500L 500kg capacity planetary mixer for refractory material

The advantages of the 500L 500kg capacity planetary mixer for refractory material are obvious to all, and it is deeply loved by users in the industry. The 500kg capacity planetary mixer for refractory material is also recognized in ultra-high performance concrete for its high homogeneity treatment characteristics.

The application of a 500L 500kg capacity planetary mixer for refractory material promotes the development of high-end, intelligent, and green industries. The characteristic design provides a technical basis for the expansion of the use of mixers. The variety of mixer models is convenient for layout and use.

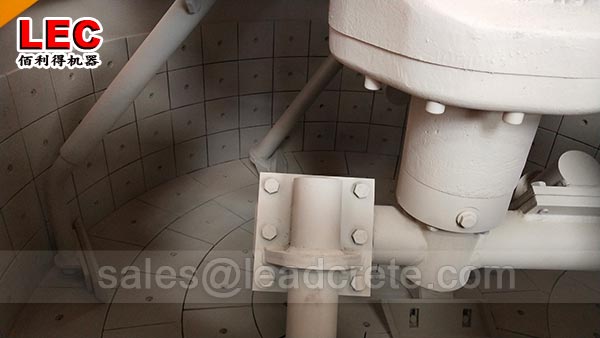

The 500L capacity planetary mixer for refractory material operates with variable frequency and speed regulation, and the equipment is preset in advance or the speed is adjusted during the production process. The mixing movement completed by the mixer is multi-directional, without dead angle processing, and the mixing quality meets various production needs.

There are many types of planetary mixers for refractory material, and the most popular one in the industry is a planetary mixer for refractory material. The planetary refractory mixer solves the problem of uneven mixing in the refractory industry and is an ideal mixing equipment for the industry.

The 500L 500kg capacity planetary mixer for refractory material adopts a vertical disc design and operates through a planetary mixing method, which can complete uniform mixing in all directions without dead ends, and there is no leakage of mixing materials and the work efficiency is very high.

Application of planetary refractory mixer:

Shaped refractory products: raw material preparation of refractory bricks, lightweight refractory bricks, high-temperature mixtures, and granular materials for rolling products.

Unshaped refractory products: ramming material, castable material, spray coating, high-temperature insulation material, heat insulation material, refractory mud

Refractory prefabricated parts: ceramic fiber materials, mixtures of various types of ceramic materials