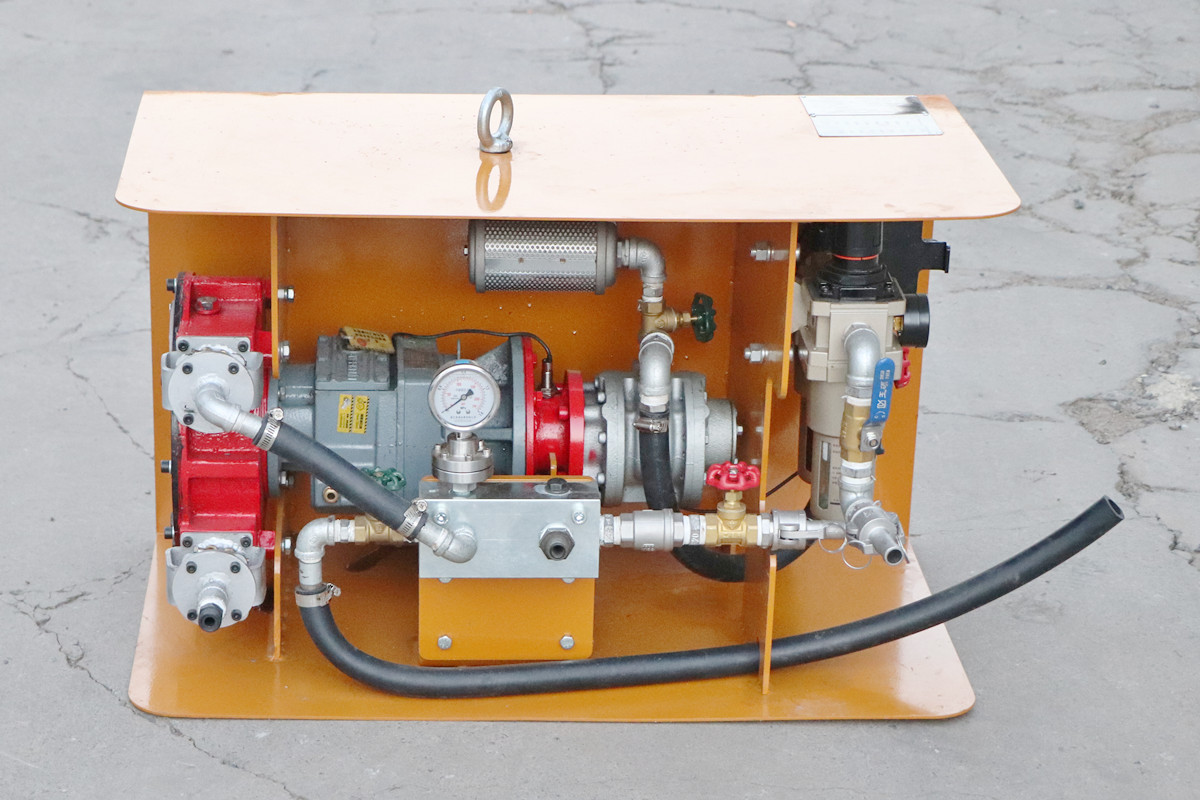

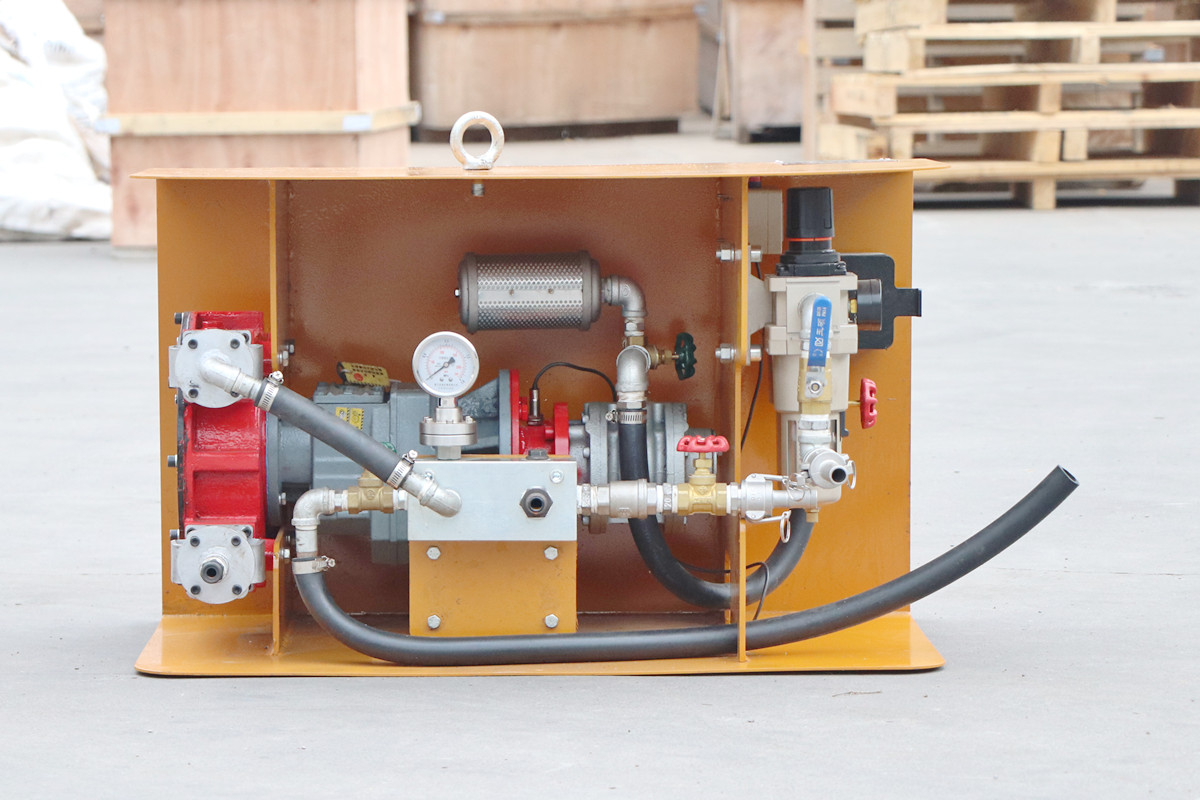

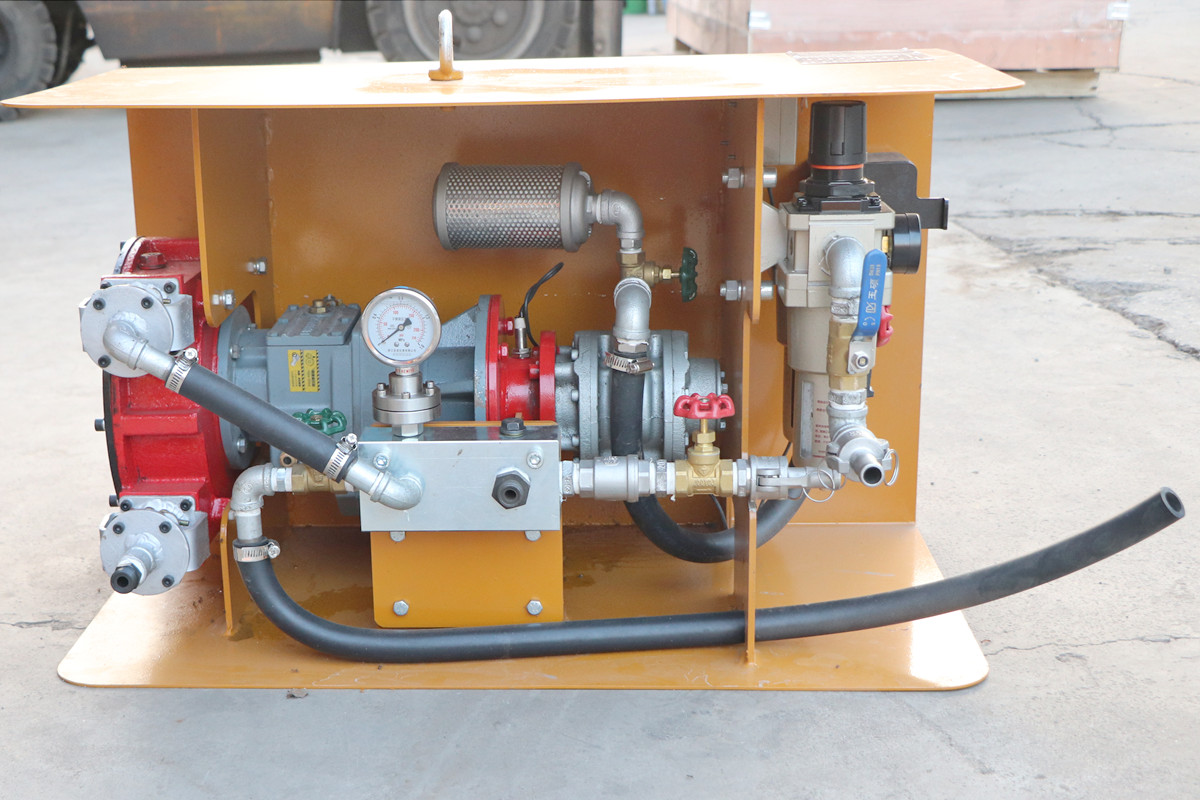

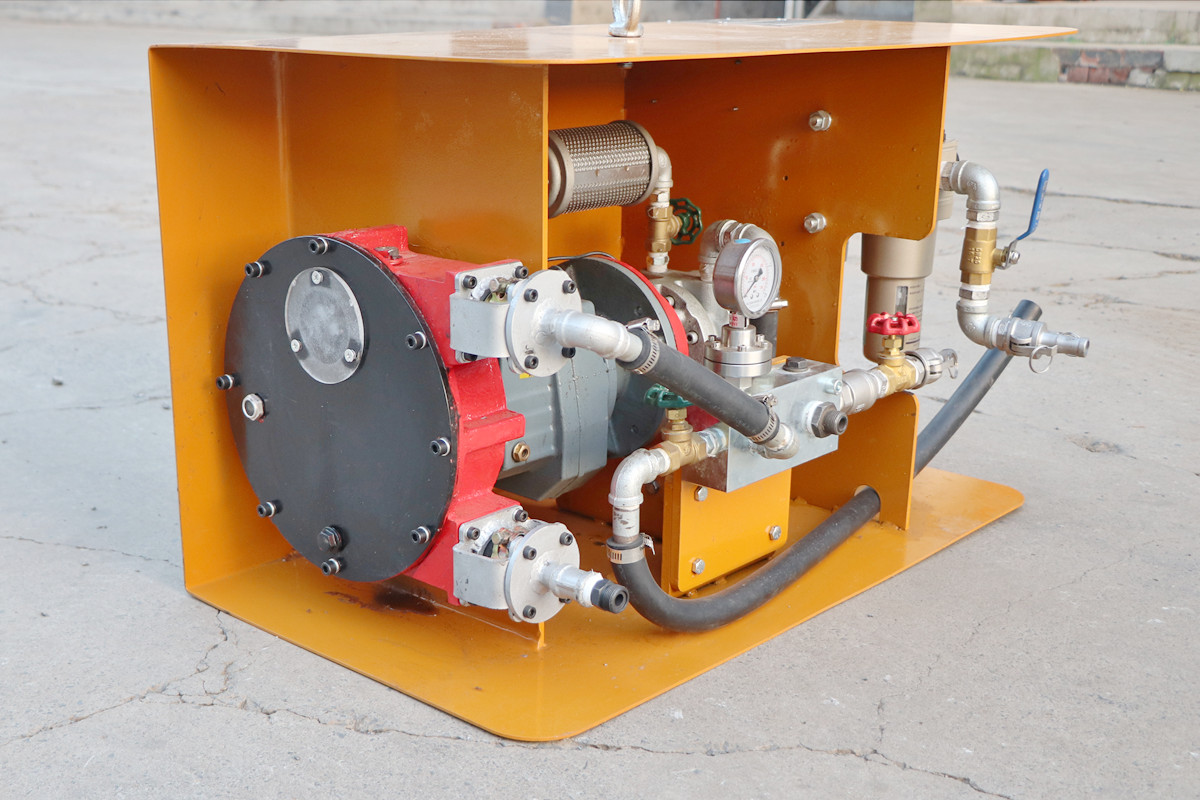

Accelerator for shotcrete machine

Accelerators for shotcrete machine are often used to improve the working efficiency of shotcrete machines by accelerating the spraying speed of concrete so that the concrete can be covered and cured on the working surface more quickly. This can not only shorten the construction time, but also improve the construction quality and efficiency.

