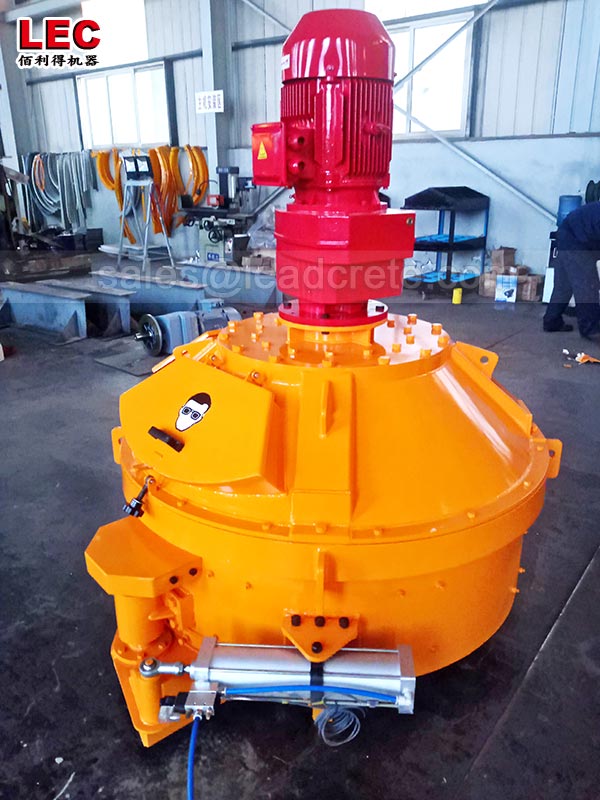

1250L concrete mixer machine

Leadcrete Equipment is 1250L concrete mixer machine supplier and manufacturer in China, any need a 1250L concrete mixer machine, you can contact us freely.

1250L concrete mixer machine can not only meet the mixing needs, but also give better play to the characteristics of materials to achieve a more uniform mixing effect. Single motor drive mode ensures continuous and synchronous output of materials. There can be enough layout space.

With the unique planetary mixing track, the material mixing can be realized layer by layer, and the combination of rotation and revolution can realize efficient, high and uniform mixing. The fast, convenient and reliable mixing device 1250L concrete mixer machine has strong durability and high-quality characteristics. In terms of equipment use, customers can customize special 1250L concrete mixer machine according to their needs to complete the uniform distribution of material components.