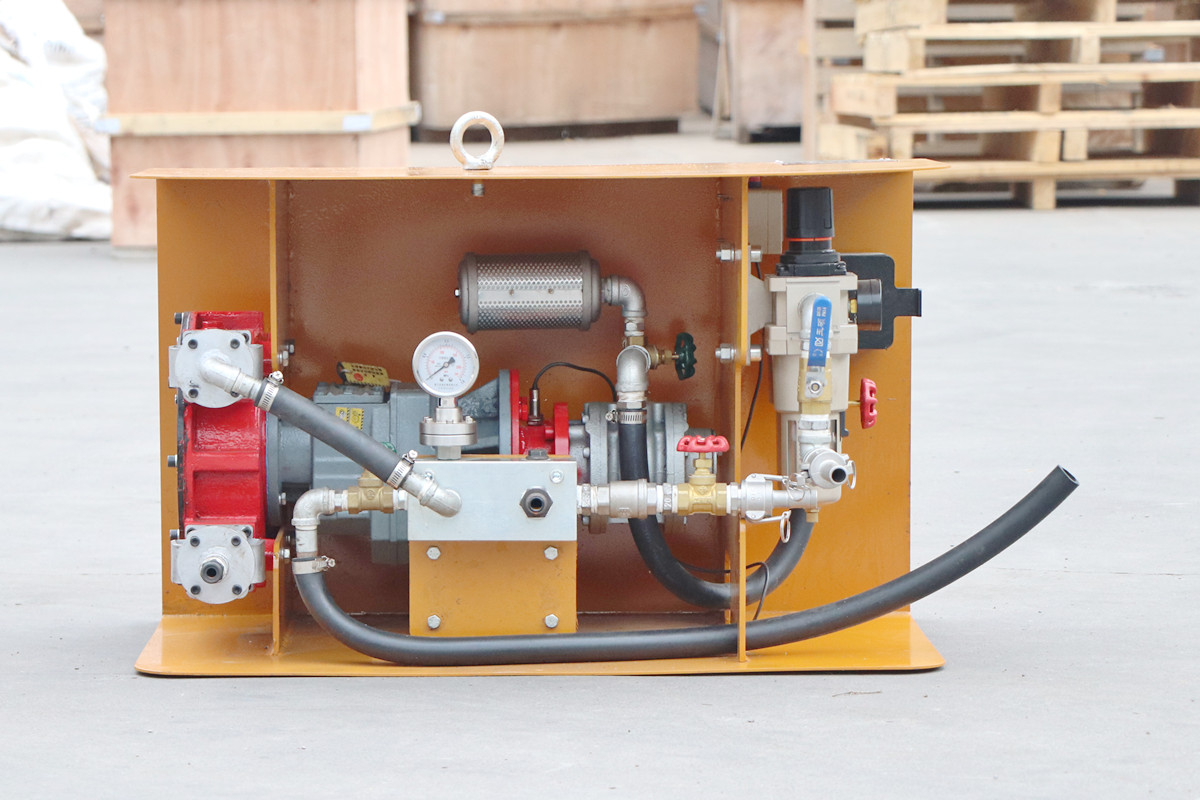

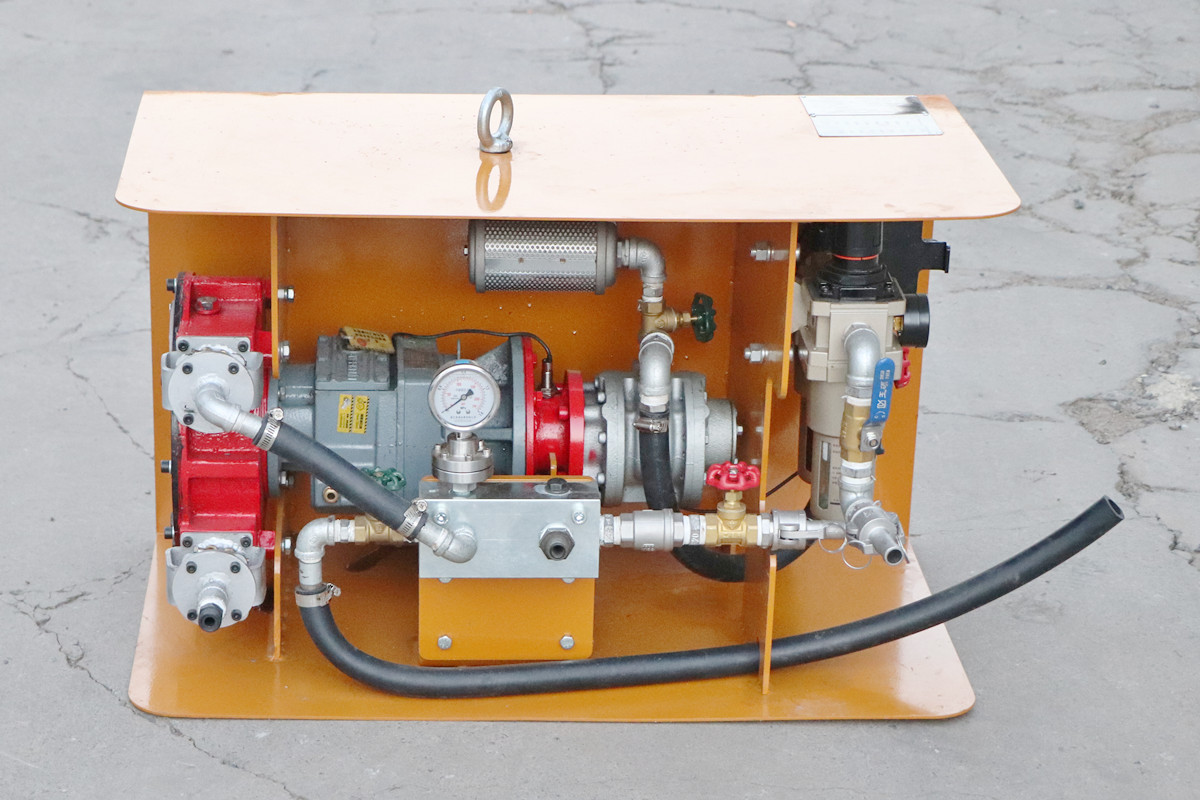

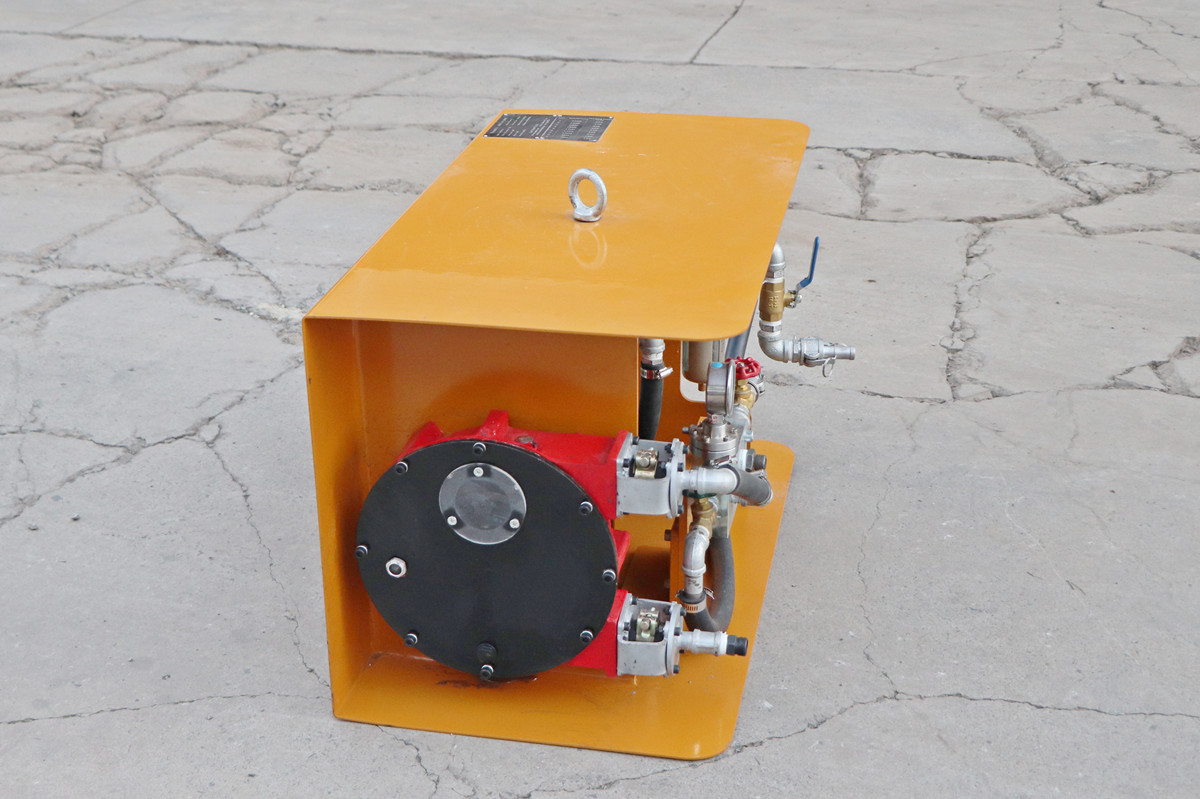

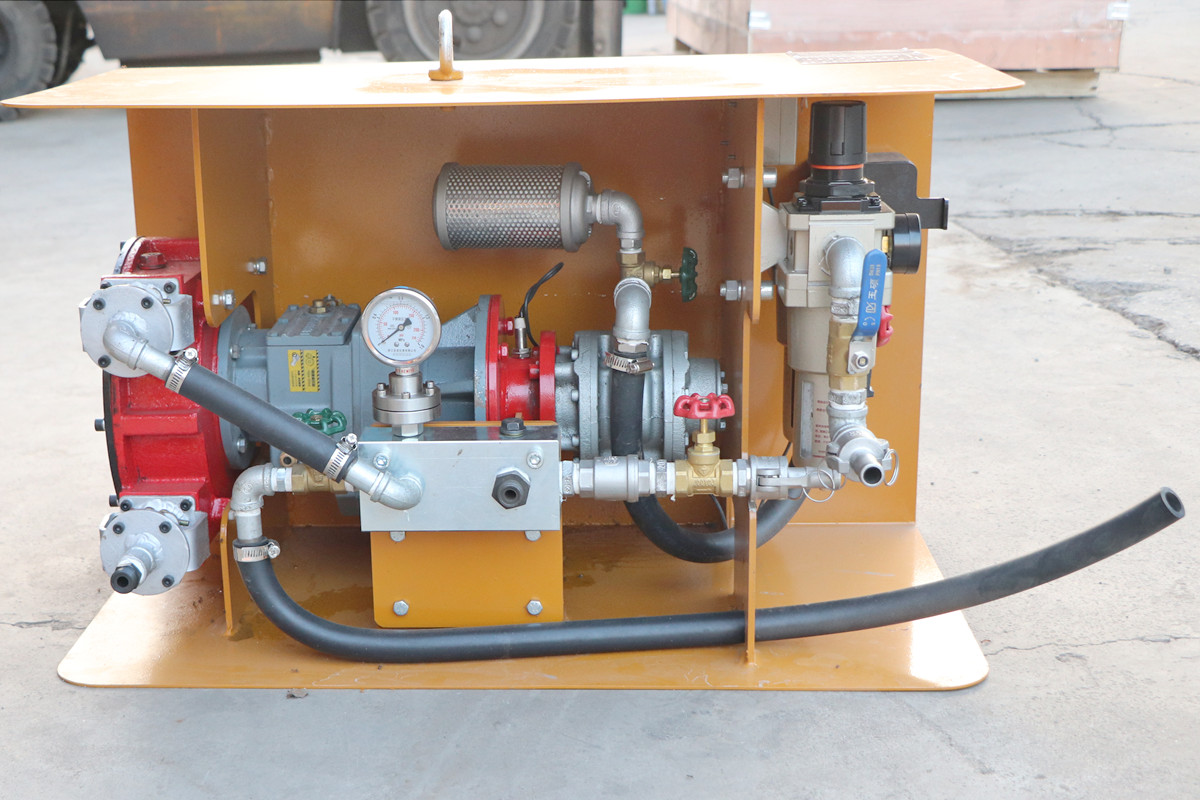

Accelerator dosage pump (dry or wet) shotcrete system

In shotcrete systems, the accelerator dosage pump plays a critical role in precisely metering and injecting accelerators into the concrete mix. The choice between dry and wet accelerator dosing depends on the specific requirements of the project and the properties of the accelerator used.

