Refractory concrete pan mixer for sale

2024-07-04 16:36:09

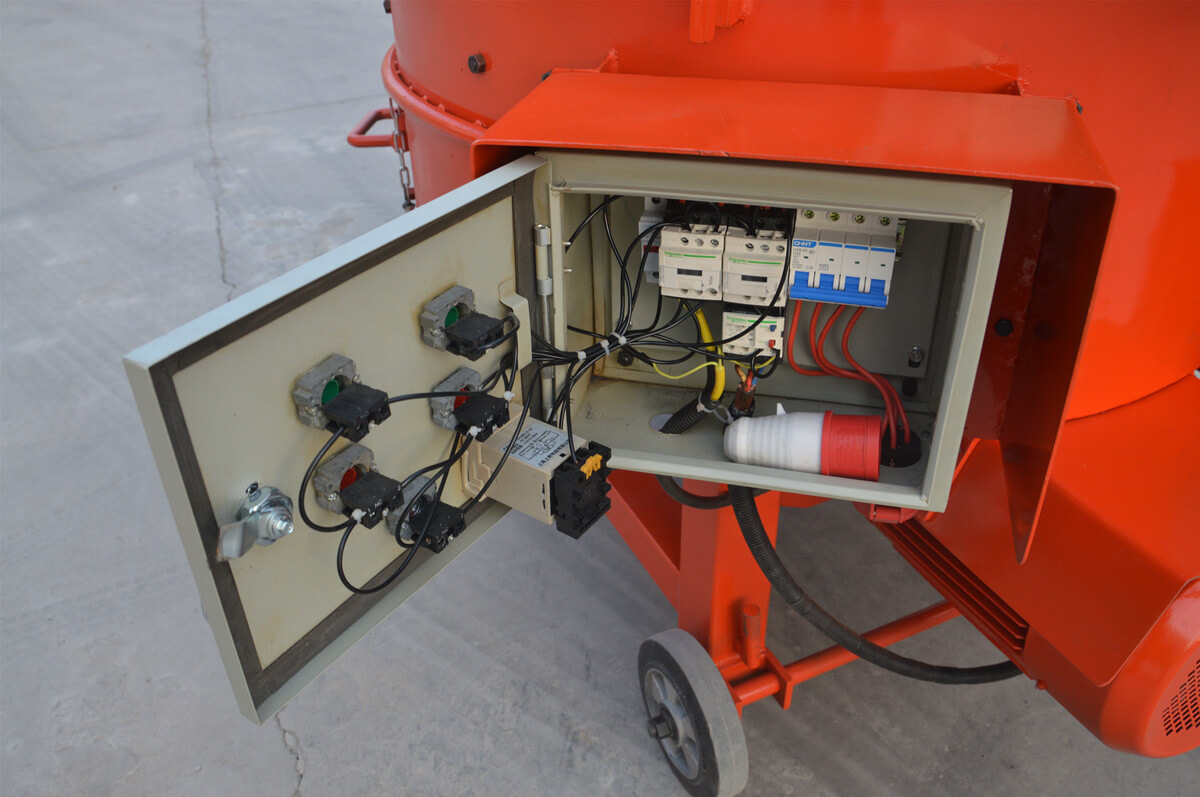

The refractory concrete pan mixer is composed of a feeding mechanism, a mixing mechanism, a discharging mechanism, a water supply system, an electric control system, etc. A pneumatic piston push rod is used during discharging to enable the motor to automatically discharge. Aggregates, crushed stones, sand and gravel, dry-mixed concrete, plastic concrete, light aggregate concrete and various mortars can be mixed. The two horizontal mixing shafts in the mixing drum of the machine rotate in opposite directions at a constant speed for mixing.

This refractory concrete pan mixer is currently an advanced and ideal model at home and abroad, with the advantages of high automation, good mixing quality, high efficiency, low noise, convenient operation, low energy consumption, fast discharging speed, long life of lining plates and blades, and convenient maintenance. It is suitable for mixing plastic, dry, light aggregate concrete and mortar, mortar.

Instructions that must be followed during operation:

1. After emergency stop, the material in the trough can be unloaded. It is strictly forbidden to start the machine with load;

2. Overload operation is not allowed;

3. Wear-resistant parts produced by our company must be used to avoid damage to the machine;

4. Stay away from the unloading area to avoid harm to workers.

5. After each shift, check the tightness of the nuts, clean the trough and tools, open and close the discharge door several times to ensure smooth operation, check the blades and tiles every week and replace them if necessary.

We can supply you with 100kg, 250kg, 300kg, 500kg, 750kg, 800kg and 1000kg mixing capacity high alumina castable refractory concrete pan mixer for sale with factory price. Email address: sale@leadcrete.com

Phone/Wechat

Phone/Wechat ADDRESS

ADDRESS