750 litre concrete mixer

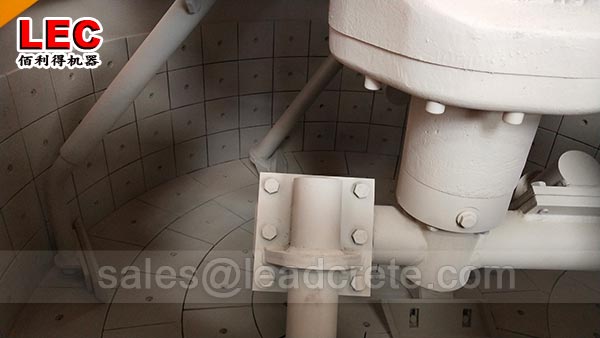

The mixing device of the 750 litre concrete mixer can choose appropriate materials according to the properties of the material, such as the material of the lining plate and the material of the mixing blade. The stirring blade is designed as a parallelogram structure. After using for a period of time, the blade can be turned over and used again, reducing the cost of use.

The technical characteristics of the 750 litre concrete mixer are: vertical structure, with planetary stirring device, the mixing and stirring of rotation and revolution generates a strong mechanical force, driven by the force, the refractory material moves rapidly and repeatedly in the machine, which accelerates the uniformity of the material. sex. The material, driven by a single motor, promotes the efficient mixing of materials, greatly improves the mixing uniformity, and has powerful technology and functions, which can better present the quality of materials to users. Refractory mixers can be used on production lines.