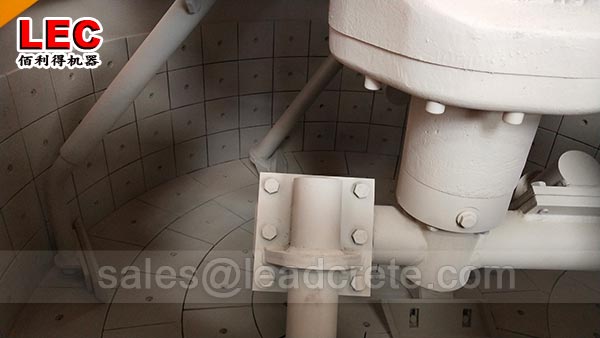

1000L 1500L 2000L 2500L planetary concrete mixer

The 1000L 1500L 2000L 2500L planetary concrete mixer has strong processing power for viscous materials. For uhpc ultra-high performance concrete, which has a certain viscosity, high friction and high strength, the processing uniformity and speed are equally reliable.

1000L 1500L 2000L 2500L planetary concrete mixer has a good application effect, and related maintenance operations need to be done in the daily operation and use process, so as not only to ensure the long service life of the mixer but also to facilitate the high efficiency of the mixer in daily maintenance.

1. After each shift of the planetary concrete mixer, the scale and obstacles in each part of the mixer cavity should be cleaned up in time, and the bolts of each part should be checked and tightened. Replace the severely worn bolts and nuts.

2. When the oil level of each lubricating device such as the reducer lubricating oil of the planetary concrete mixer is insufficient, it should be replenished in time.

3. The planetary concrete mixer shall thoroughly clean the mixer after each shift, and put clean water and stones in the mixing drum, release it after running for 10-15 minutes, and then clean it with a broom.