Accelerator Dosage Pump (Dry or Wet) Shotcrete System refers to the accelerator dosing pump used in the shotcrete system, which can accurately measure and deliver the accelerator in the dry or wet shotcrete system according to the construction requirements. The following is a detailed analysis of the system:

1. System Overview

The accelerator dosing pump is an important part of the shotcrete system. It is responsible for accurately measuring and delivering the accelerator (a chemical additive that can accelerate the setting of concrete) to the mixing system of the shotcrete. According to the different shotcrete construction methods, the system can be divided into two types: dry shotcrete system and wet shotcrete system.

2. Dry shotcrete system

In the dry shotcrete system, the accelerator dosage pump delivers the accelerator to the shotcrete equipment together with the dry concrete materials (such as cement, aggregate, etc.). These materials are mixed with water during the shotcrete process to form shotcrete. The advantages of the dry shotcrete system include simple equipment, easy movement and operation, and the ability to handle drier concrete materials. However, since the water and concrete materials are mixed during the shotcrete process, higher shotcrete pressures and more sophisticated mixing control may be required.

3. Wet shotcrete system

In the wet shotcrete system, the accelerator batching pump adds the accelerator to the pre-mixed wet concrete. This wet concrete has been fully mixed with water during the delivery process, so it has better fluidity and plasticity. The advantages of the wet shotcrete system include high shotcrete quality, uniform concrete strength, low rebound, and the ability to handle more complex geological conditions. In addition, the wet shotcrete system can also achieve effective injection at lower pressure.