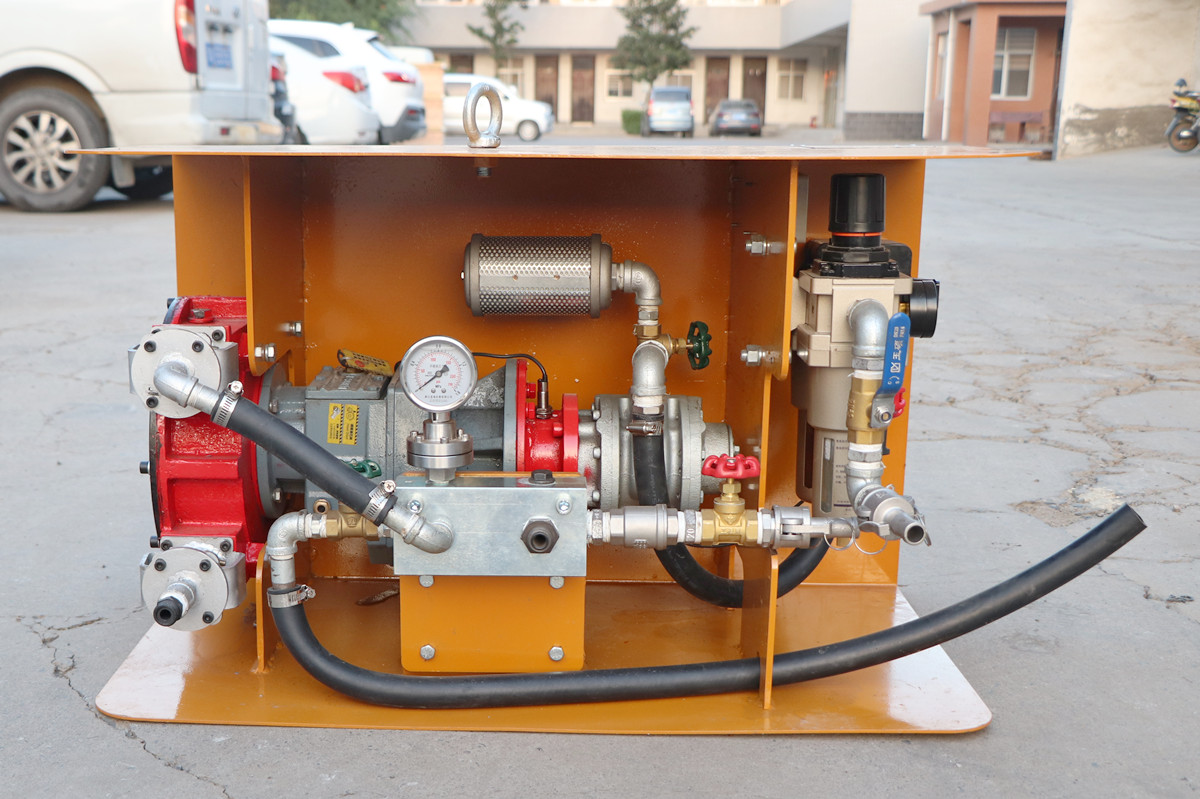

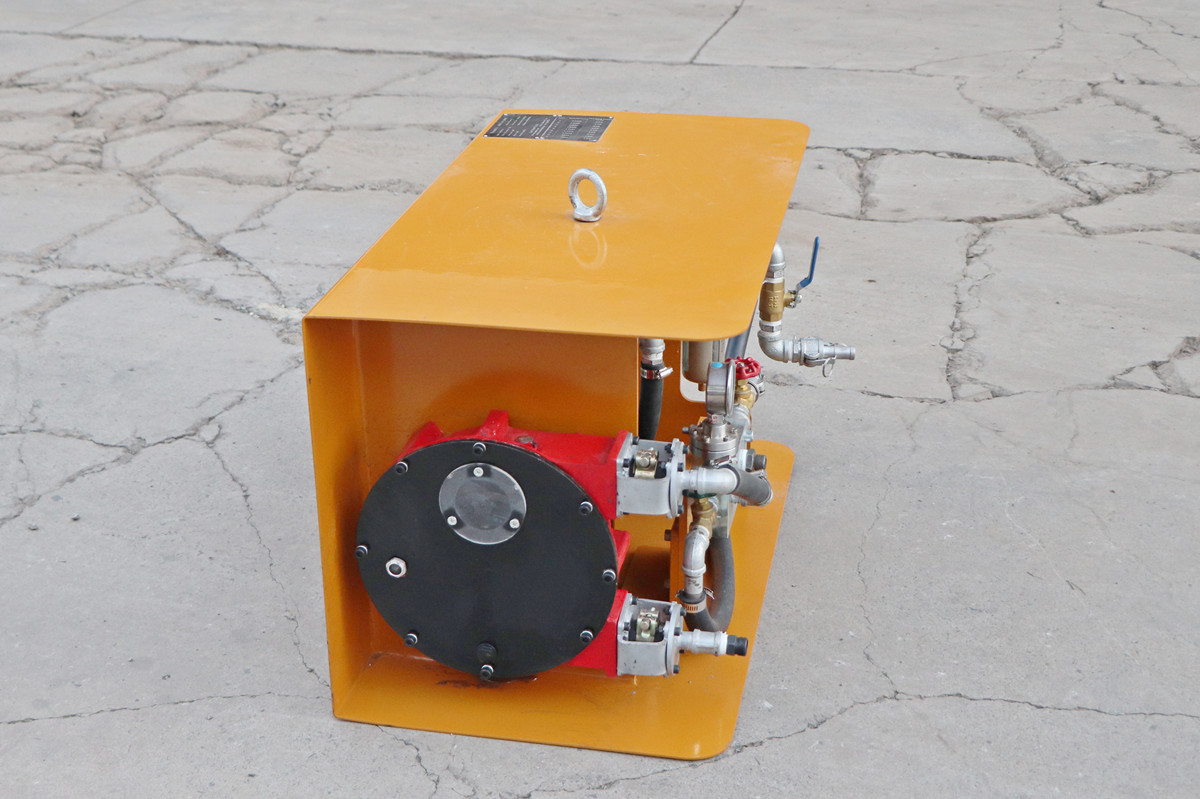

The working principle of the accelerator for shotcrete machine may vary depending on the different types of shotcrete machines and accelerators. Generally speaking, the accelerator accelerates the shotcrete mixture by increasing the pressure or velocity of the concrete mixture. This may involve complex mechanical, hydraulic or pneumatic systems that require precise design and control to ensure safety and efficiency.

Types of accelerator for shotcrete machine:

Hydraulic accelerators: Use the pressure of the hydraulic system to accelerate the spraying of concrete. This type of accelerator is generally more reliable and stable and suitable for a variety of construction environments.

Pneumatic accelerators: Use compressed air or gas to push the concrete mixture to achieve spraying acceleration. Pneumatic accelerators may have higher flexibility, but may require more maintenance and upkeep.

Mechanical accelerators: Use mechanical force to accelerate the spraying of concrete. This type of accelerator may be suitable for specific construction scenarios, but may require more space and operating skills.

Selection and use of accelerators:

When selecting and using accelerators, the following factors need to be considered:

Construction requirements: Select the appropriate type and specification of accelerator according to specific construction requirements. For example, for construction scenarios that need to cover a large area quickly, it may be necessary to select an accelerator with a higher spraying speed.

Safety and reliability: Ensure that the accelerator has sufficient safety and reliability to prevent failures or accidents during construction.

Maintenance and care: Understand the maintenance and care requirements of the accelerator to ensure its long-term stable operation.

Cost-effectiveness: Consider the cost-effectiveness of the accelerator, including purchase cost, operating cost, and maintenance cost.