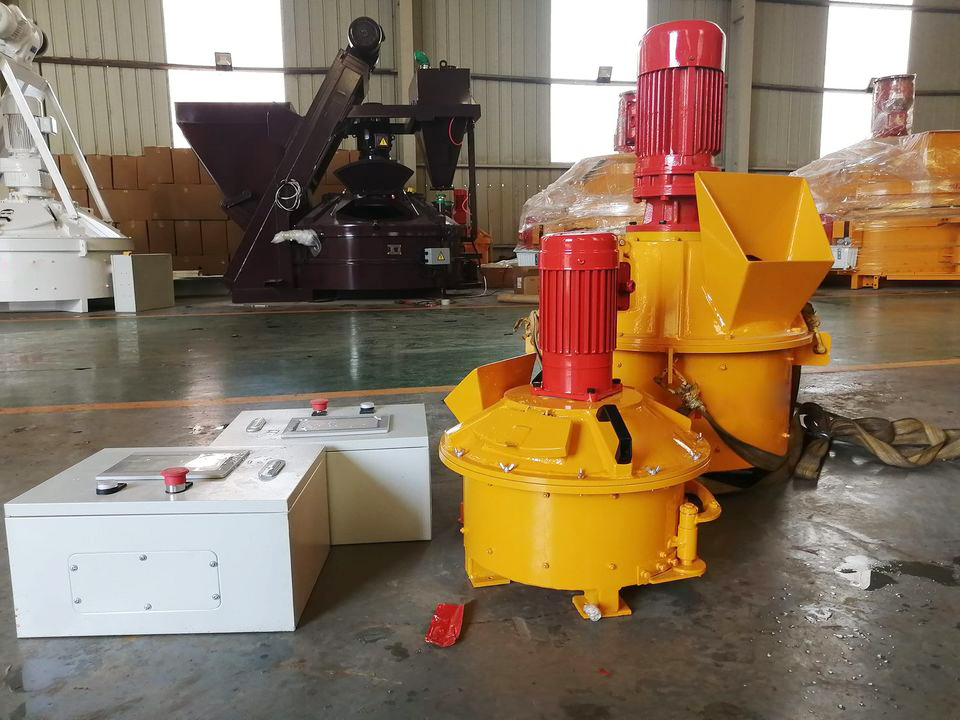

3 party new vertical shaft planetary mixer

3 party new vertical shaft planetary mixer with mixing blades high nickel alloys are more resistant to wear, while a polyurethane blade optional.

3 party new vertical shaft planetary mixer is suitable for mixing all high-quality concrete (dry, rigid, semi-rigid and plastic concrete) and in the shortest time to reach high homogeneity, can be applied to glass, ceramics, refractories and other industries.

Forced mixing of 3 party new vertical shaft planetary mixer is realized by a compound motion of extrusion and flipping driven by rotating planets and blades. The mixing blades are designed as a parallelogram structure (patent), which can be rotated and reused to improve the availability and service life of the blades. The special discharge scraper is designed according to the discharge speed to improve production efficiency.