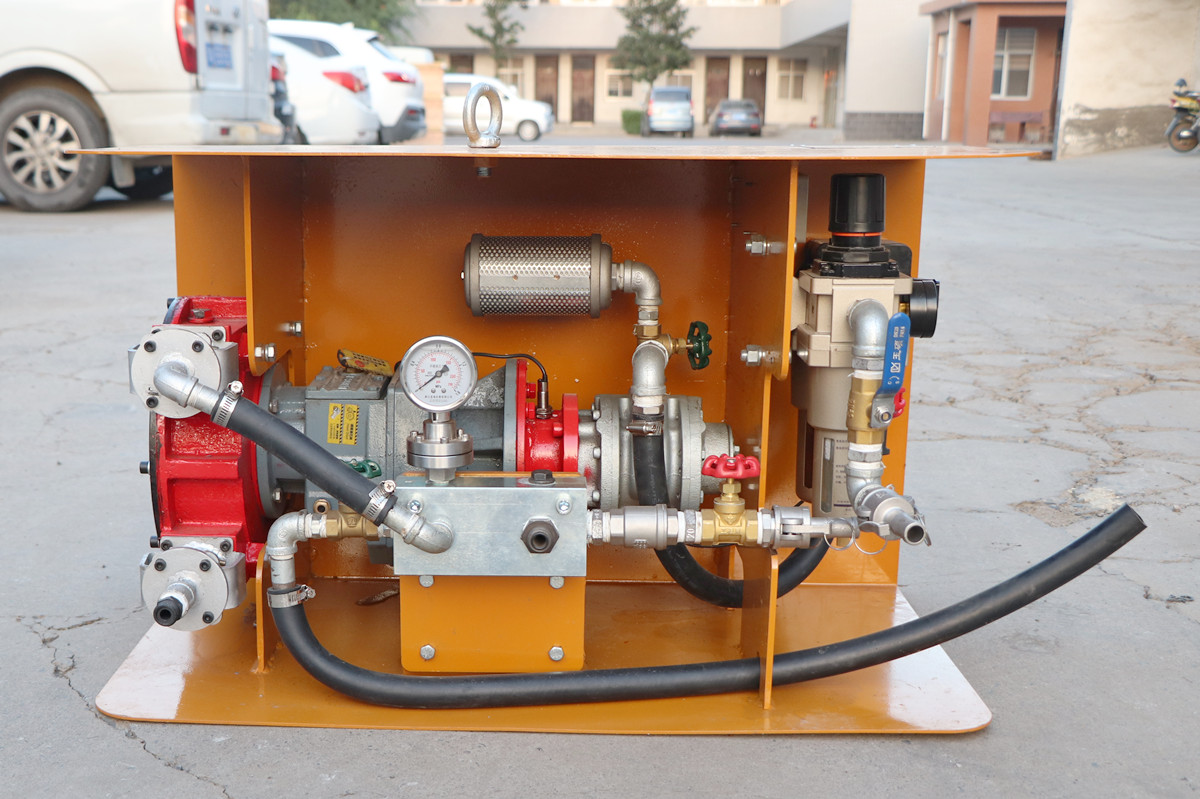

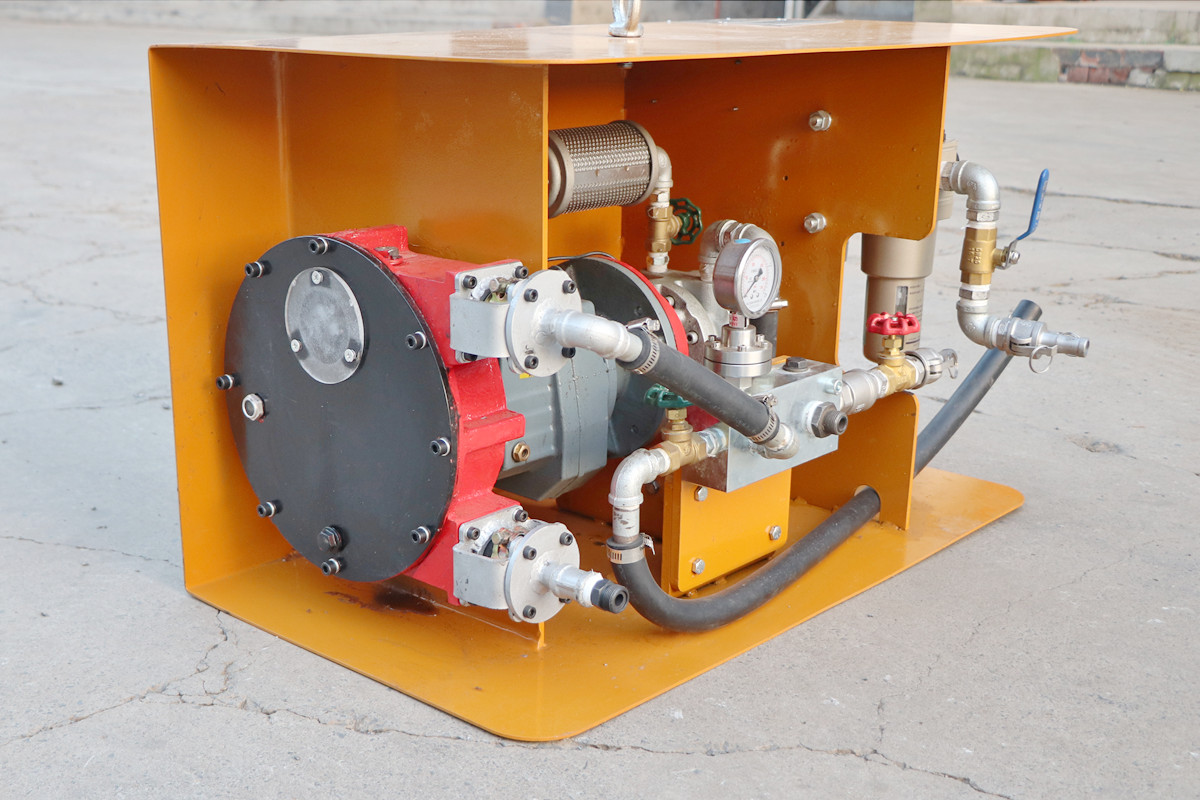

4. Working principle of accelerator batching pump

Accelerator batching pumps usually adopt the working principle of positive displacement pumps or metering pumps, which can accurately control the amount of accelerator. During the operation of the pump, the accelerator is sucked into the pump cavity and then metered and delivered by precise metering mechanisms (such as gears, screws or pistons). These pumps usually have adjustable displacement to meet different construction needs.

5. System application and precautions

Application: Accelerator batching pumps are widely used in shotcrete construction of tunnels, subways, mines, water conservancy, construction and other projects. It can improve construction efficiency, ensure project quality, and play an important role in various complex geological conditions.

Notes:

When selecting an accelerator dosage pump, comprehensive consideration should be given to the construction requirements, concrete material type, and type of injection system.

During use, the accelerator dosage pump should be regularly inspected and maintained to ensure its normal operation and extend its service life.

Attention should be paid to the type and dosage of the accelerator to avoid negative effects on concrete performance.

In summary, the Accelerator Dosage Pump (Dry or Wet) Shotcrete System is one of the indispensable equipment in shotcrete construction. It can improve construction efficiency, ensure project quality, and play an important role under various complex geological conditions. When selecting and using the system, factors such as construction requirements, concrete material type, and system type should be fully considered to ensure the best construction effect.