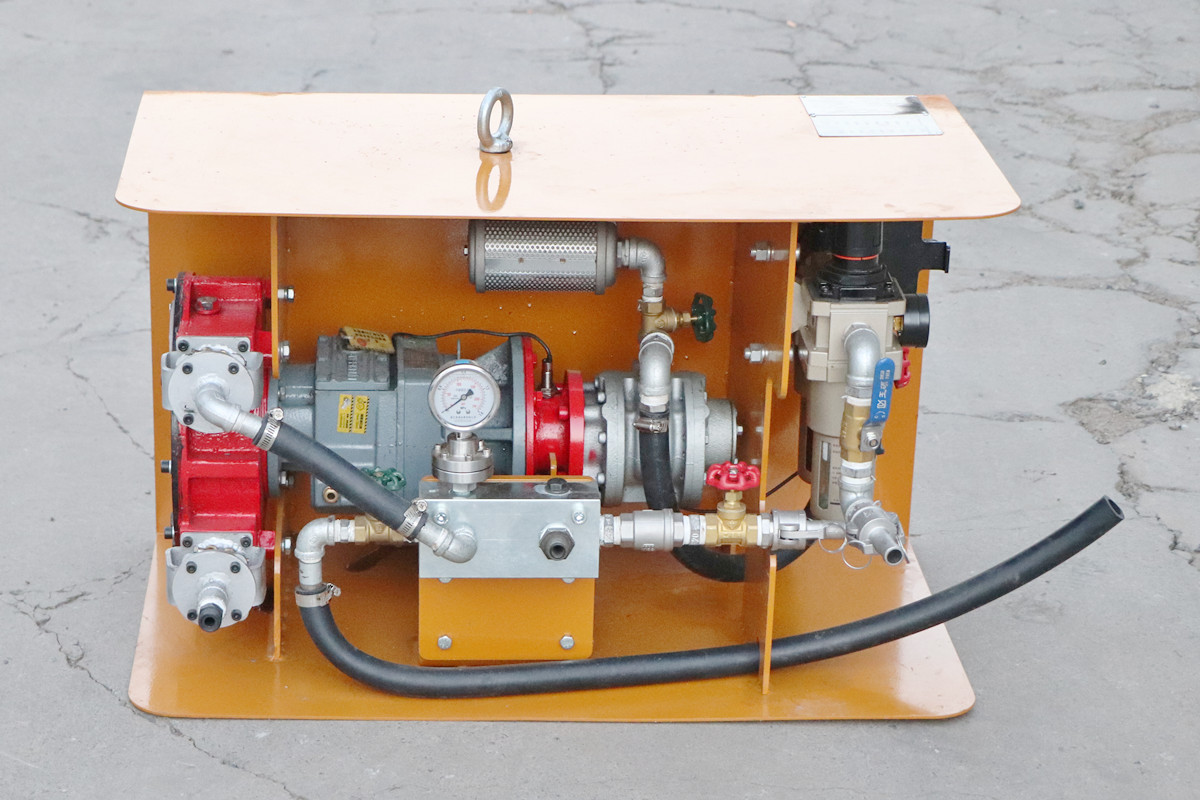

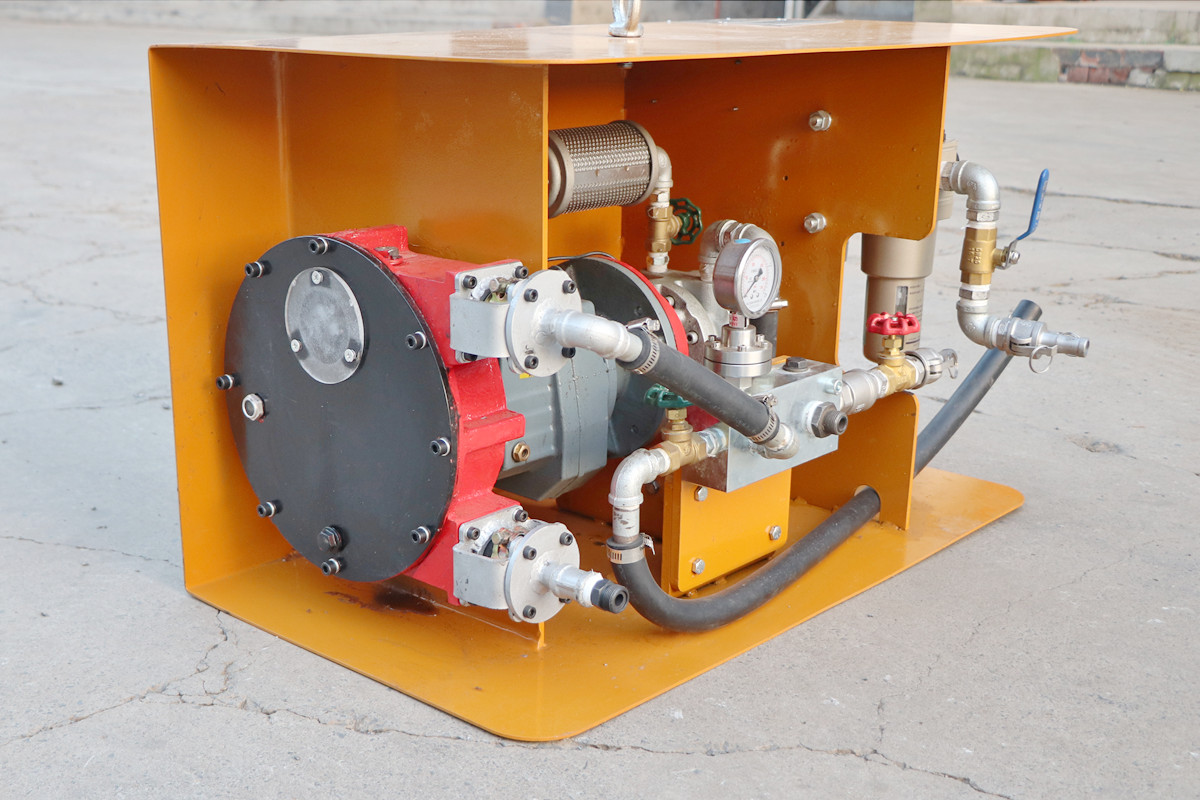

Additive dosing pump for shotcrete machine

An additive dosing pump for a shotcrete machine is an essential component used to accurately meter and inject chemical additives (such as accelerators, retarders, plasticizers, or other admixtures) into the concrete mix during the shotcrete process. These additives can modify the setting time, workability, strength, or other characteristics of the shotcrete, making the pump a critical tool in tailoring the mix to the specific requirements of a project.

Key Features of an Additive dosing pump for shotcrete machine:

1. Precision Dosing:

– The pump must deliver a highly accurate and consistent amount of additive to ensure uniform concrete properties. Even small variations in dosing can significantly affect the performance of shotcrete, particularly in terms of curing time and final strength.

2. Adjustable Flow Rates:

– The flow rate of the additive needs to be adjustable to accommodate different project requirements. Depending on factors like temperature, shotcrete mix composition, and site conditions, the operator may need to adjust the amount of additive being dosed.

3. Chemical Resistance:

– Since the additives used in shotcrete can include corrosive materials such as accelerators (often alkali-based) or retarders, the pump must be constructed from materials that are highly resistant to chemical attack, such as stainless steel, PVDF (polyvinylidene fluoride), or PTFE (polytetrafluoroethylene).

4. Synchronization with Shotcrete Machine:

– The additive dosing pump is often integrated with the shotcrete machine, and its operation needs to be synchronized with the machine’s output. This ensures that the right amount of additive is injected at the right moment, maintaining consistent properties throughout the shotcrete process.

– **Automation and control systems**: Modern dosing pumps often have programmable control systems that allow for automated adjustments based on the real-time feedback from sensors or operators.

5. *ressure and Flow Capacity:

– The pump should be able to handle the flow rate and pressure requirements of the shotcrete machine. Depending on the size of the operation, the dosing pump may need to deliver additives at higher pressures to maintain the proper ratio with the concrete mix.

6. Durability and Maintenance:

– Given the often rugged conditions in which shotcrete machines operate (tunnels, mines, slopes, etc.), dosing pumps need to be durable and reliable. Regular maintenance is required to ensure longevity, especially when handling aggressive chemical additives.